The go-ahead for construction of the pilot plant at Harjavalta was given in 1946 and the first experiments were undertaken in February 1947. The encouraging results led to the owner, at that time Outokumpu, initiating the design and construction of the flash smelting furnace. This small – yet nationally very important – metals producer was under pressure to decrease its dependency on electricity, since a third of the total grid capacity had been lost to Russia during the winter and continuation wars.

70 years of flash smelting - shaping the industry

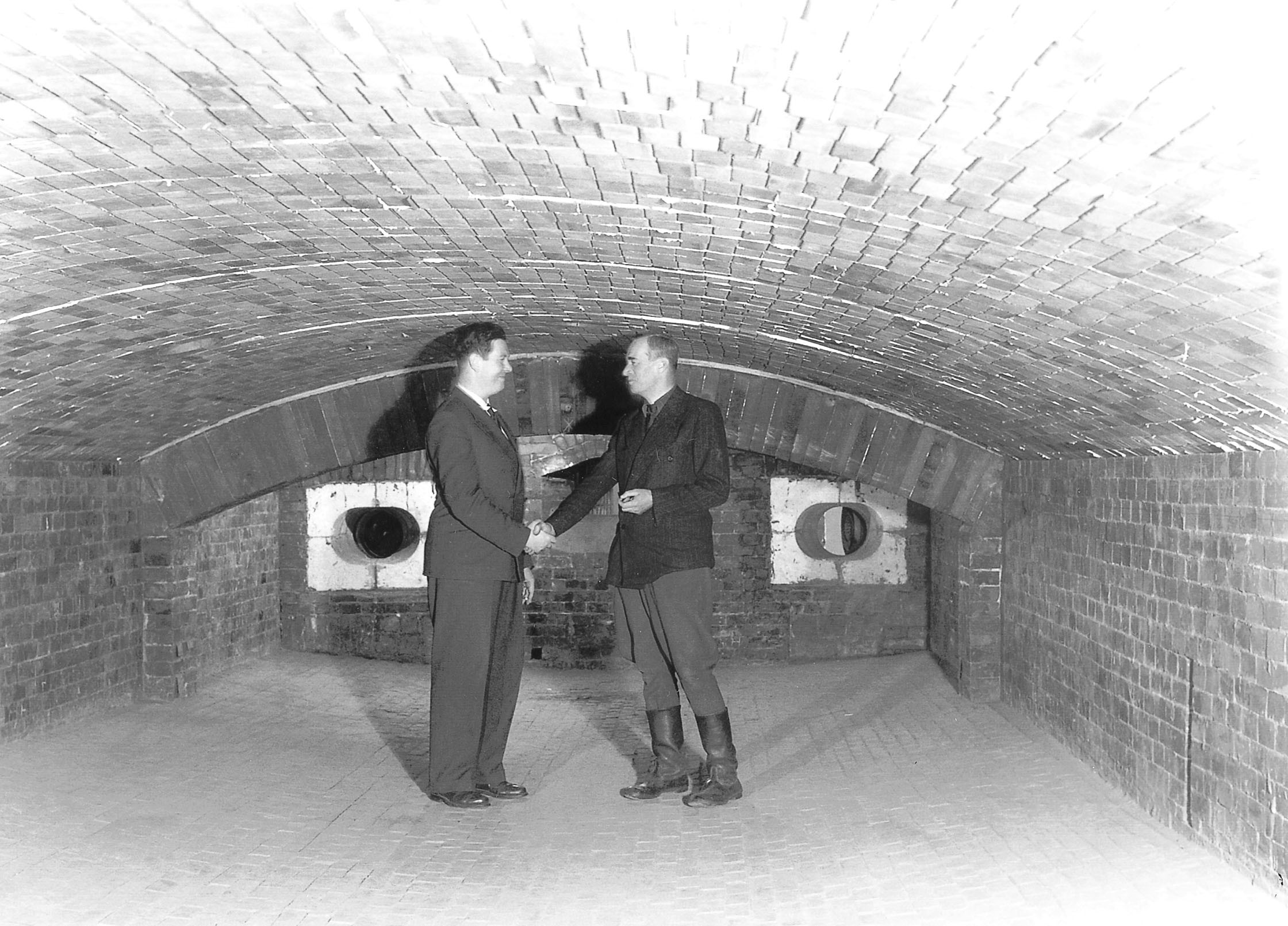

The first few years were laborious and difficult for the operating personnel, with calls to halt the trials and suspicions about the feasibility of the smelting method. The situation was worsened by two fatal accidents that occurred in the smelter, the first on April 25th 1949 just a week after start-up, which resulted in a two-week stoppage to enable safety improvements to be made.

The new process was a puzzle of equipment connected in a new way, and lots of changes had to be made to get the process to achieve its set targets. Although it took until the 1950s to resolve the start-up pains, the goal to decrease energy consumption was achieved. The total electricity consumption of the flash smelter line was about 1000 kWh per ton of anode copper, while the electrical smelter line was consuming approximately 3000 kWh to produce the same amount of anode copper.

The energy consumption of flash smelting has further decreased by approximately 20% since then due to the extensive development work that has taken place both at the Outotec Research Center in Pori, Finland and in cooperation with operators of the technology in many countries across the globe. The development path of flash smelting has seen various moves into different commodities such as its adoption for nickel production in 1959, for sulfur production from pyrite in 1962, and for production of lead from impure and pure concentrates in the 1966. The major developments have been the adoption of Direct to Blister in the 1970s and the development and application of continuous flash converting in cooperation with the Kennecott smelter during the 1980s and 1990s, at the same time as the Direct Outotec Nickel process was adopted for nickel. Recent decades have seen a greater focus on increasing safety, campaign time, and productivity through the development of furnaces and process equipment.

As the fathers of flash smelting explained in the opening words of the first International Flash Smelting Congress in 1972, necessity is the mother of invention. We now face a much larger necessity: the need to tackle global warming and pollution in general. In the same way that post-WWII energy and geopolitics affected how copper was produced, the need to tackle climate change and pollution will change the game again in terms of how we achieve reductive conditions in metallurgy and how well we manage to prevent metals and harmful elements from escaping the smelter and refinery. As always, we are motivated primarily by enthusiasm and curiosity to develop solutions that will enable the global smelting community to solve this challenge.

We want to acknowledge the work of all the brilliant and devoted people who have helped to develop flash smelting and its applications, from the great individuals who came up with the theory to the teams and international communities that helped make it a reality.