More than 60 years of experience

200+ references worldwide, totaling over 4600 m2 filtration area

Several production lines use a combination of Larox® filters leveraging benefits of the different technologies

Metso filters produce various pharmaceutical products everyday

Advanced filtration solutions for the pharmaceutical industry

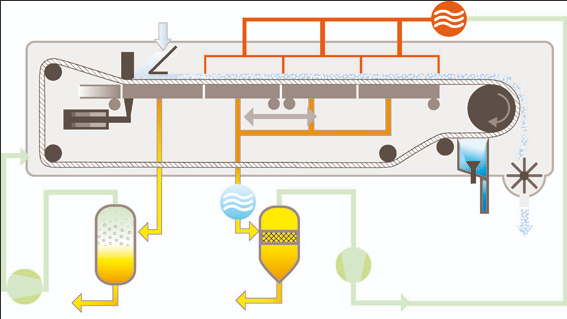

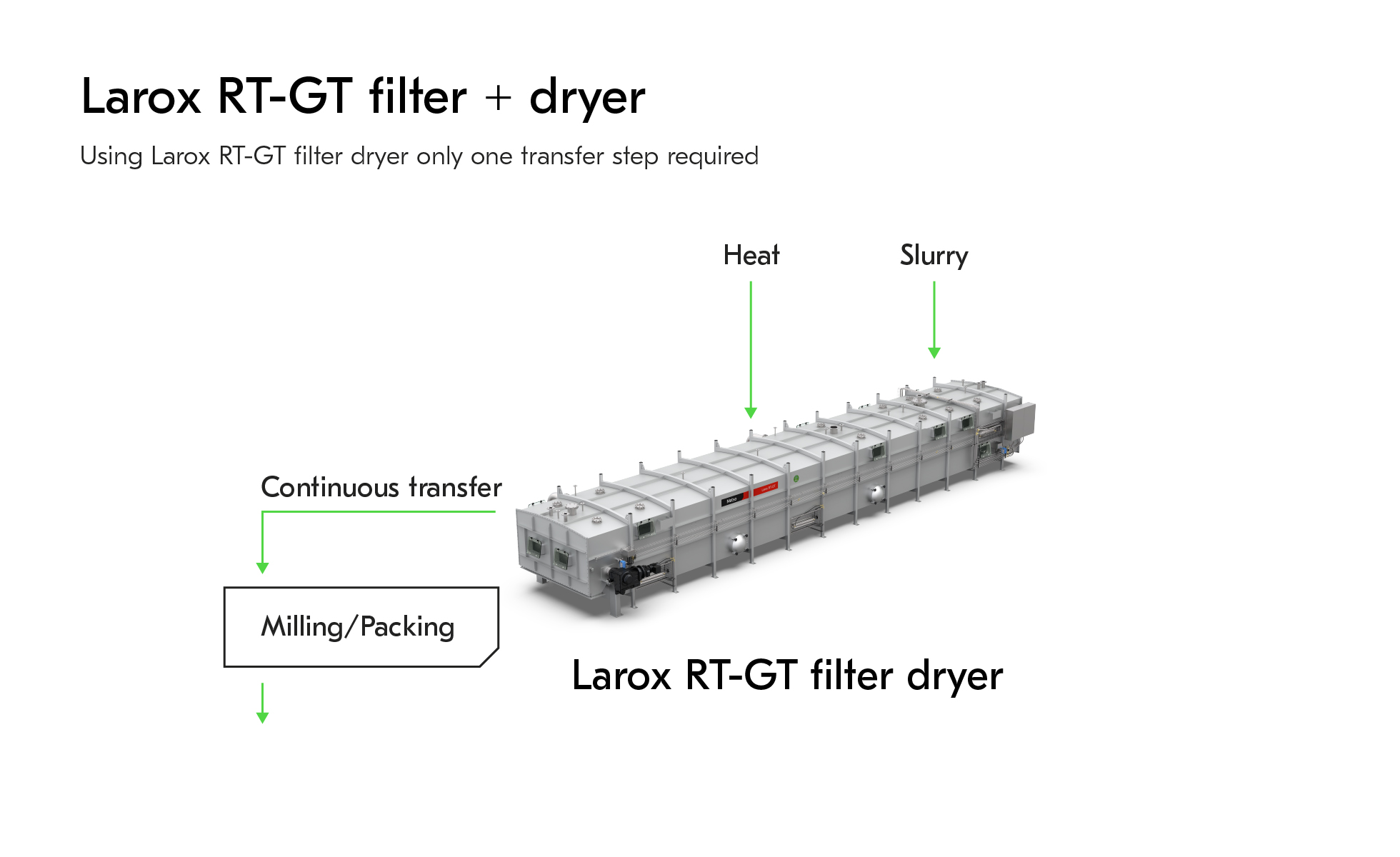

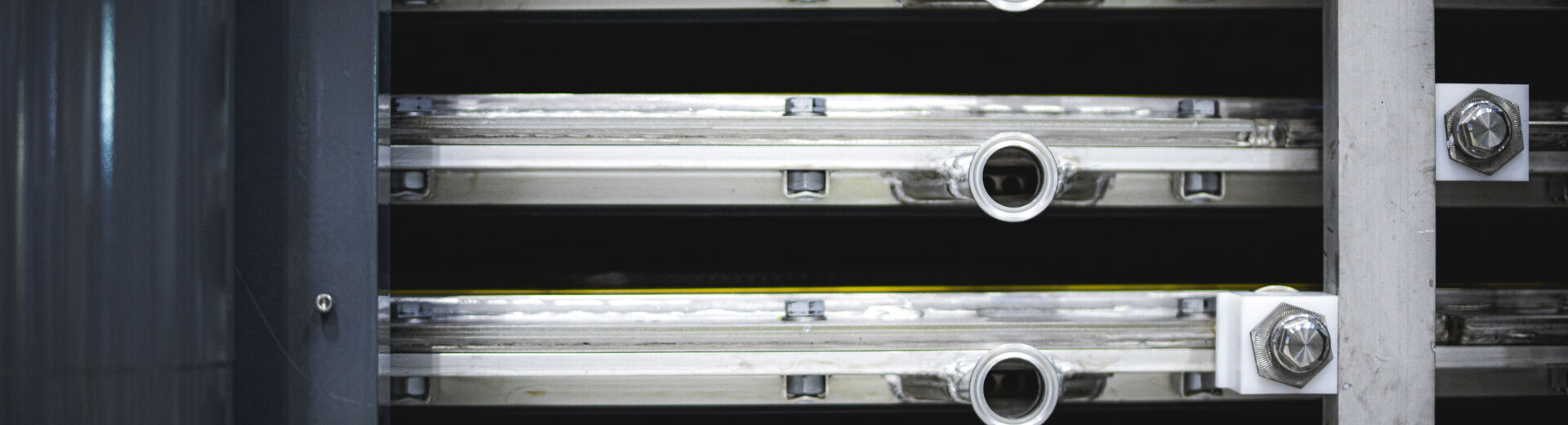

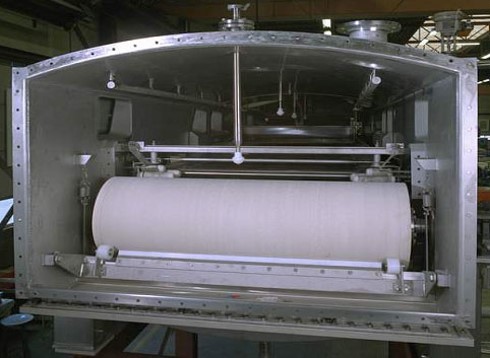

Metso’s solutions for pharmaceutical filtration include the Larox® RT-GT, Larox® PF, Larox® PF-DS filters. Larox® RT-GT filters offer fully sealed housing (Gas Tight) isolating the process area tighly either for product safety or with inert atmosphere for solvent based processes. The Larox® RT-GT filter can combine mutiple process steps in one single unit including; separation, efficient cake washing and even hot gas drying. Larox® PF and Larox® PF-DS filters achieve low residual cake moistures and high cake washing efficiency due to the horizontal cake formation.

- Larox® RT-GT filter is designed to have all maintenance components outside the housing, resulting that the housing has to be opened as infrequently as possible.

- Larox® PF and PF-DS filters operate fully automatic, minimizing operator attendance, while at the same time maximizing the availability. The automatic batch operation significantly improves end product quality and reduce final drying cost when compared to centrifuges and traditional filter presses.

- We’ve delivered 190 filters to Pharma producers around the world, helping them save energy, reduce costs, reach required GMP (Good Manufacturing Practice) and FDA (Food and Drug Administration, US authorities) requirements and improve availability. Our filters are easy to adapt to both old and new production lines and can be installed with minimal downtime.

Benefits

- Ensure high-quality and uniform washing with our fully automated process control and continuous optimization

- Run 24/7 without the need for regular cloth changes

- CIP (clean-in-place) options available to comply with GMP requirements

- Multiple unit operations can be performed in 1 unit

- Ensure minimal solids loss in filtrate

- Reduce wash water consumption

- High consistency of process liquids to minimize further processing needs

- Significantly increase dryer capacity with lowest possible moisture in filter cake

- Get 24-hour support from our global service network

Typical applications

Experience with different solvents

Main benefits per filtration solution

- Superior cake washing

- Multiple cake washing options, including counter current, different liquids, etc.

