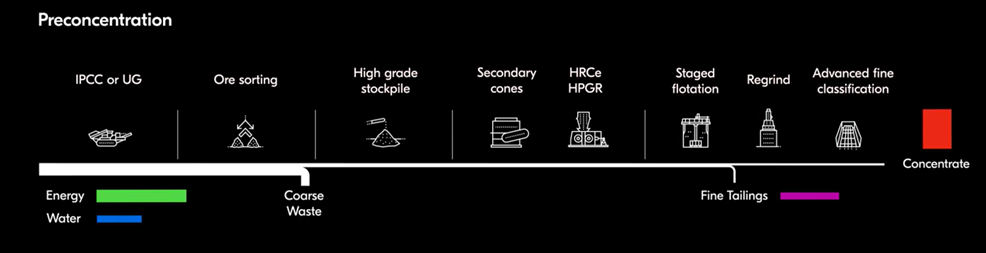

As high-grade ore deposits become scarcer, the mining industry faces the challenge of extracting lower-grade deposits. This means processing larger volumes per tonne of valuable minerals. Unfortunately, this shift comes with increased costs, energy consumption, water usage, transportation, processing and more.

So, what can we do about it?

Enter bulk ore sorting.

What benefits can bulk ore sorting bring to your operations?

-

Waste identification and separation

Ore sorting involves measuring properties in both valuable and waste material using various sensors. While sensor-based ore sorting isn’t particularly new, its application in the minerals industry has been limited to niche areas like industrial minerals, diamonds, and gemstones. However, our bulk ore sorting approach takes it to the next level.

How does it work?

