Unique know-how and leading process tools to help you reach your sustainability targets

Treated and recirculated process water results in lower fresh or raw water intake

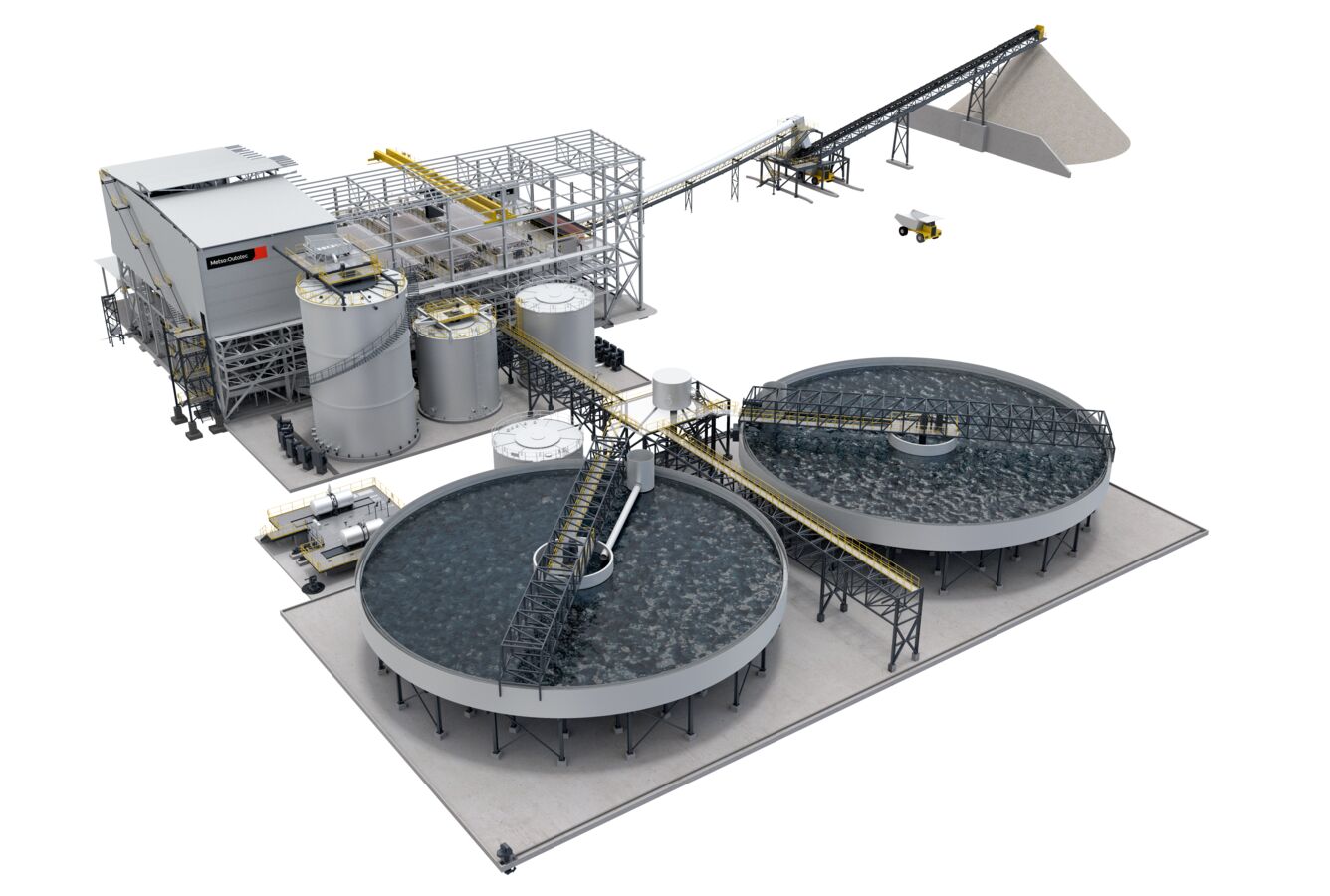

Metso tailings solutions includes solutions for conventional, thickened, high density, paste and filtered tailings as well as hybrid solutions

Metso offers technical and feasibility studies, test work on-site or the Metso laboratory as well as flowsheet development

The rising demand for sustainably mined materials is pushing the need for more advanced technologies.

