It all starts with the right alloy

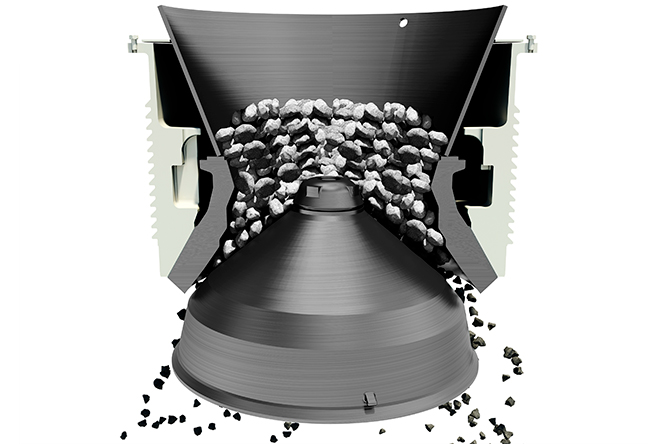

Let’s start with manganese alloys. The Metso XT710 alloy, containing around 18% manganese, has become the standard in the aggregates industry and works wonders for HP cones. However, it’s worth noting that XT710 is very commonly used in Nordberg C-Series™ jaw crushers and GP Series™ cone crushers as well. But what if you want an alloy that is more purposefully engineered just for HP cones and their kinematics?

The answer is the Metso XT720 alloy with increased manganese (~21%) and chrome. It’s a tailored alloy with up to 10% longer lifetime than the standard XT710 alloy for HP cones, so its cost-to-lifetime ratio is excellent. In this regard, I really feel like the HP cone crusher and XT720 alloy combination hits the sweet spot in most applications.

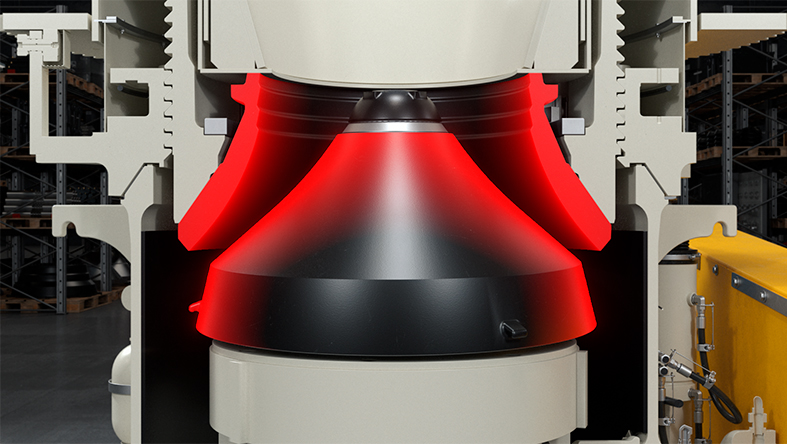

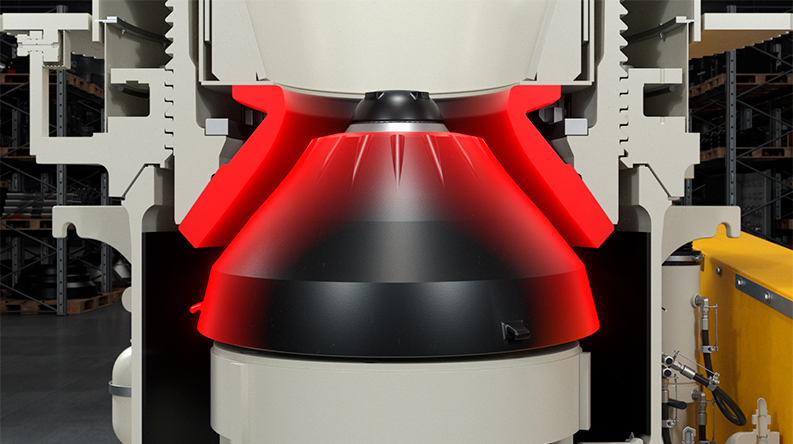

The XT720 alloy works especially well in HP cone crushers, mainly because of their uniquely long stroke length, high crushing forces and general chamber profile shapes matching the alloy and their properties perfectly. Again, this showcases how Metso is leveraging our crusher engineering and manufacturing knowledge also in the aftermarket offering!