- Full cake discharge, even for difficult cakes

- Continuous cloth washing & cloth sanitation options

- Continuous operation giving consistent product quality

- Fully enclosed

- Solvent processing with nitrogen blanketing

- ATEX certified

- GMP, FDA certification option

- CIP cleaning option

- Excellent cake washing

- Closed processing area, only opened for solids discharge

- Cake discharge scrapers

- Automatic cloth washing & cloth sanitation options

- Fully automated operation eliminating operator impact

- Option for ATEX certification of the main filter

- GMP options

- FDA certification option

- CIP cleaning option

- Superior cake washing

- Multiple cake washing options

- Full cake discharge, even for difficult cakes

- Automatic cloth washing & cloth sanitation options

- Fully automated operation eliminating operator impact

- Closed processing area, only opened for solids discharge

- Option for ATEX certification of the main filter

- GMP options

- FDA certification option

- CIP cleaning option

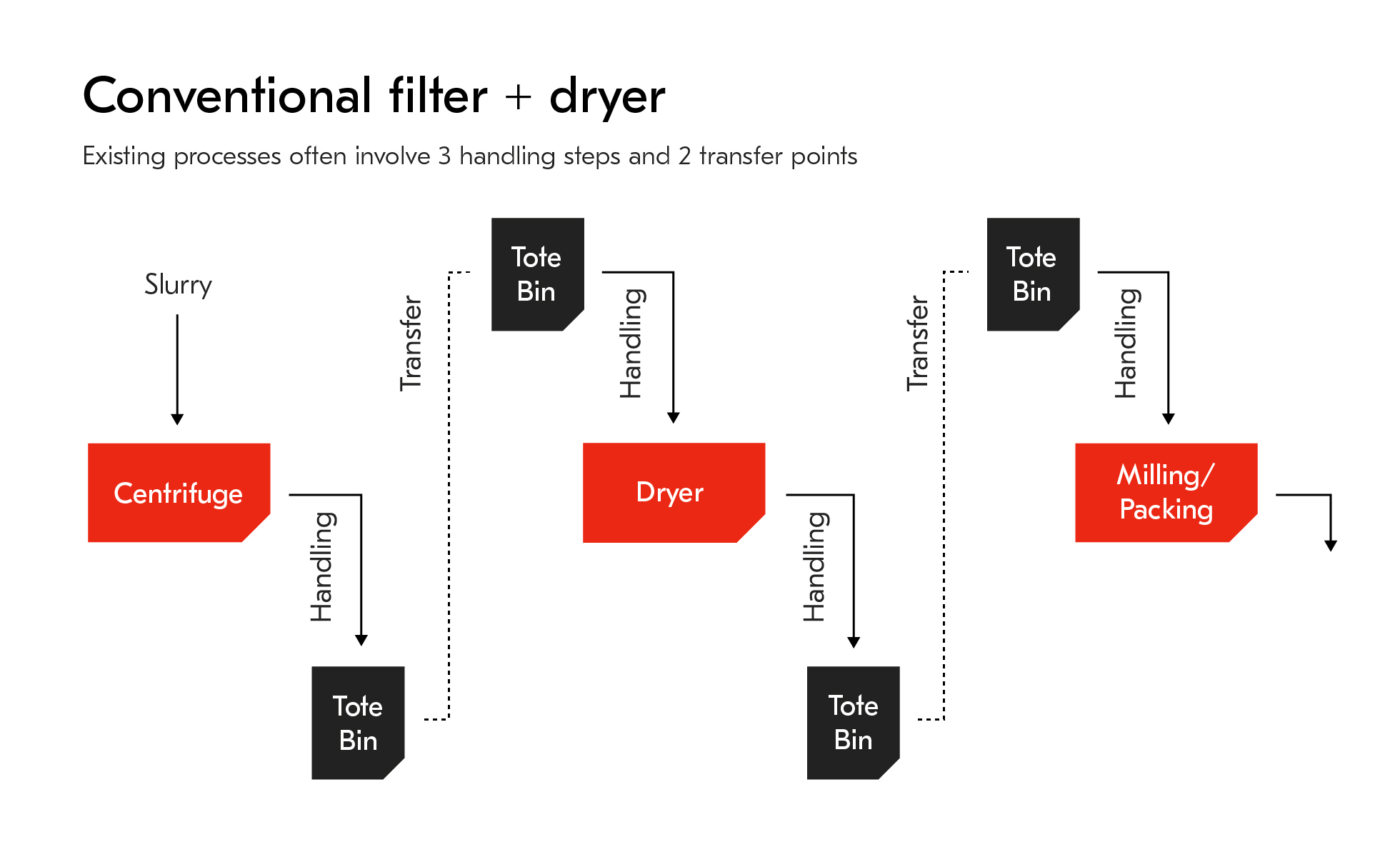

Process