Over 45 years of experience in TiO2 filtration

Over 100 filters delivered for TiO2 filtration worldwide

The combined surface area of all installed units is over 4000 m2

Every day, our filters produce over 300 t/h DS TiO2 filter cake

Metso’s solutions: Larox PF and Tube press

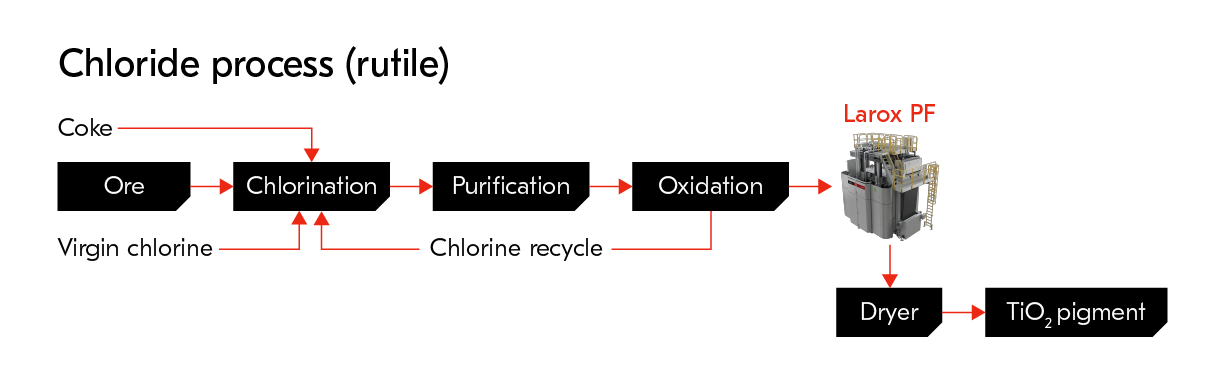

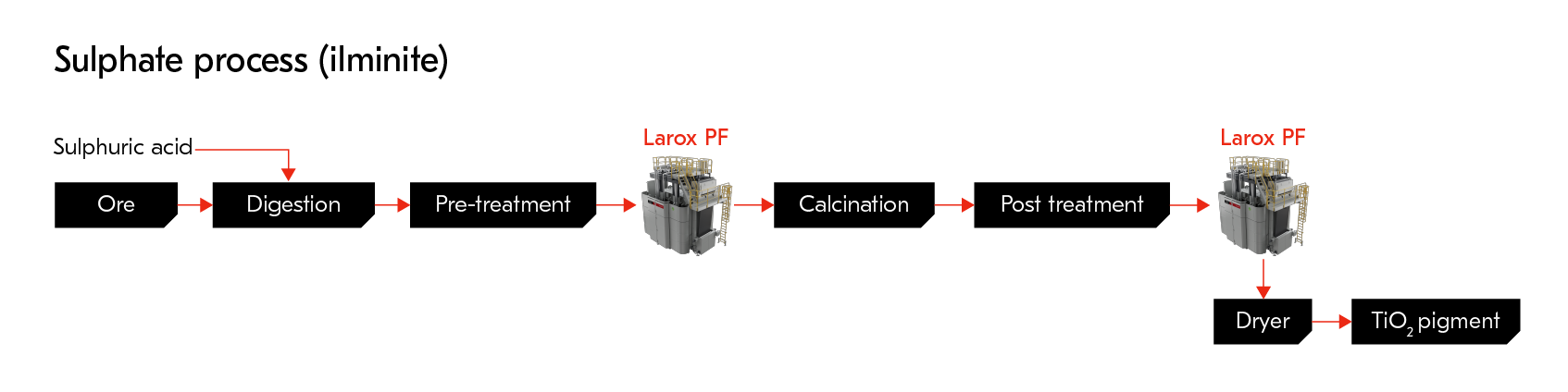

The primary dewatering mechanism for Titanium dioxide is pressure. Metso's solutions for dewatering of TiO2 are the Larox PF filter as well as the Tube press filter.

Larox® PF filters can achieve low residual filter cake moistures and high washing efficiency due to the horizontal cake formation.

Tube press filters can achieve the lowest possible residual moisture content for TiO2 filter cakes with the highest available pressing force.

Both, the Larox PF and Tube press filters provide lower and consistent residual filter cake moisture content compared to traditional filter presses, reducing the cost of drying after the filtration process. Metso has delivered over 100 pressure filters to TiO2 producers around the world, helping them save energy, reduce costs, and improve availability. Our filters are easy to adapt to both old and new production lines and can be installed with minimal downtime.

Benefits & applications

Achieve best filter cake wash efficiency and reduce residual moisture

Save energy, reduce wash water consumption, and increase plant capacity with Tube press and Larox® PF pressure filters for TiO2 dewatering and washing. Metso pressure filters and Life Cycle Services for calciner feed and finished pigment in industrial applications are based on our decades of experience and proven track record.

Our filters ensure a timely return on investment. They are easy to adapt to both old and new production lines and can be installed with minimal downtime.

In addition to their higher production capacity, our filters have lower running costs compared to conventional filter presses due to their lower energy & water consumption and minimize waste. The fully automatic operation ensures consistent performance while requiring minimal operator attendance.

Solutions highlights

Effective filter cake washing with Larox PF filter due to horizontal cake formation

- Better process control resulting in consistent quality

- No manual labor needed

- High availability due to fully automatic operation

- Lower moisture in filter cake leads to reduced dryer cost

- Process can run 24/7 without the need for regular cloth changes

- Highest dewatering pressures up to 100 bar

- Lower moisture in filter cake helps cut dryer energy consumption

- Horizontal chamber pressure filtration provides more efficient filter cake washing, reducing the filter cake washing ratio while decreasing salt content

Automatic pressure filtration with various cloth options results in exceptionally clear filtrate

- Efficient filter cake washing improves pigment quality

- Dryer filter cake requires less thermal drying after filtration leading to improved product quality

- Fully automatic operation results in a more consistent product

Value calculator