Having certain materials available at the processing plant can minimize equipment downtime when replacing the wear liners. These materials include:

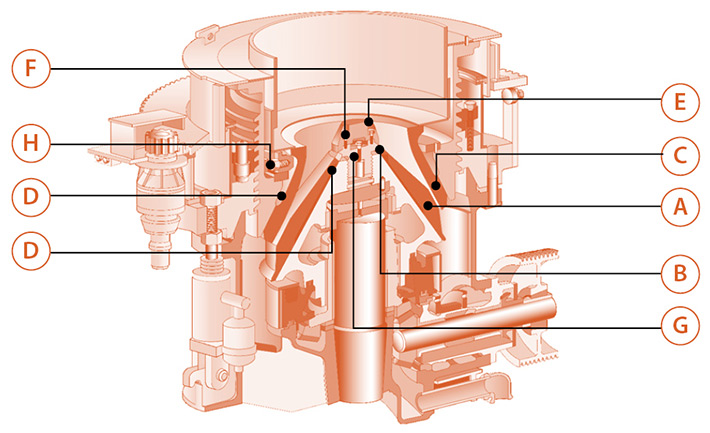

A) Mantle - also known as head liner.

B) Cutting ring - the cutting ring is not reusable, so a new ring should be installed every time the mantle is replaced.

C) Bowl liner

D) Padding material - its purpose is to cushion (shock absorption), not to fasten the liners. Lubrication of the head/bowl is recommended to facilitate subsequent replacement.

E) Cone feed plate - also known as the feed cone; it should be replaced every time the mantle is replaced.

F) Hex (hexagonal) head bolt - replace only if necessary.

G) Mantle locking bolt - replacement of this bolt is not necessary with every replacement of the mantle, but a new locking bolt should be kept on hand at the worksite just in case it needs to be replaced.

H) Set of square-head bolts - replacement of this/these bolt(s) is not necessary with every replacement of lining materials, but it is important to always have a set available at the worksite.