Metso HRC™ for Aggregates

HRC™ Series high pressure grinding rolls (HPGR) are most often utilized when the processed material is hard rock. However, they can also refine softer materials like industrial minerals. The smaller models of the HPGR are particularly productive in producing manufactured sand for asphalt and concrete production.

Versatile applications

Mining operations. Industrial minerals processing. Manufactured sand production for asphalt and concrete production.

Increased throughput

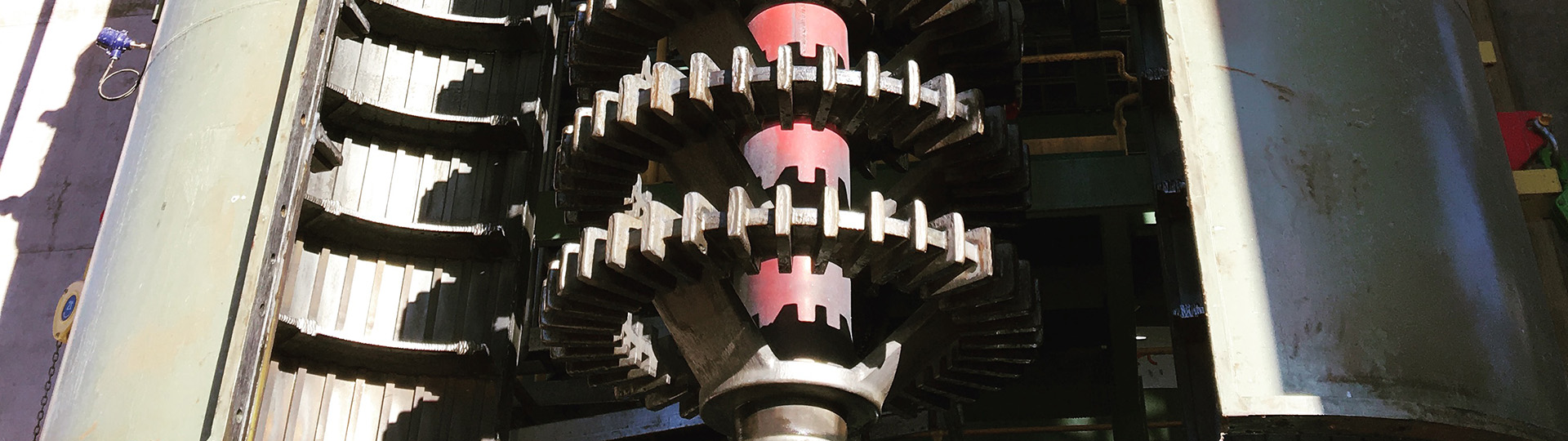

An intelligent flange design to maximize material intake. A patented arch-frame to eliminate downtime caused by skewing.

Reduced operating costs

No need for grinding media. Continuous material stream. Direct feed to the crushing zone.

Easy maintenance

Less required service. Design that allows changing critical parts simply and easily.