Stricter environmental regulations are shifting the focus toward tailings management and water resource efficiency.

Modern mineral processing methods are required to improve the predictability and continuity of operations.

Metso offers holistic solutions for tailings processing, while reducing water use, environmental impact, risks, and costs.

We can support your mine's lifecycle from the beginning with studies, test work and flowsheet development. We have a comprehensive tailings offering including conventional, thickened, high density, paste and filtered tailings processing as well as hybrid solutions.

The future of mining depends on sustainable practices that contribute to the equitable development of the community and ecosystem while enabling modern life.

With the introduction of new-age dewatering technology, we are committed to offering productive and eco-efficient solutions to our customers.

We help mining companies not only to maximize water recovery but also help reduce the footprint of tailings dams.

- Up to 90% water recovery with high-performance filters

- Up to 85% reduced plant footprint with compact and efficient design of Inclined Plate Settler (IPS)

- Improved filtration efficiency into fine and coarse streams with MHC™ Series Hydrocyclone

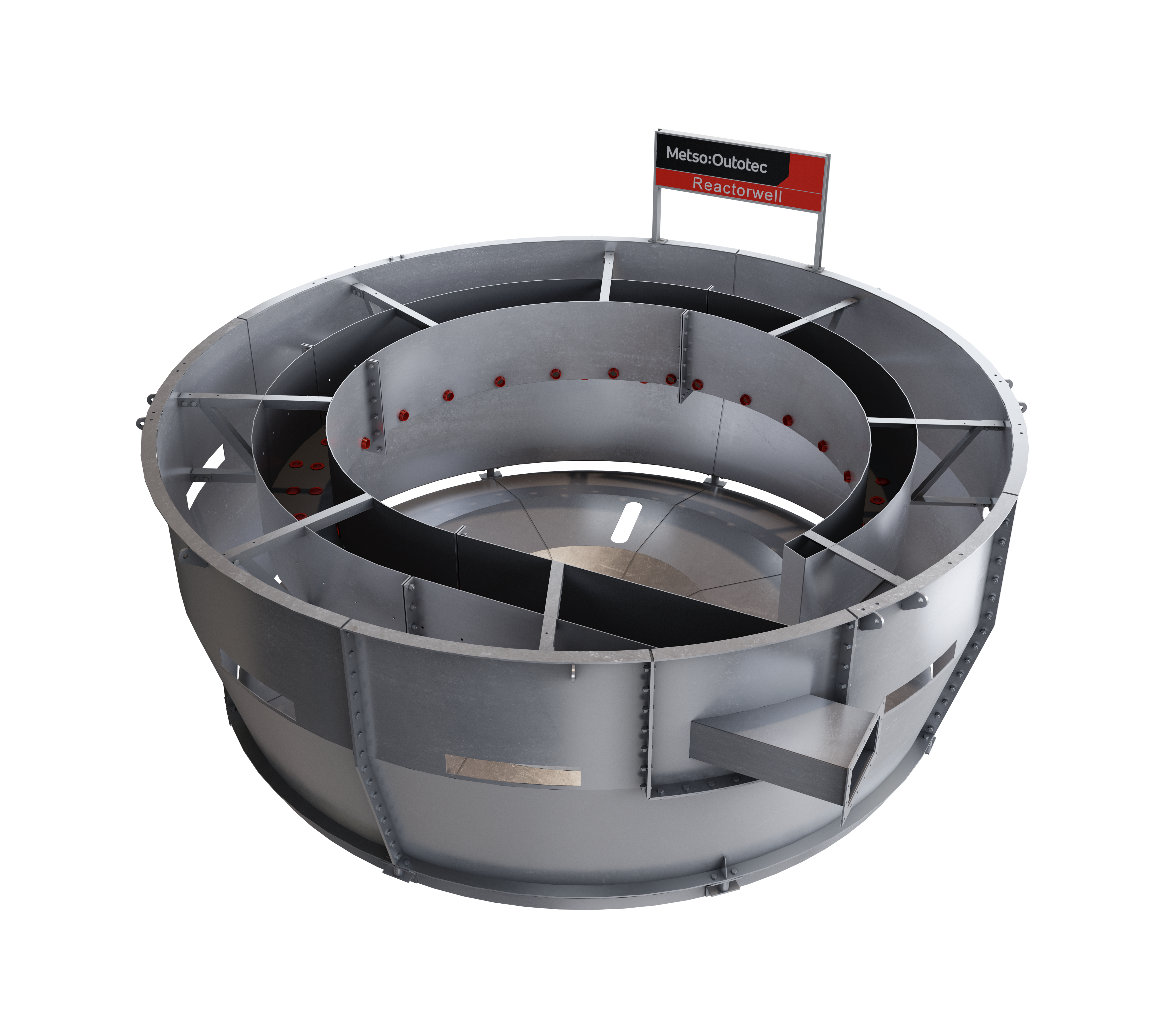

