Lokotrack® EC range online launch

Deep dive into the first models of the new Lokotrack® EC range and the aftermarket offering at our online launch event from October 23, 2024.

For minimum operational cost and CO2 emissions, the Lokotrack EC range features a next-generation diesel-electric powerline.

All process functions are electrically-driven and controlled by automation to always perform on the optimal load level. All units are equipped with an integrated genset and a connection to an external electricity source. The OEM wear parts by Metso provide the unrivaled economy for each application need.

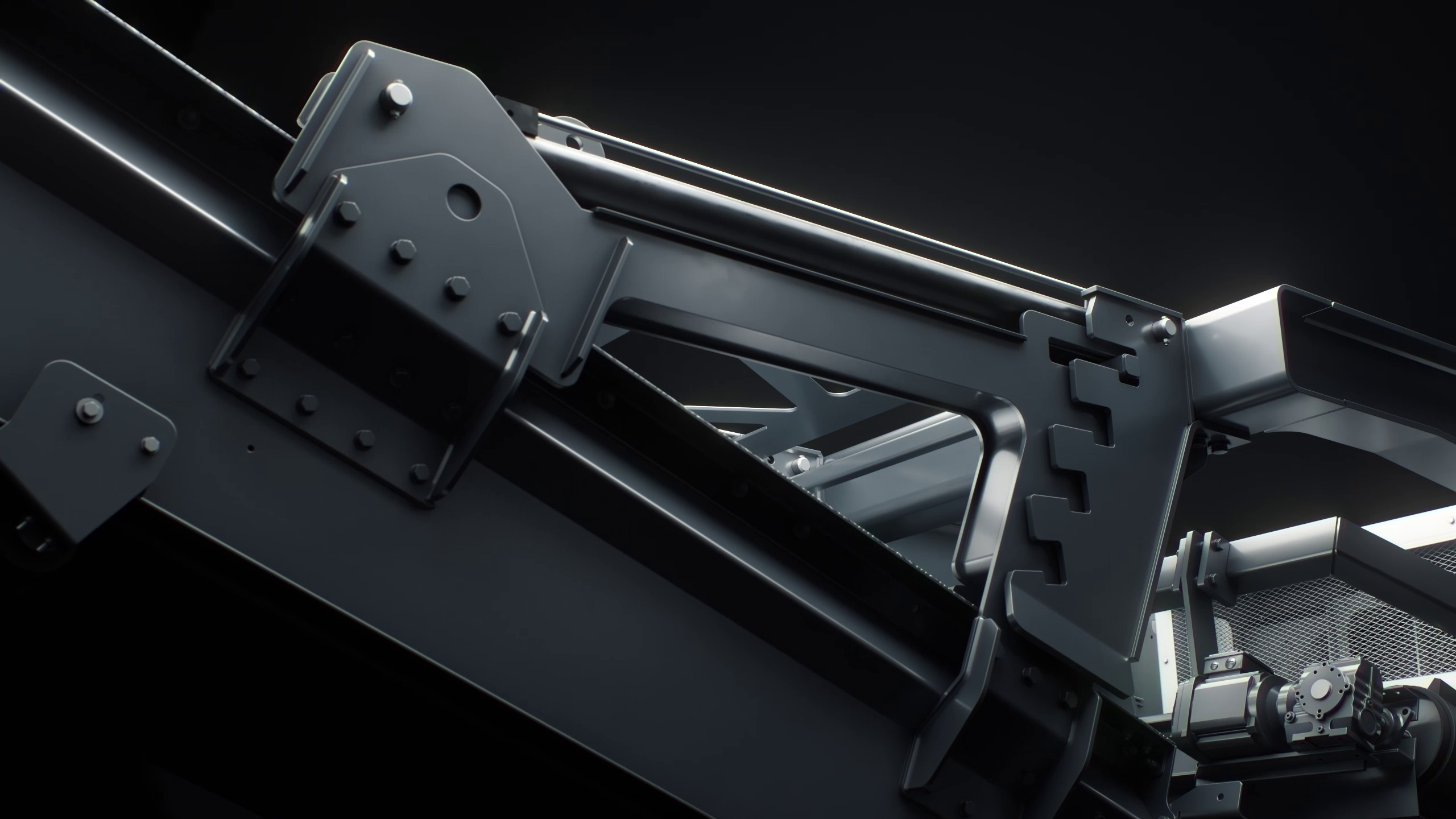

All major steel structures are designed to last at least 20 000 hours for maximum uptime, and only globally proven high-quality components are used.

All features are thoroughly tested to perform in demanding conditions with dust and vibrations. With robust digital controls, multiple Lokotrack units can be quickly set up for transport and operation.

