Two ways to reduce pegging - aperture size matters!

1. Smaller aperture size (typically less than 30 x 30 mm).

In the case of smaller openings, factors such as screen settings and conditions, level of flexibility and cloth design should be taken into consideration. The thickness and stiffness of a traditional, or woven, wire cloth can cause rocks to peg in the cloth. The wires in a self-cleaning wire cloth are not interlocked, so they are able to flex between each other, which results in less pegging. Therefore, choosing the right mesh for a screen, changing the screen cloth design, using smaller apertures, having blank areas , and using more flexible media options may all be options which can prevent pegging. A blank area is a part of a screening media without apertures.

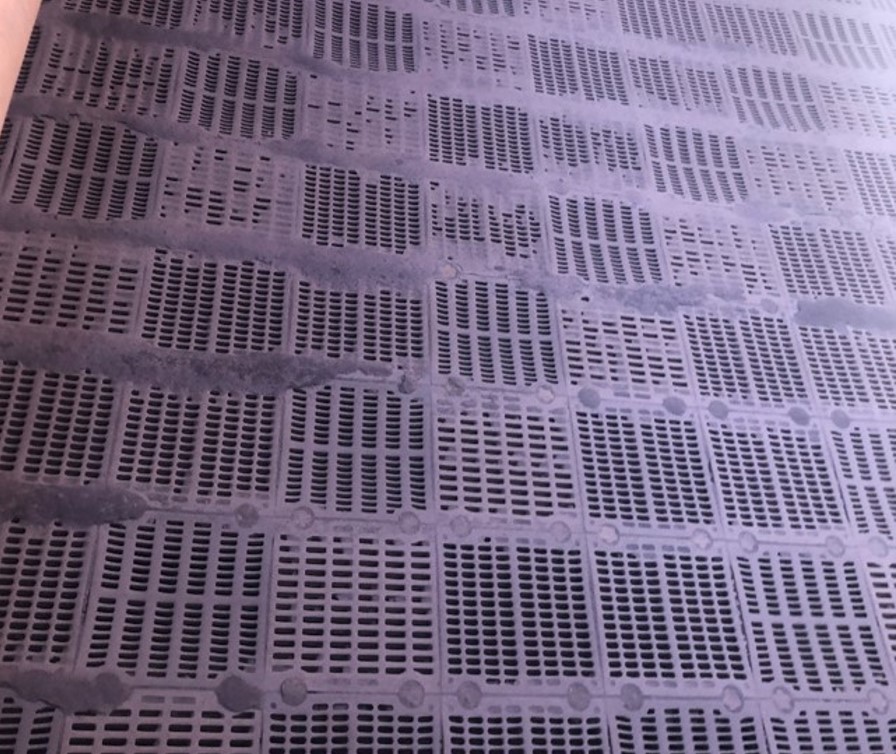

Image 2 below showcases wire cloth to the left compared to rubber tension mat to the right. It is evident that pegging occurs more in the wire cloth. The main reason for this is that wire cloth is a less flexible screening media compared to rubber cloth. The rubber cloth also has the advantage of blank areas above the supports which prevents pegging between the hole and support on the rubber cloth.

2. Larger aperture size (typically bigger than 30 x 30 mm).

With larger openings, crossbeams, ledge angles and other mechanical parts are factors to consider to prevent pegging. Making sure that the cloth opening is not interfering with the screen cross beams or similar is important.

One way of addressing this is to introduce blank areas in the screening media on top of the cross beams and also to modify the aperture patterns to avoid exposing parts of the screen.