Try out the value calculator for dewatering of PCC

What is the value for your process?

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Silica Minerals represent the group of minerals composed of silicon and oxygen forming the chemical formula SiO2. Silica can occur in macrocrystalline, cryptocrystalline, and amorphous forms. Industry predominantly uses the crystalline form of silica, i.e. quartz. Silica is used as granular products containing the particle size range >63 µm. Fine-grained silica is used as functional fillers in various applications.

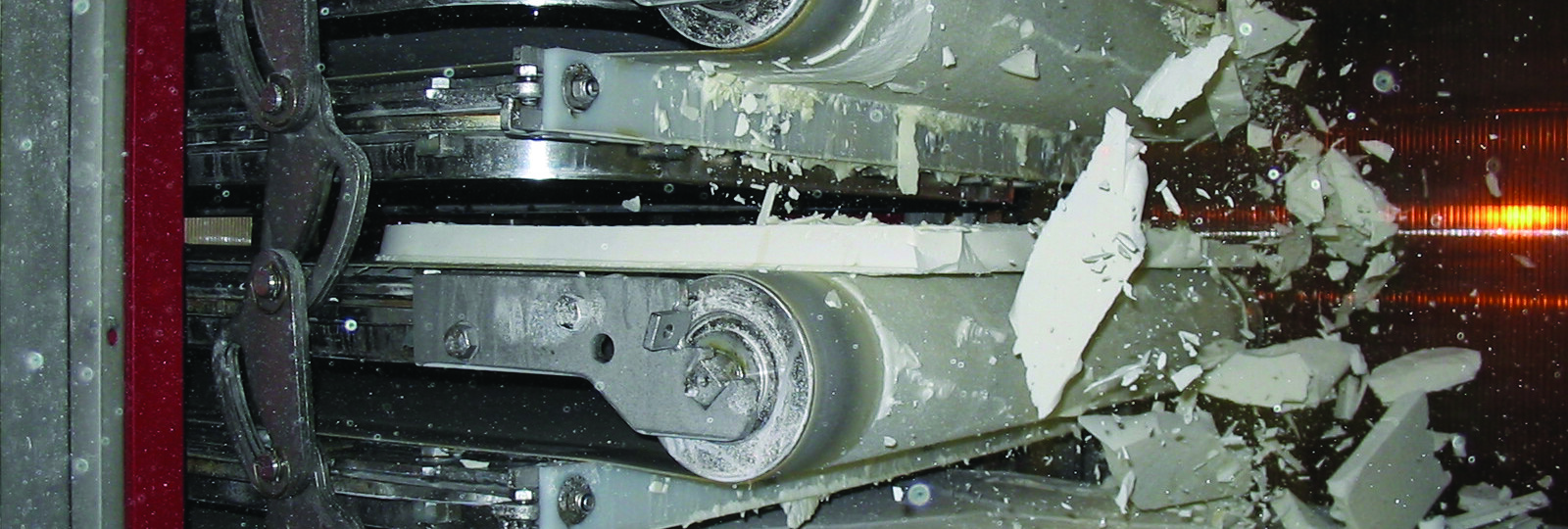

The production process for silica sand consists of crushing, grinding, sizing, beneficiation, dewatering, and drying. Metso can supply complete flowsheets using its own equipment and that of partners. Our Metso Plus portfolio helps reduce energy consumption and emissions, improves water efficiency, supports circularity and is designed to offer market leading safe operation.

Pressure filtration for precipitated calcium carbonate (PCC) processes

Compared to conventional filter presses, our pressure filters enable more effective pressing and drying leading to lower cake moisture. Dryer cake after filtration requires less thermal drying leading to improved product quality while helping to cut dryer energy consumption. Effective pressure filtration reduces product loss (PCC solids) to filtrate, which means more product is available for packaging.

We’ve delivered over 50 pressure filters to PCC producers around the world, helping them save energy, reduce costs, and improve yield. Our filters are easy to adapt to both old and new production lines and can be installed with minimal downtime.

If downloading does not start automatically, click the link below.