Try out the value calculator for dewatering of PCC

What is the value for your process?

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Over 35 years of starch dewatering experience

Delivered over 60 pressure filters to PCC plants worldwide

The combined surface area of all installed units is over 1750 m2

Each day, our filters produce 200 t/h DS of PCC cake

If downloading does not start automatically, click the link below.

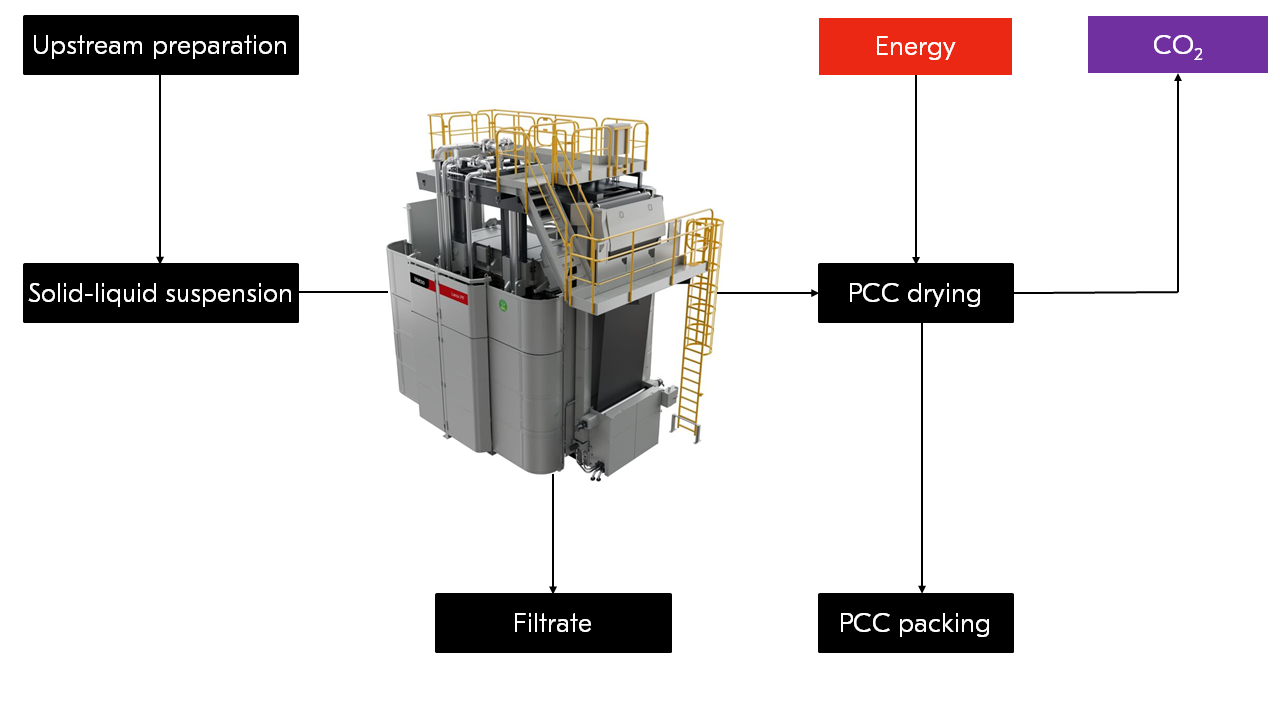

Compared to conventional filter presses, our pressure filters enable more effective pressing and drying leading to lower cake moisture. Dryer cake after filtration requires less thermal drying leading to improved product quality while helping to cut dryer energy consumption. Effective pressure filtration reduces product loss (PCC solids) to filtrate, which means more product is available to packaging.

We’ve delivered over 50 pressure filters to PCC producers around the world, helping them save energy, reduce costs, and improve yield. Our filters are easy to adapt to both old and new production lines and can be installed with minimal downtime.

The Larox PF filter has transformed many industrial processes, for example in fine chemicals, pigments, modified starch, and pharmaceutical fermentation broth. The primary dewatering mechanism is pressure filtration, in which a pressing force of up to 16 bar can be used. The unique manner in which the cake is formed and subsequently sustained means that other operations, such as drying, are as efficient and effective as possible.