- Reduced reagents using thickeners with Reactorwell™ technology

Plant solutions

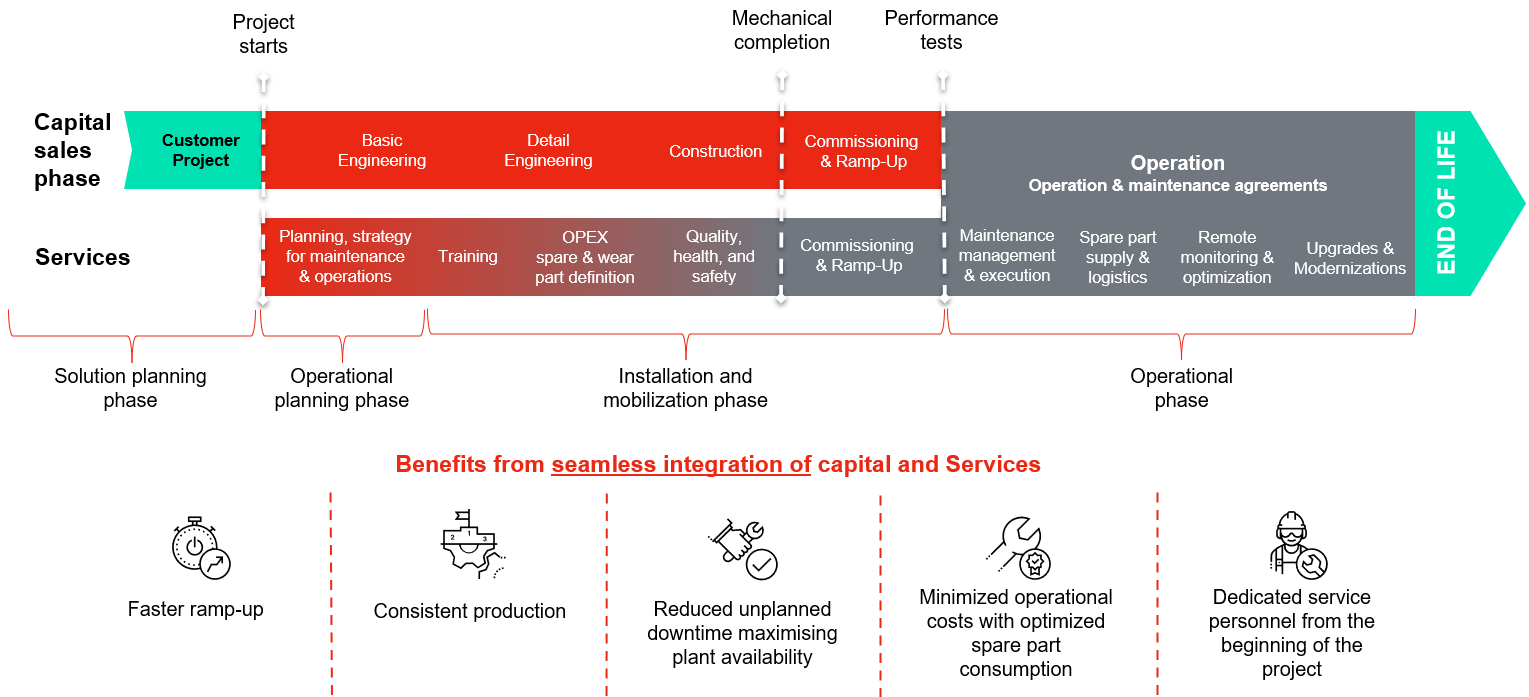

Filtration

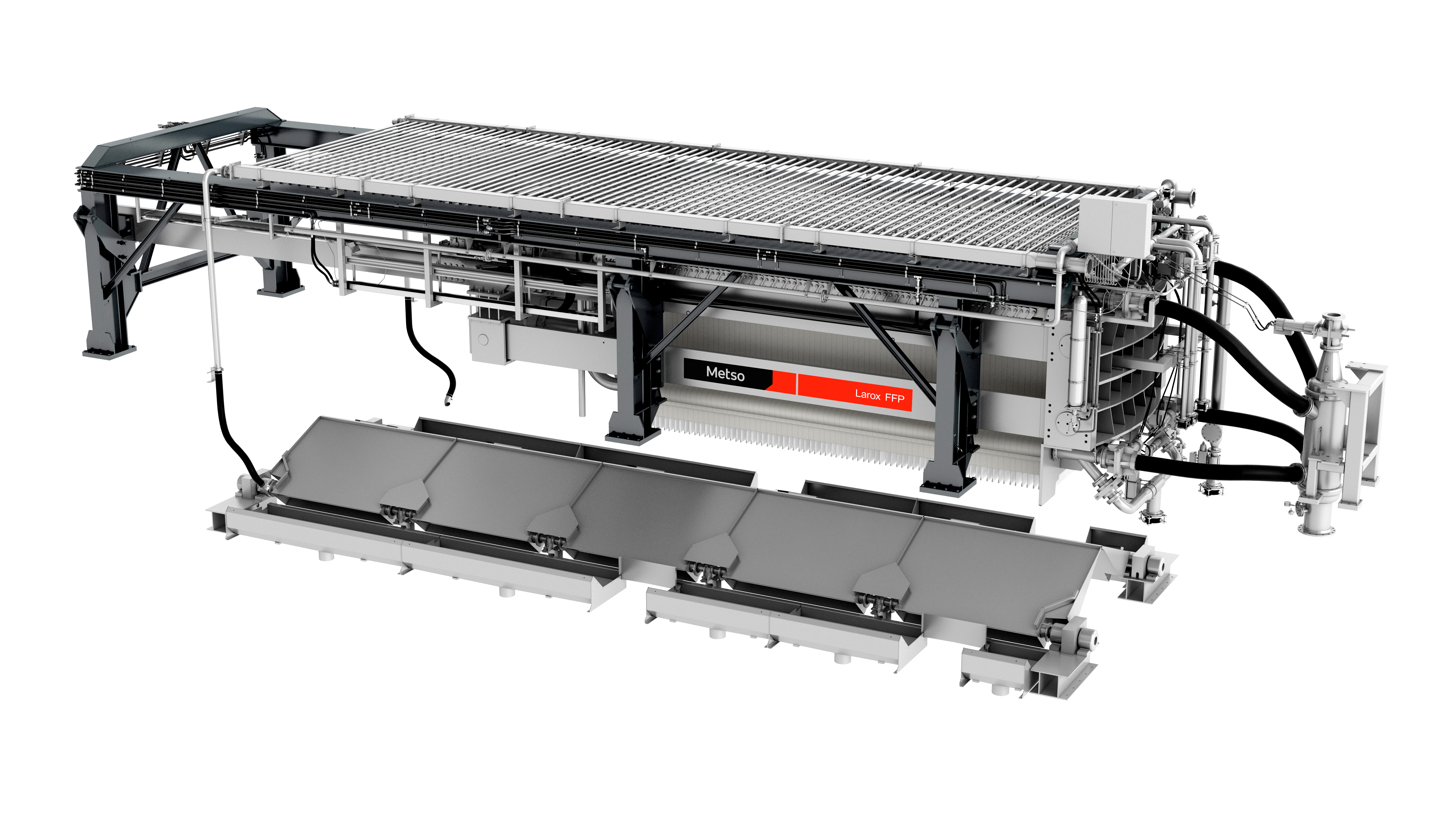

Thickening and clarifying

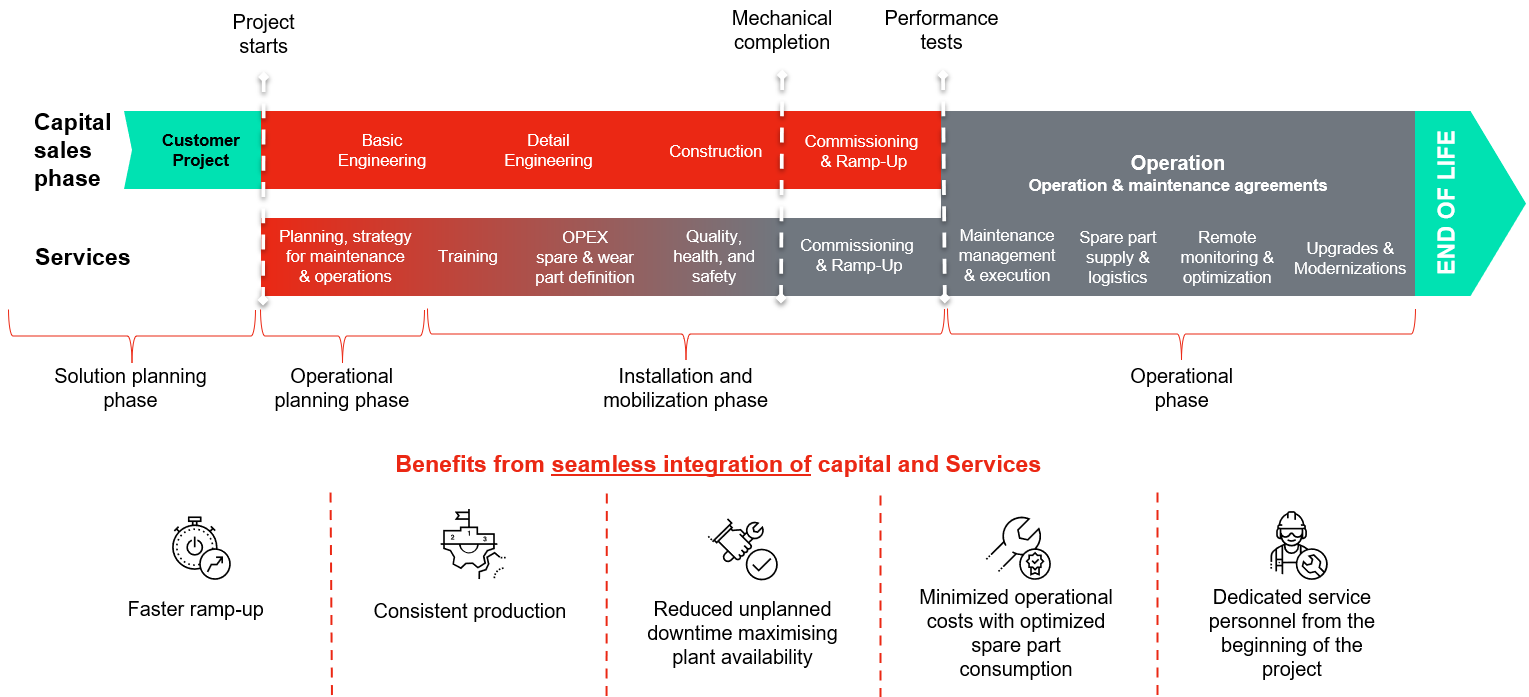

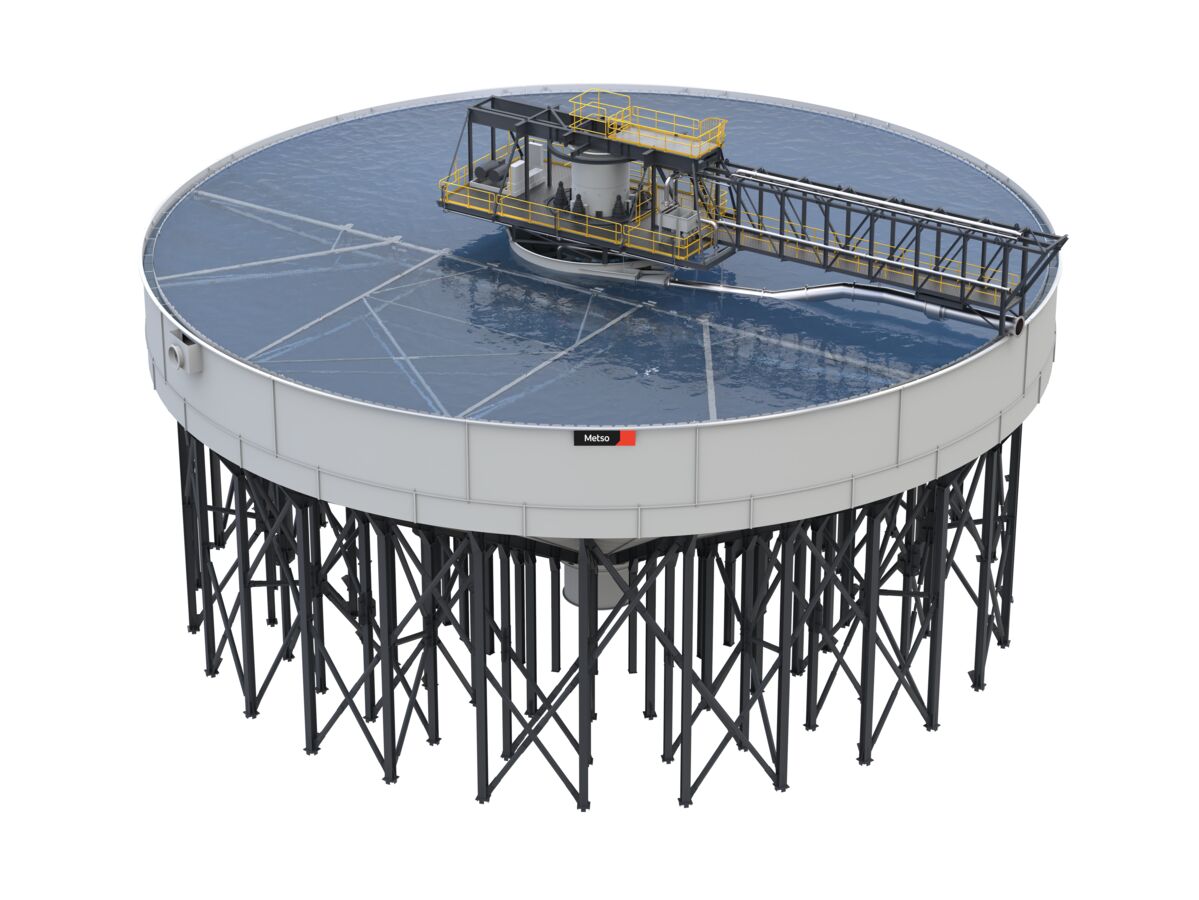

Seamless integration from investment to full life cycle