Advanced Process Control (APC) systems have been one of the most beneficial tools in past decades in the minerals processing industry in decreasing process variance and enabling operation closer to process boundaries. However, it is important to understand that the performance of these systems is highly dependent on getting reliable real-time information from the process, which is needed for good control actions.

In order to optimize grinding circuits, new analyzer systems for online 3D based particle size imaging and strain gauge based mill charge analysis have been developed. The introduction of these new systems has provided a more holistic view to the status and performance of the circuits and thus made it possible to implement more robust and beneficial APC strategies for stabilization and optimization.

Grinding circuit optimization with APC

Advanced process control (APC) and optimization systems have been one of the most beneficial tools in past decades in the minerals processing industry. APC has the capability to take into account multiple variables with time delays, interactions and constraints during multiple changes, typically to set-points of the regulatory level controllers. APC systems and applications run at the highest levels of control system hierarchy and typically utilize advanced calculations, delay compensators and estimators with rule and model based predictive and multivariable techniques. A well instrumented process, tuned base level controls, understanding of the process, mineralogy and constraints are absolute requirements for a successful implementation and benefits.

Typical APC objectives for a grinding circuit are:

- Maximize grinding capacity while keeping the particle size within optimal range

- Minimize disturbances and stabilize feed to downstream processing

- Increase the availability of the grinding circuit and equipment

- Optimize circulating loads

- Minimize energy and consumable usage

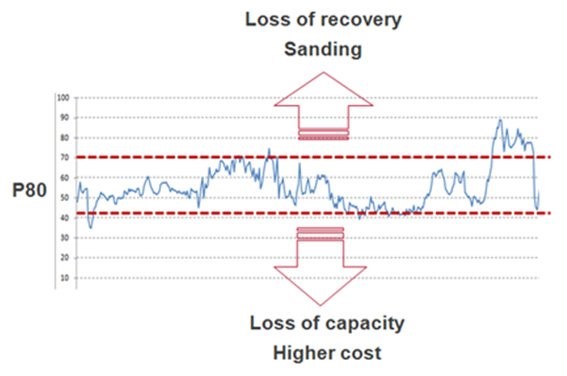

For many grinding APC strategies, particle size at the cyclone overflow is a critical feedback variable for determining the circuit's state and efficiency. For downstream processing, valuable minerals and metals recovery and the usage of the energy and reagents, are often highly dependent on the feed particle size distribution as shown in Figure 1.