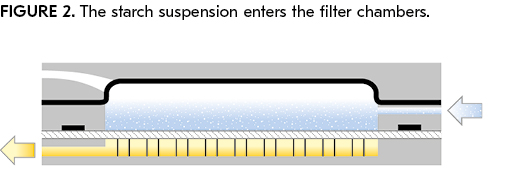

When the plate pack is closed, a set of chambers is formed and PCC suspension enters these through feeding pipes. A filter cake builds up and filtrate passes through the filter cloth, support grid, and filtrate hoses.

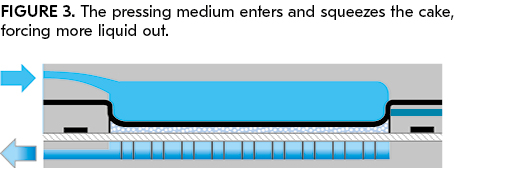

The pressing medium enters the space behind the diaphragm under high pressure. The diaphragm squeezes the cake, forcing more liquid out.

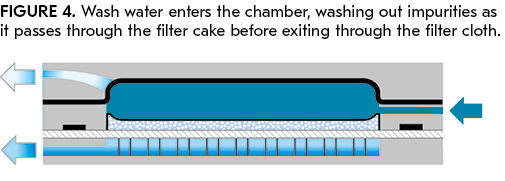

After the pressing pressure is relieved, wash water enters the chamber through the same feed pipe as the suspension, filling the filter chamber while forcing the pressing medium out from behind the diaphragm. The water then passes through the filter cake solids, washing out impurities before exiting the filter chamber through the filter cloth to the filtrate collection line.

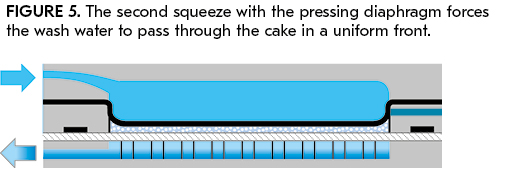

A second squeeze with the pressing diaphragm forces the wash water to pass through the cake in a uniform front. Because the cake is uniform and unstressed, this minimizes the presence of thin or thicker areas that may cause short-circuiting or bypassing. This ensures the best possible cake washing and the lowest possible water consumption.

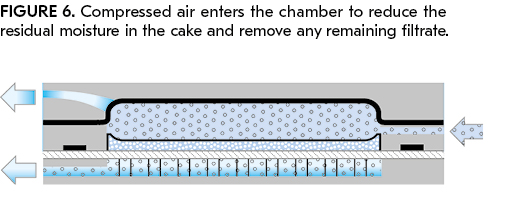

Compressed air enters the chamber through the feed port, pushes the diaphragm up, and passes through the cake in a uniform front in much the same way as the wash water. The airflow through the highly uniform cake reduces the residual moisture in the cake to the lowest possible level and also removes any remaining filtrate from the filtrate area.

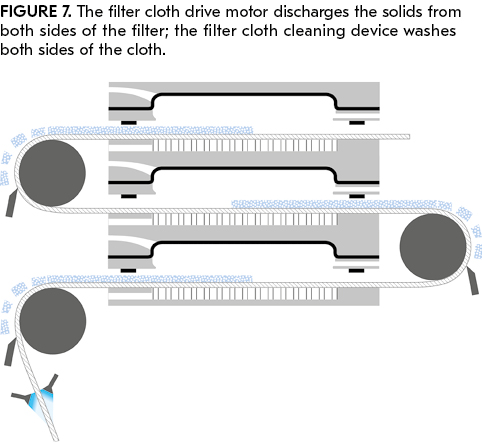

When the drying step is complete, all the filter chambers open up simultaneously. The filter cloth drive motor starts to move the endless filter cloth, discharging the solids from both sides of the filter. In this way, all of the PCC is passing forward through the process at all times, with no material hold-up.

At the same time, the filter cloth cleaning device washes both sides of the cloth in order to maintain a consistently high level of filtration efficiency and to remove any residual PCC.

Save energy and increase plant capacity with Larox PF pressure filters for PCC filtration. Larox PF pressure filters and life cycle services for carbonates are based on our decades of experience and proven track record.

Our filters ensure a timely return on investment. They are easy to adapt to both old and new production lines and can be installed with minimal downtime, meaning the initial investment is similar to that of a conventional filter.

In addition to their higher production capacity, our filters have lower running costs compared to conventional filter presses due to their lower energy, water, solid waste, and wastewater treatment needs.

Metso has experience in different types of PCC from aragonite, rhombohedral and stearate-coated carbonates to clustered aragonite, scalenohedral and prismatic carbonates.