Check the video

00:00

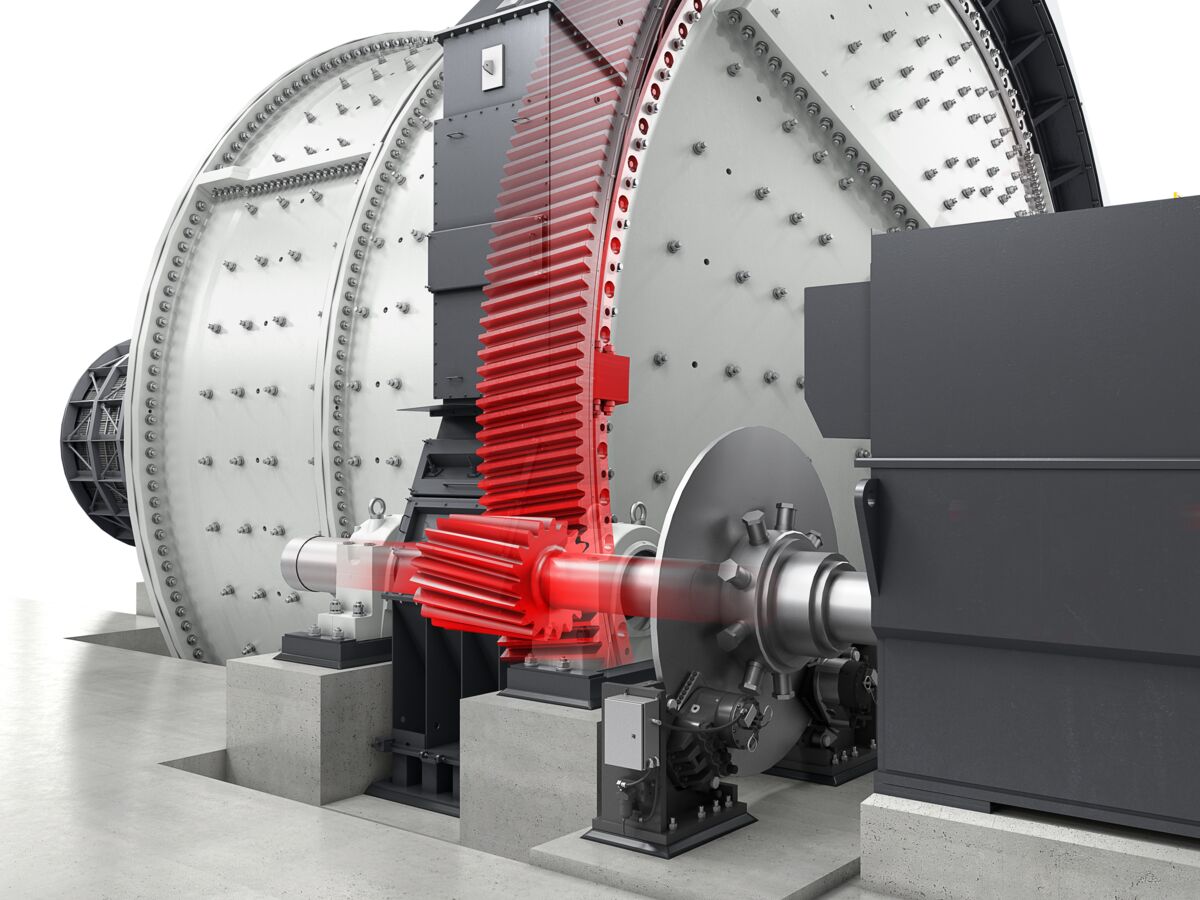

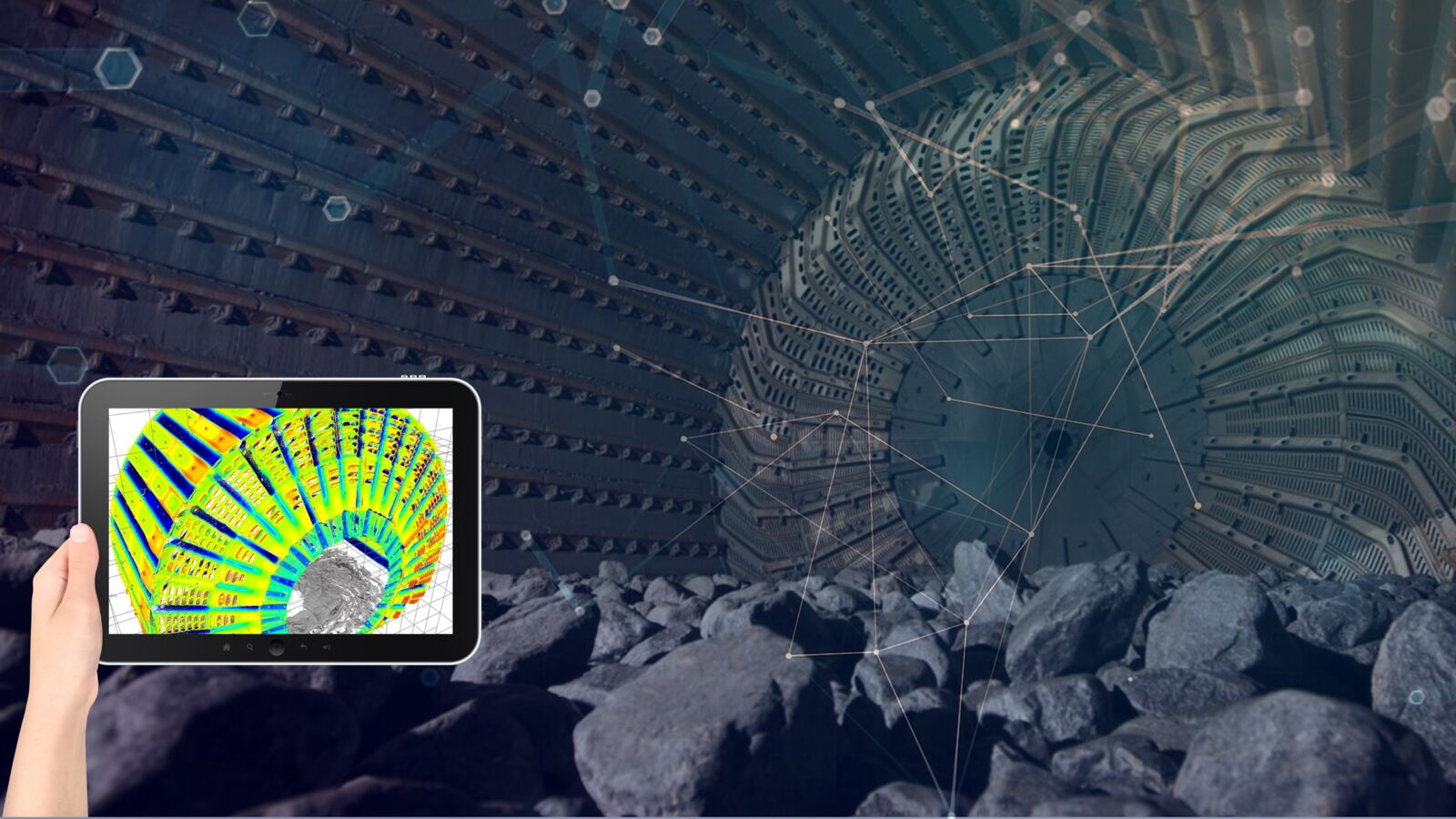

Evolution in grinding performance

How do you improve the industry standard for HPGRs? By taking proven grinding technology and a customer-focused evolution to enable superior grinding and energy efficiency.

Learn more information about the HRC™ e HPGR.

HRC™e HPGR for mining operations

The HRC™e HPGR helps you to get more value from every ton of ore with the sheer production capacity and state-of-the-art features.

They can be used in a wide range of mining applications:

- Hard rock

- Diamond

- Iron-ore

- Gold

- Copper

- Platinum

- Molybdenum

- Industrial minerals

