We indicate some issues that directly affect the lifetime of the belt. To eliminate those, constant inspections are necessary to maintain the belt in a good operational condition.

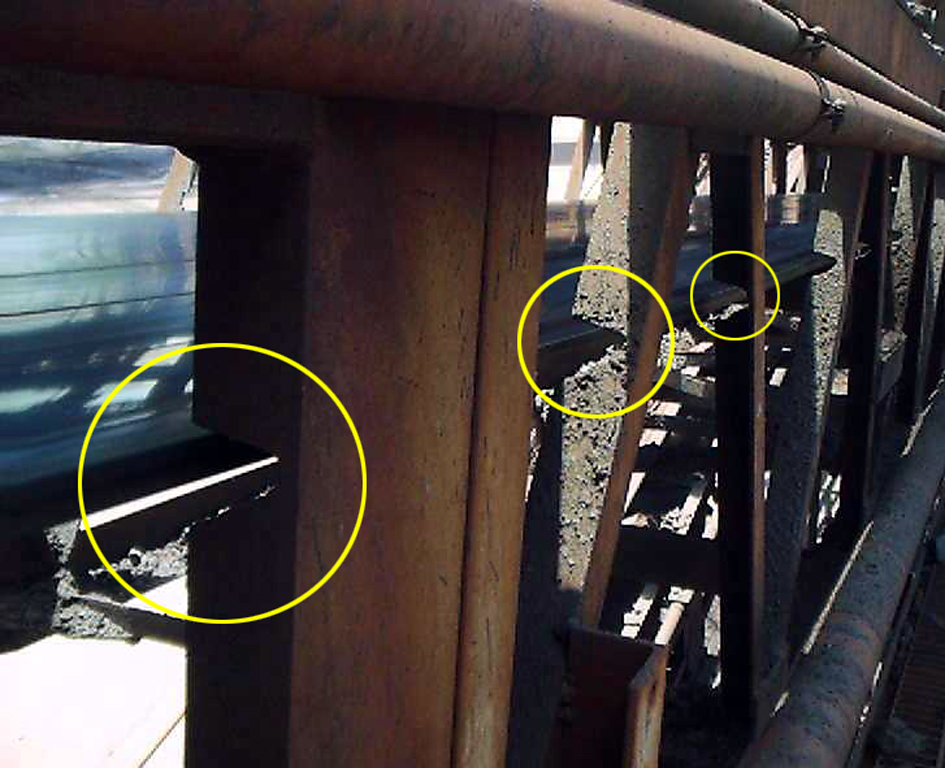

1. Metallic Structure

Check the alignment and leveling of the structure, both lengthwise and crosswise. This verification can be easily made by stretching a line/string along the structure and analyzing the deviations.

A bad aligned conveyor can touch the steel structure and therefore get seriously damaged

2. Pulleys

- For a good belt alignment it is very important to have the pulleys perpendicular to the centerline of the conveyor and parallel between themselves.

- Keep the drums clean, because the trapped materrial can cause irregular wear and belt misalignment.

3. Rolls

Same as for the pulleys, the rolls should be perpendicular to the centerline of the conveyor, clean and spinning freely. Jammed rolls, spinning with difficulty and/or slower than the others, cause irregular wear and belt misalignment.

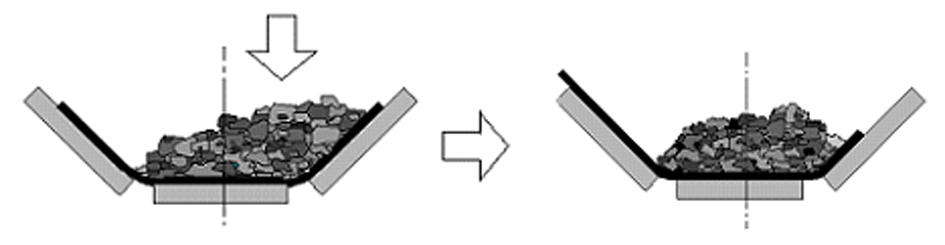

4. Feeding

Uncentered feeding is also one of the misalignment reasons. because due to the material being fed uncentered, there are forces that guide the belt to the side and keep it misaligned.

Decentralized feeding of a conveyor belt leads to misalignment of the belt and can decrease the lifetime of the belt.