Using the same design in all units makes maintenance actions easy-to learn and perform. With extensive lighting solutions, machines can be operated safely in all environments.

Hydraulic oil volume in the machines is reduced by 90% compared to the industry average. At the same time, the units can be operated independently for a longer time than before.

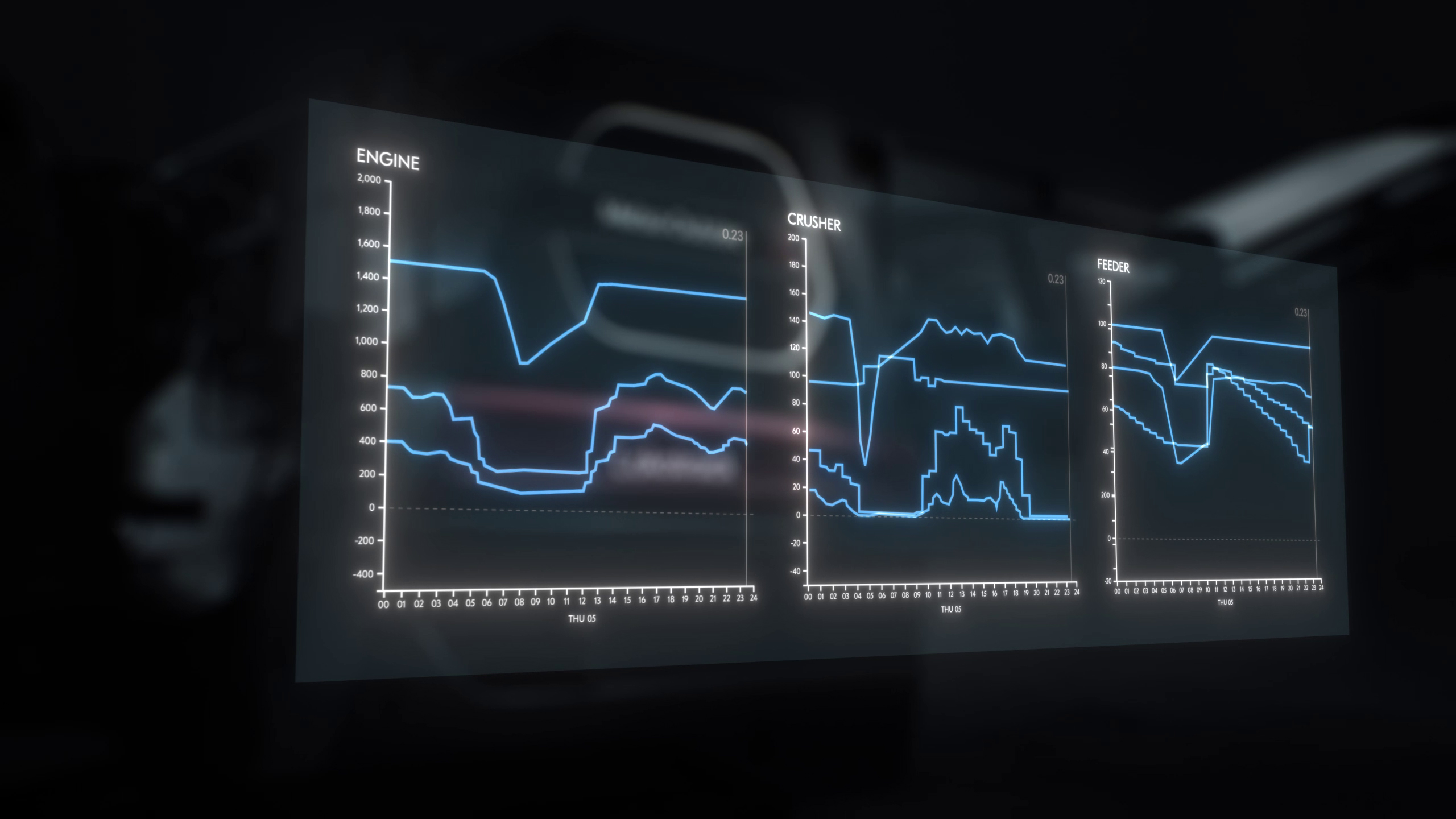

During operation, the complete process can be remotely controlled with cameras from an intuitive mobile interface. Advanced process control system with frequency converters helps to achieve the superior product throughput and quality from the latest crushing and screening technologies. The modular design enables upgradable solutions, smaller parts inventory and better uptime.

All units are equipped with a 24/7 remote monitoring solution, providing real-time performance insights and troubleshooting via any web-enabled device. Modular design allows greater parts compatibility across the portfolio, making servicing the units faster and adaptation to new process requirements and upgrades smoother.