- Others

HPGR for aggregates production

The smaller HPGR models, HRC™ 8 and HRC™ 800, are specifically designed to meet the needs of aggregate and industrial minerals applications.

They can produce high-quality manufactured sand for asphalt and concrete production.

Benefits

- High-quality cubical aggregate for all reduction ratios and fractions

- Consistent production

- Low noise and less dust generated

- Low energy and wear consumption

- Capability to process hard rock, soft rock, construction waste, and abrasive materials like limestone, river gravel, granite and basalt

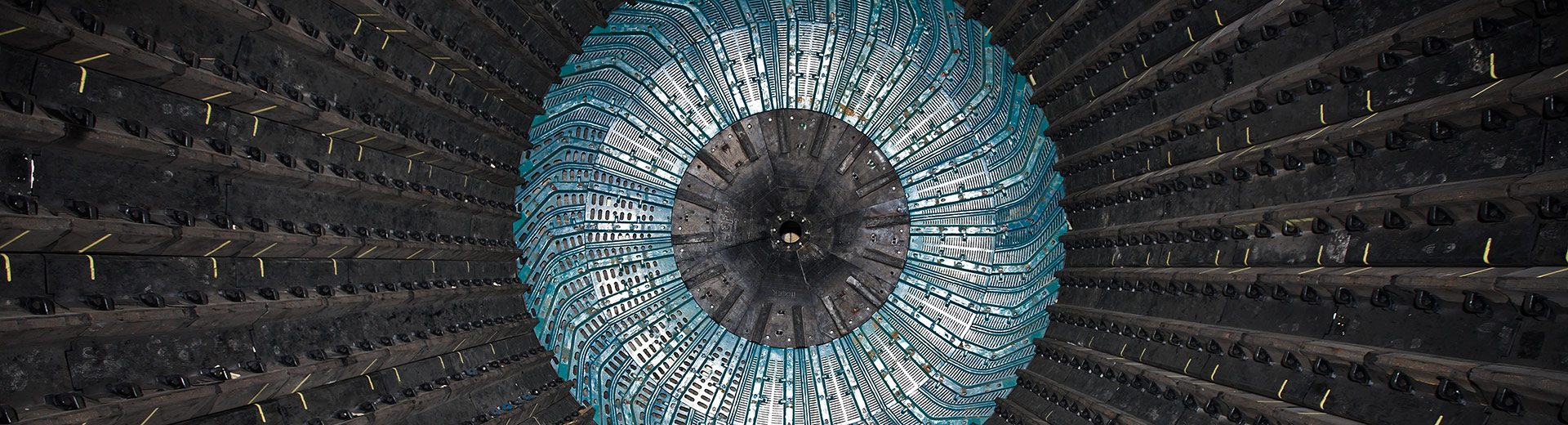

Robust HRC™ high pressure grinding rolls (HPGR)

