Separating the best from the rest for more than four decades

The Metso Filtration Services team strives to deliver the best possible availability, performance, and quality whilst optimizing costs.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Over 35 years of starch dewatering experience

Delivered over 60 pressure filters to starch plants worldwide

The combined surface area of all installed units is over 2200 m2

Each day, our filters produce 400 t/h DS starch cake

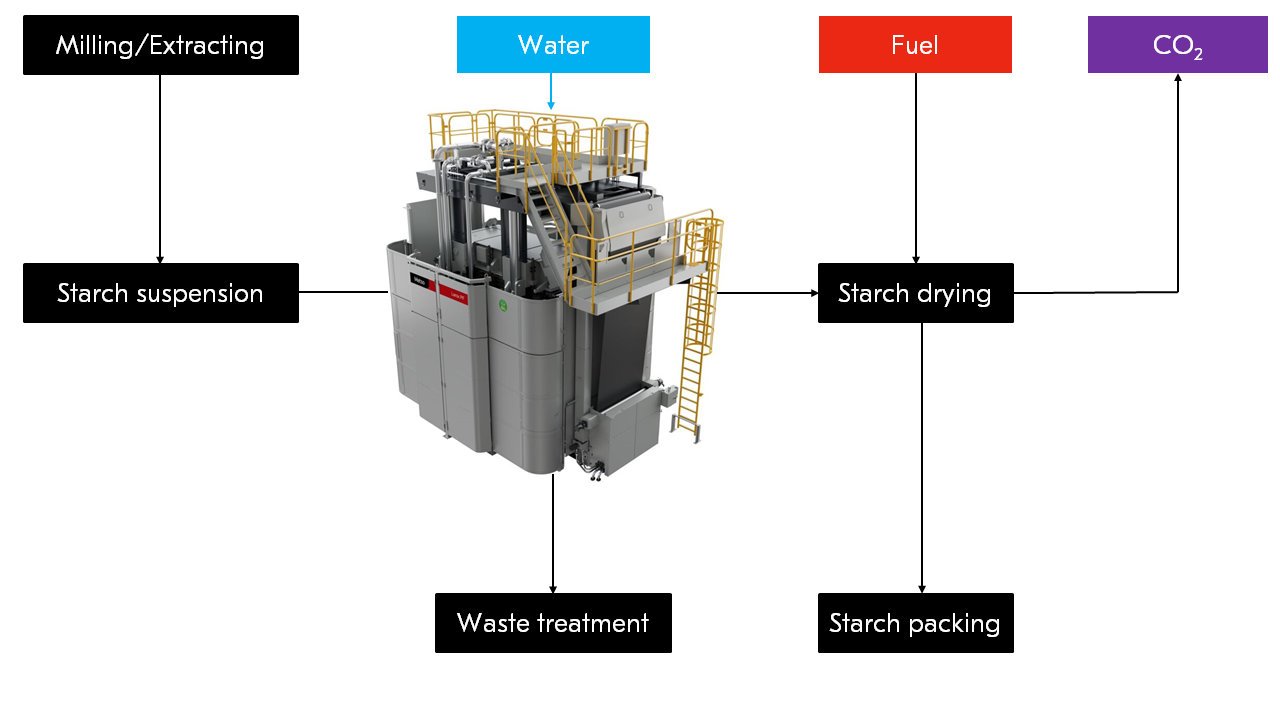

The primary dewatering mechanism is pressure filtration, in which a pressing force of up to 16 bar can be used. As a result, PF filters consume significantly less energy than centrifugal separators. Plant construction and machine maintenance are also simpler because there is no high-speed revolving mass and no continuously moving parts.

We’ve delivered over 60 pressure filters to starch producers around the world, helping them save energy, reduce costs, and improve yield. Our filters are easy to adapt to both old and new production lines and can be installed with minimal downtime.

Benefits

Applications

Washing and dewatering of native and modified starches such as:

If downloading does not start automatically, click the link below.

Save energy, reduce wash water consumption, and increase plant capacity with Larox® PF pressure filters for starch dewatering and washing. Larox PF pressure filters and life cycle services for native and modified starches in industrial food and pharmaceutical applications are based on our decades of experience and proven track record.

Our filters ensure a timely return on investment. They are easy to adapt to both old and new production lines and can be installed with minimal downtime, meaning the initial investment is similar to that of centrifuges.

In addition to their higher production capacity, our filters have lower running costs compared to centrifuges due to their lower energy, water, solid waste, and wastewater treatment needs. They are also easier to maintain as there is no high-speed revolving mass and no continuously moving parts.