Unscheduled stoppages

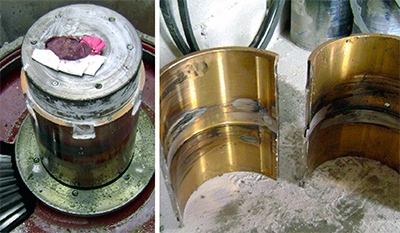

One possible failure is the burnout of the eccentric bushing. Generally, three conditions will indicate that there has been a bushing burnout:

- Total lockup of the crusher

- Overheating of the lubricating oil

- Bronze filings in the screen of the hydraulic unit

A few factors that can cause eccentric bushing burnout are:

- Use of improper lubricating oil

- A failure in the lubricating system (oil pump)

- Improper liner configuration

- Use of inferior quality liners

- Closed side setting (CSS) too small

- Off-center or segregated feed

- Excess fines in feed material

- Incorrect rotation

What should be done when a bushing burnout occurs?

First, it is necessary to identify the main cause of the failure to know which actions can be taken to avoid the same problem in the future. Then the damaged bushing must be removed immediately so that a new one can be installed.

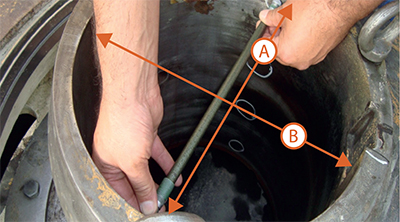

A few precautions should be taken: when the bushing becomes ‘seized’ (stuck) to the main shaft of the equipment (see picture below), it must be cut for removal.