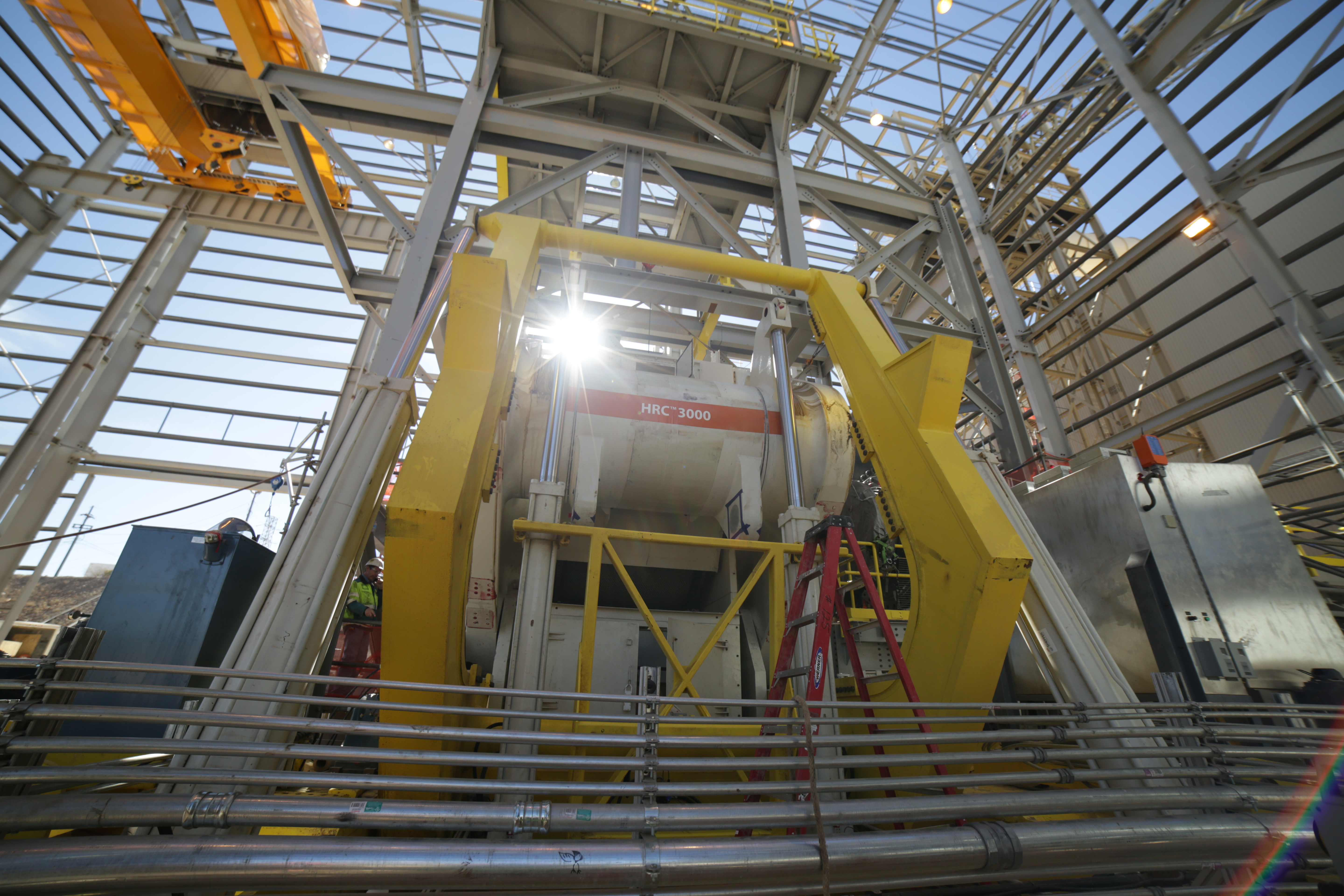

Building the world's largest HPGR

HRC™3000 is a new generation high-pressure grinding roll that eliminates issues found in traditional HPGRs, allowing the mining industry to reach a new level of energy efficiency.

The world's largest HPGR was installed at Freeport-McMoRan’s Morenci site in Arizona, USA.

Watch the video of the installation and visit a customer case Building the world’s largest HPGR to learn more.

Check the video

00:00

HRC™ HPGR technical specifications

MODEL | APPLICATION | TIRE DIMENSIONS | MAX MOTOR POWER | HEIGHT | LENGTH | WIDTH | CAPACITY |

|---|---|---|---|---|---|---|---|

| HRC™ 8 | Aggregates, mining | 800 mm x 500 mm | 2 x 75 kW (2 x 100 hp) | 1630 mm (64") | 2808 mm (111") | 3865 (152") | 60 - 90 tph |

| HRC™ 800 | Aggregates, mining | 800 mm x 500 mm | 2x100 kW, (2 x 147 HP) | 2400 mm (94") | 3700 mm (146") | 2700 (106") | 80 - 120 tph |

Grinding parts and services

Grinding customer cases, blogs & webinars

Customer cases See how our customers around the world have achieved success with our grinding products and services.

Blogs Want to broaden your knowledge of efficient grinding practices? These blogs are for you.

Webinars On-demand grinding webinars from our professionals in the industry.

Contact local sales experts

Select your industry to open the form.

Your information is safe. Check our privacy notice for more details.

Thank you!

We will shortly contact you. You can send a new inquiry again after 15 minutes.