The world is actively seeking better ways to work without harming the environment In the global steel industry around 70% of the yearly produced crude steel is still produced via the traditional blast furnace route. The fundamentals of this blast furnace route are based on (a) processing an iron bearing material/burden (like CO2) intense sinter and (b) burning a fossil carbon carrier (like coke) as an energy source. Both play a large role in a very challenging fight against global CO2 emissions within the steel industry.

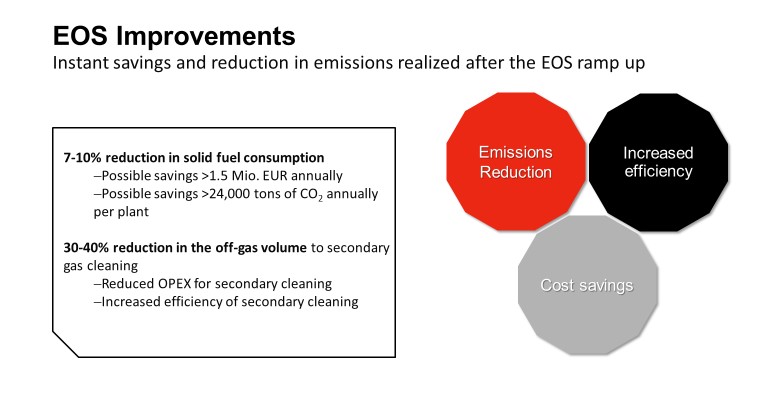

Metso has recently started operation of the first Emission Optimized Sintering process, a so-called EOS Sinter Plant, in India, supporting the “green sinter” movement from Metso. The clear focus of this sinter off-gas recirculation upgrade is emission reduction as well as energy efficiency increase. With this upgraded product, the sinter plant operatores achieve fossil fuel savings as well as substantially reduce the sinter off-gas. This reduces the total emissions of the sinter plant (not only CO2), whilst also providing significant savings in every day operational costs.