Legislation driving change

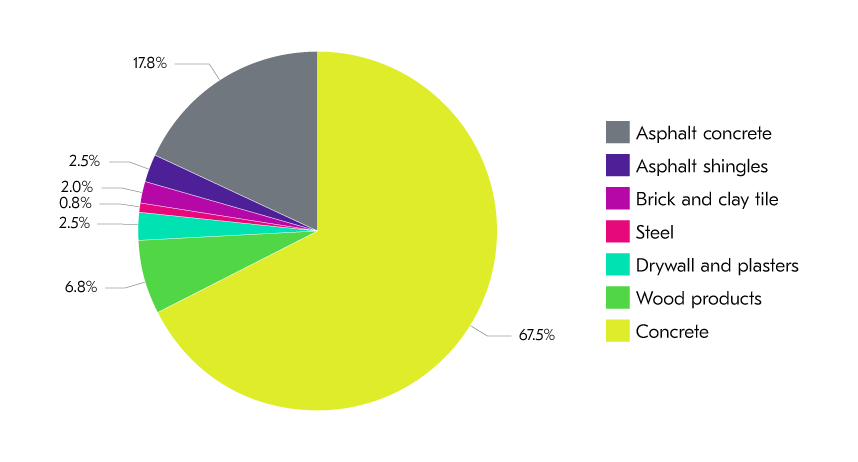

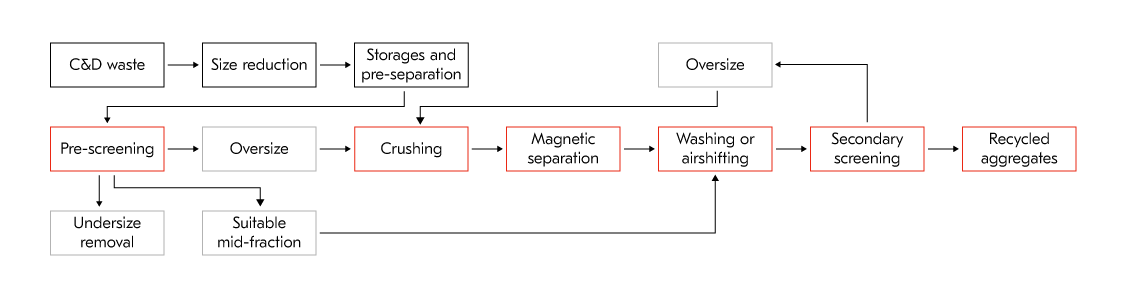

Regulations around the world are pushing for more recycling of construction waste. For example, the EU has had a law since 2008 requiring 70% of non-hazardous C&D waste to be recycled, recovered, or reused by 2020. At the first glance, this might feel like a challenging target, but separating materials like bricks, concrete, and iron can make recycling very effective. Once separated, concrete and bricks can be crushed and reused.

Recycling not only has positive effects on the environment, but it can also lead to cost savings. Recycled aggregates can be sold or reused, minimizing the need to buy new materials. Metso's practice shows that separating stones from recycled concrete can be cost-effective, lowering equipment usage and transportation costs.

Metso's equipment for efficient recycling

Metso's equipment, like track-mounted crushers and screens, or stationary jaw crushers and screens, can help make recycling more efficient. These machines are known for their versatility and are designed to handle multiple types of feeds. They also come with features such as dust and noise control, feeding arrangements, and optional equipment.