But why after more than 100 years of Bayer process the derived residue and their respective storages are still being an issue? The first cause is economics, massive amount of residue without strong economically feasible use – alumina refinery residue exceeds 2.7 billion tons excluding the amount of rain water remaining in the dams worldwide. Easy and inexpensive storage methods were used in the beginning of the mining industry, when we lacked the knowledge of the environmental and economic impact of these solutions in the future.

In the recent years, environmental rules have been reinforced with compulsory registration, licensing for operations and penalty fees, and technologies have been developed to custom the necessities of this industry in a more economically viable form. Old dams are lasting, and finally, all the costs related to remediation after failures and the non-economically estimated loss of life of many are the drivers for moving from elderly technological paradigms to innovative and advanced technical solutions.

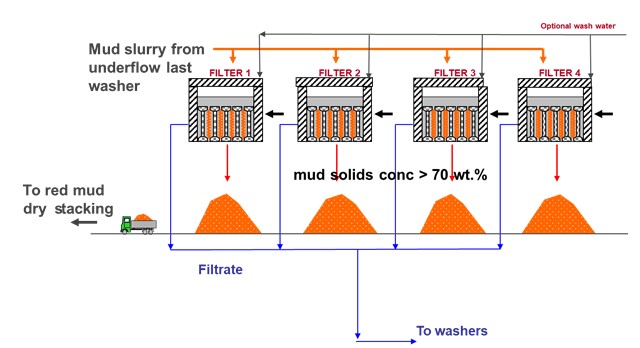

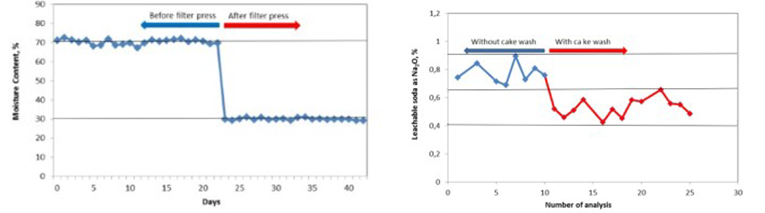

The bauxite residue storages that have been implemented in alumina refineries are summarized in this article, which also provides an overview of key factors for the success of dry stacking storage over other technologies and the role of filter press in the development of this type of disposal.

The article Bauxite Residue Management published by the bauxite.world-aluminium.org and many other papers named in the hereto articles provide a short overview of the different types of residue storage.

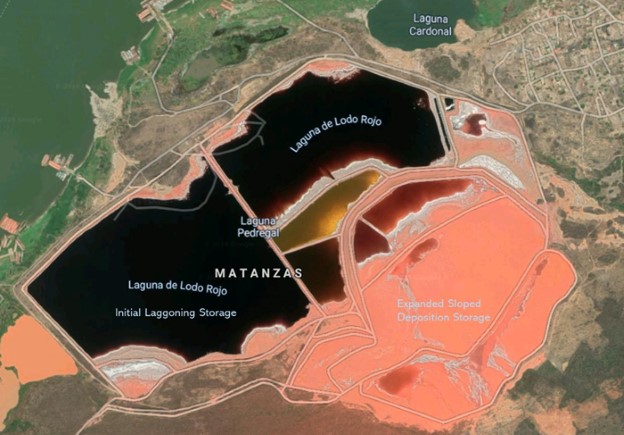

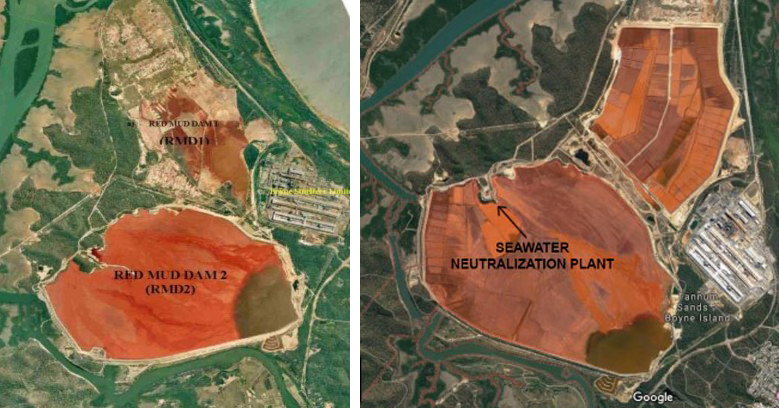

Wet disposal: residue slurry containing high content of liquid (Cooling, D. J., 2007) is disposed in lagooning ponds, barriered by dam walls. The consolidation of solids is very slow. The water management is very complex due to the enormous surface, and the collection of rainfall run-off and water return to be processed back in the refinery is negligible (Davies, 2011). This method was implemented in all alumina plants until 1975 (Suchita Rai, 2012), and after that, few new alumina refineries adopted other technologies.