1. Operational uptime and energy savings

The cornerstone of a successful mining operation lies in operational uptime and energy efficiency. However, measuring operational uptime isn't always easy. To accurately assess uptime, it's important to understand the operational and maintenance processes. Our approach is to seamlessly integrate technology with our engineering skills and knowledge. Besides constantly improving our digital solutions withing grinding plant, Metso also targets to opportunities and solutions in operation planning, maintenance, performance monitoring and energy-saving initiatives. We aim to maximize production while optimizing energy consumption, making your mining operation more sustainable.

2. Selecting the right technology

Choosing the right technology is a fundamental decision, especially when you're dealing with various equipment in a series. Conducting thorough testwork and benchmark comparisons are essential steps in the decision-making process. To determine the ideal technology for your operation, consider key process parameters such as particle size and ore characteristics. Matching these parameters with the right technology will help you achieve stable revenue and optimal process metrics.

3. Readiness of plant footprint

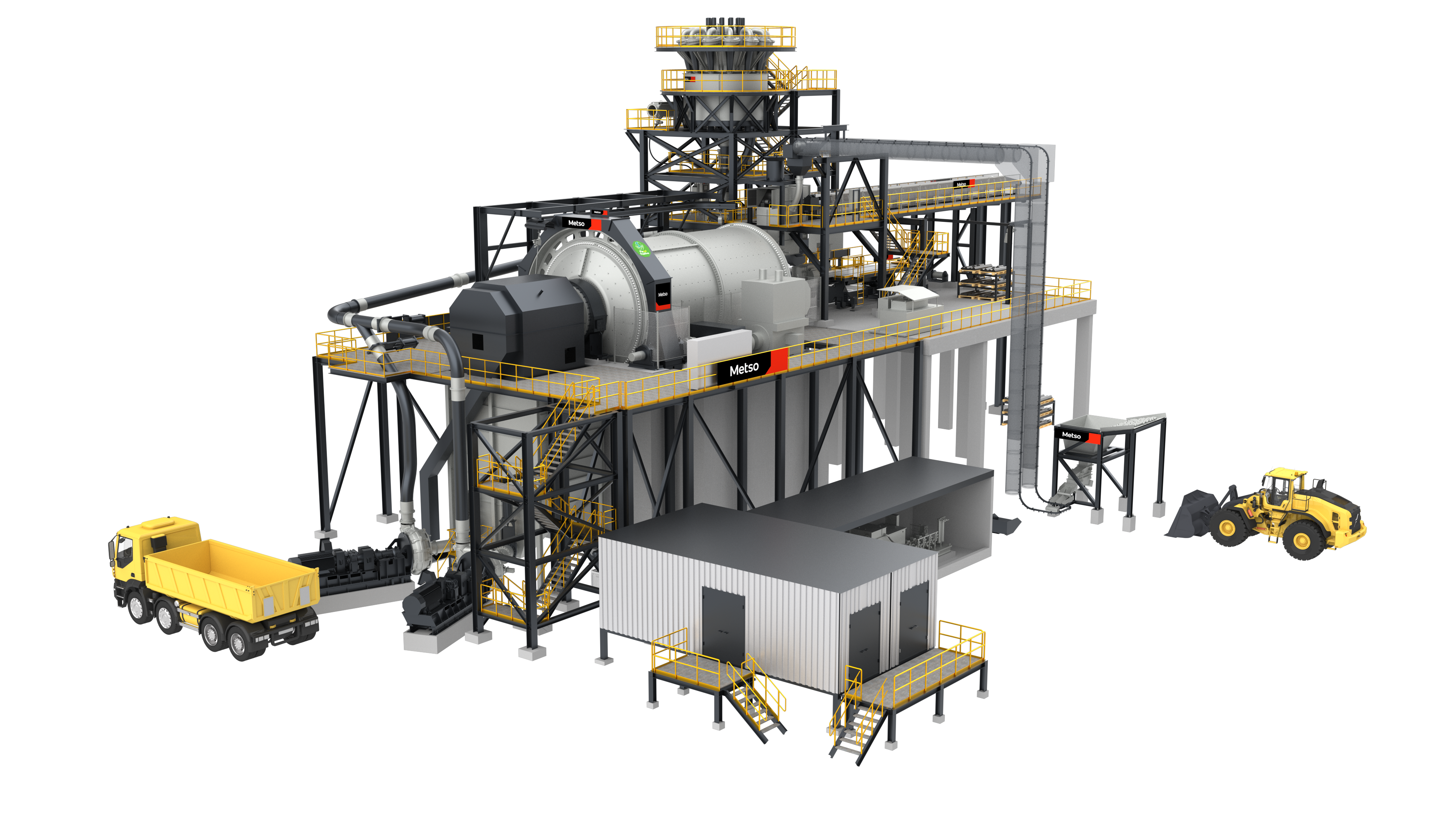

Creating a standardized grinding mill plant can be challenging due to site-specific conditions, safety requirements and operational criteria. To simplify the process, Metso structured the development of grinding mill plants into categorized and released applications. This approach allows to size and pre-engineer the plant based on particle size, various ore characteristics and tonnages. As you move from planning to the realized application stage, we aim to accelerate the traditional process design, equipment selection and footprint layout much faster with our 'ready to use' modules.

4. Performance guarantee - backed by testwork

When designing a grinding circuit, we focus on ensuring steady and productive operation. To achieve this, a performance guarantee is invaluable when offered along with a technical sounds flowsheet design. Despite the challenges in conducting testwork to conclude a representative ore body, the grinding plant can be designed to meet multiple process needs as the mining plan becomes progressively updated. Our solutions provide benchmark design parameters, but we also prioritize post-ramp-up optimization, considering the unique characteristics of plant and ore. Don't overlook the importance of post-ramp-up testwork to validate our initial assumption, as it's a vital step that many operators forget.

Efficient grinding with Metso's expertise

With our proven expertise, Metso Horizontal Mill Plant Units offer complete support in grinding circuit selection, as well as execution, service, and operation. Pre-engineered modules provide a unique edge in delivering rapid, safe and optimized solutions for grinding applications. Metso serves as a one-stop shop, from test work to flowsheet design; from equipment selection to execution and service support, all tailored to your project requirements. This greatly simplifies project management and implementation, ensuring a seamless transition to a highly efficient grinding circuit.

In summary, choosing the right grinding circuit for your mining operation is a complex but essential process. Metso is committed to helping you navigate this decision with a focus on operational uptime, technology selection, plant readiness and performance guarantees backed by testwork. By considering the four key factors, Metso can help you enhance your mining operation's productivity and sustainability.