-

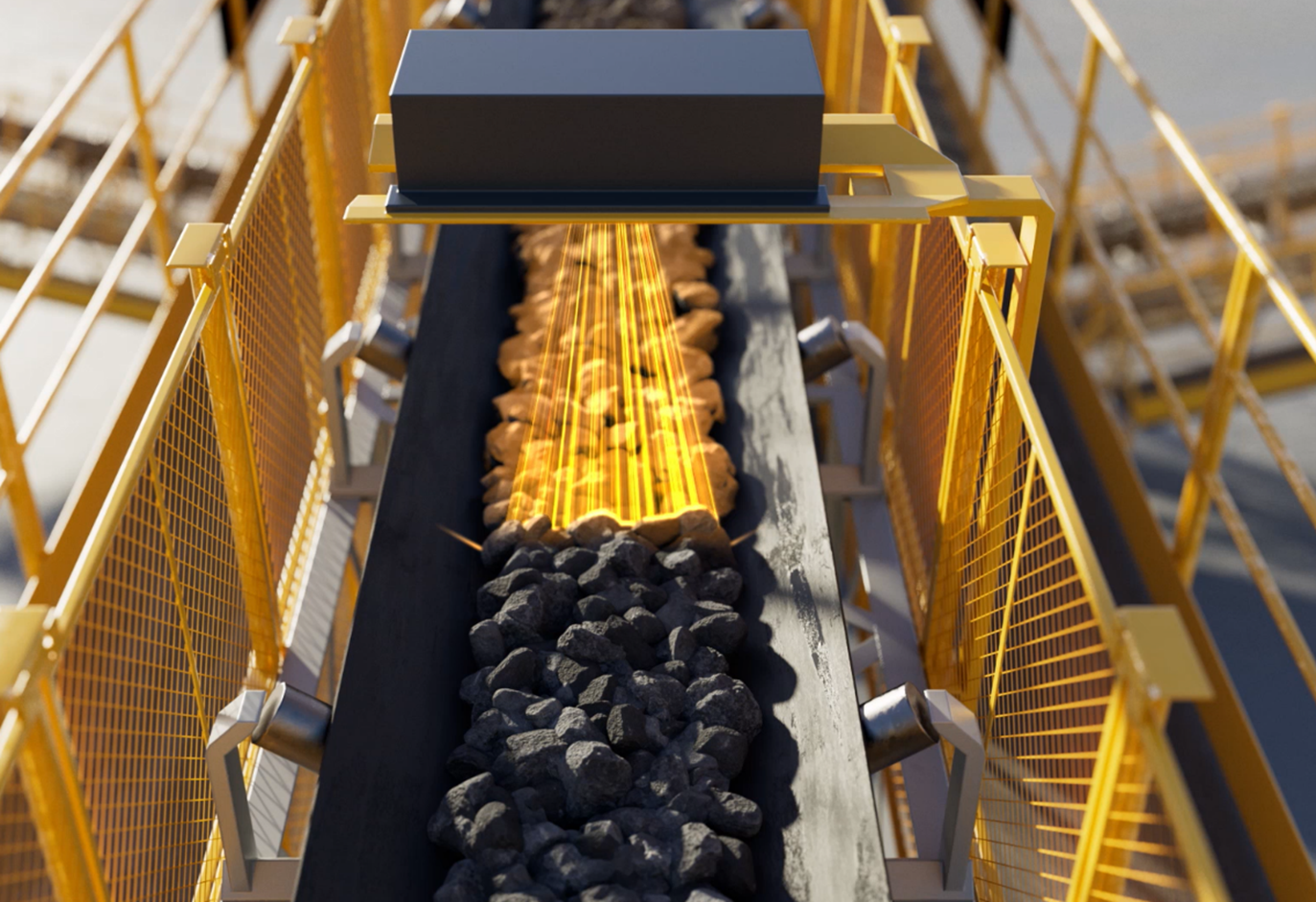

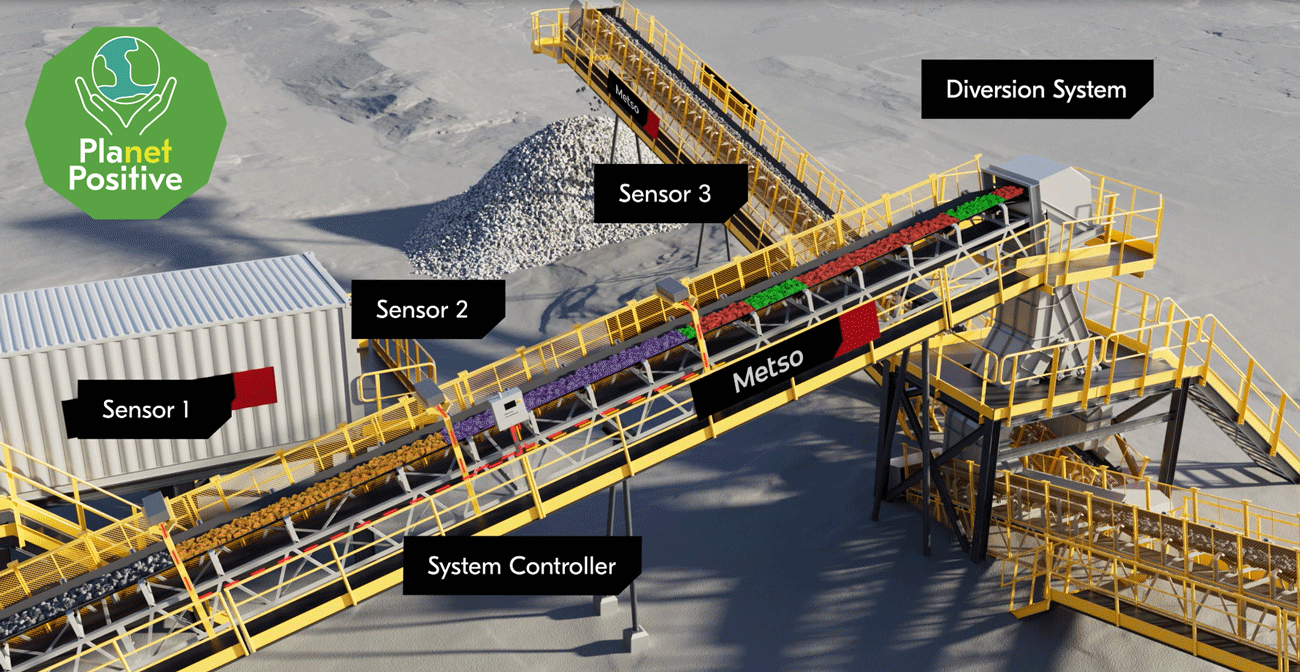

Multiple sensors are strategically placed along the processing line. This offers the potential of real-time analysis of material properties

-

The sensors analyze real-time data feeds from the material

-

A sensor fusion algorithm combines information from different sensors

-

Operators can customize sensor placement for optimal performance

For example, one high-speed sensor could measure color, another measures density, and the next measures something completely different like ore characteristics or the magnetic properties of the material itself. By combining these data points, you gain valuable insights. Is the material high in magnetite? Does it have a specific color? Based on this information, you can confidently decide whether it’s valuable and should be processed further. At the same time, you minimize waste - which proves to be a great advantage in the fight against depleting ore deposits.

Kevin Graney, Director of Ore Sorting, explains: “With the Metso approach, we want to leverage new computing techniques and use them to analyze multiple sensor data streams at the same time to get the most value. Whether the parameters are pre-programmed, or the system learns along the way, using these digital tools will give operators the ability to bring their sorting to the next level.”

“Having information on each component is incredibly important, as it gives customers extra insight, and thus, extra confidence, when deciding to process the material” says Jorn Rohleder, Manager of Ore Sorting Technology.