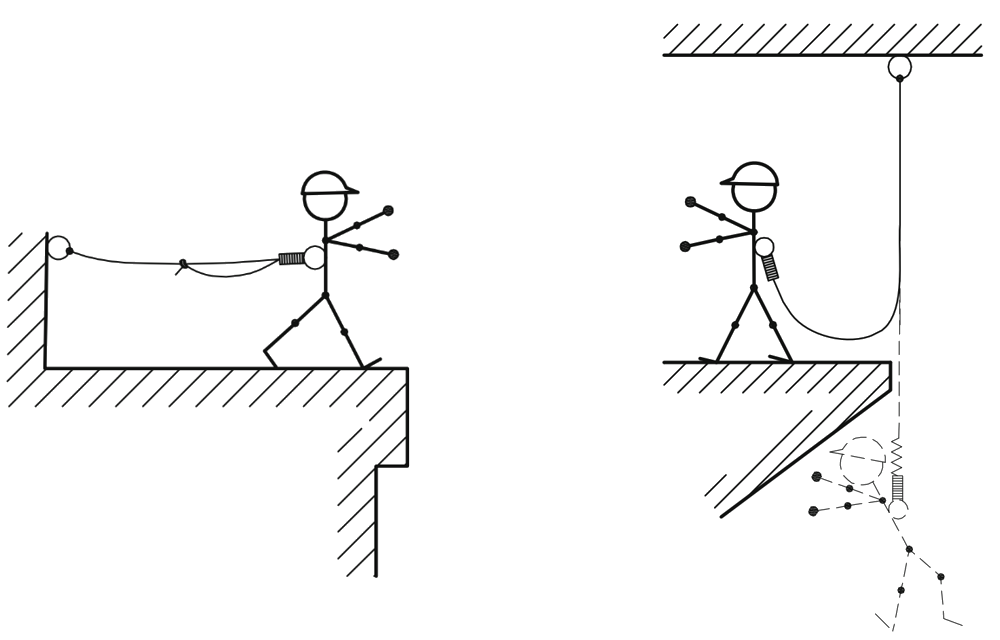

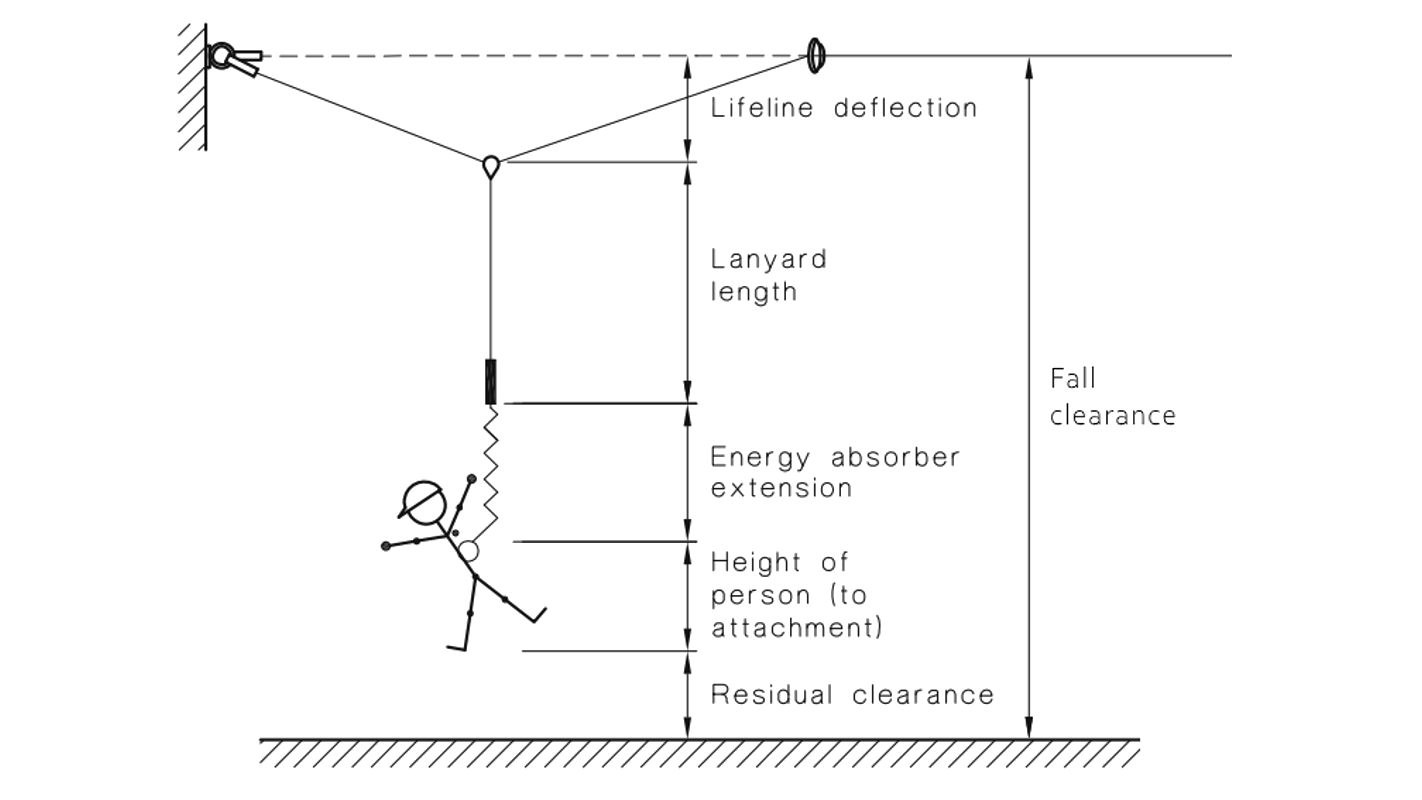

Even when using an impractically short lanyard, a best-case fall clearance height of 2.1m (AS 1891.4) or 2.8m (ISO 16024) below the main beam is required. This already eliminates most relining applications and certainly does not offer any protection for falls within the trunnion area. It gets even worse if a more standard 2m lanyard is used – then the best-case fall clearance height becomes more than 4m which makes the system completely inappropriate for all relining applications

Even if a novel system could be designed to circumvent this fundamental safety issue, there are still many other general difficulties in implementing and operating fall arrest systems. These systems require regular and often expensive maintenance, specialised storage, comprehensive training, harness wearing, hand tool tethering and exclusion zones around fall risk areas.

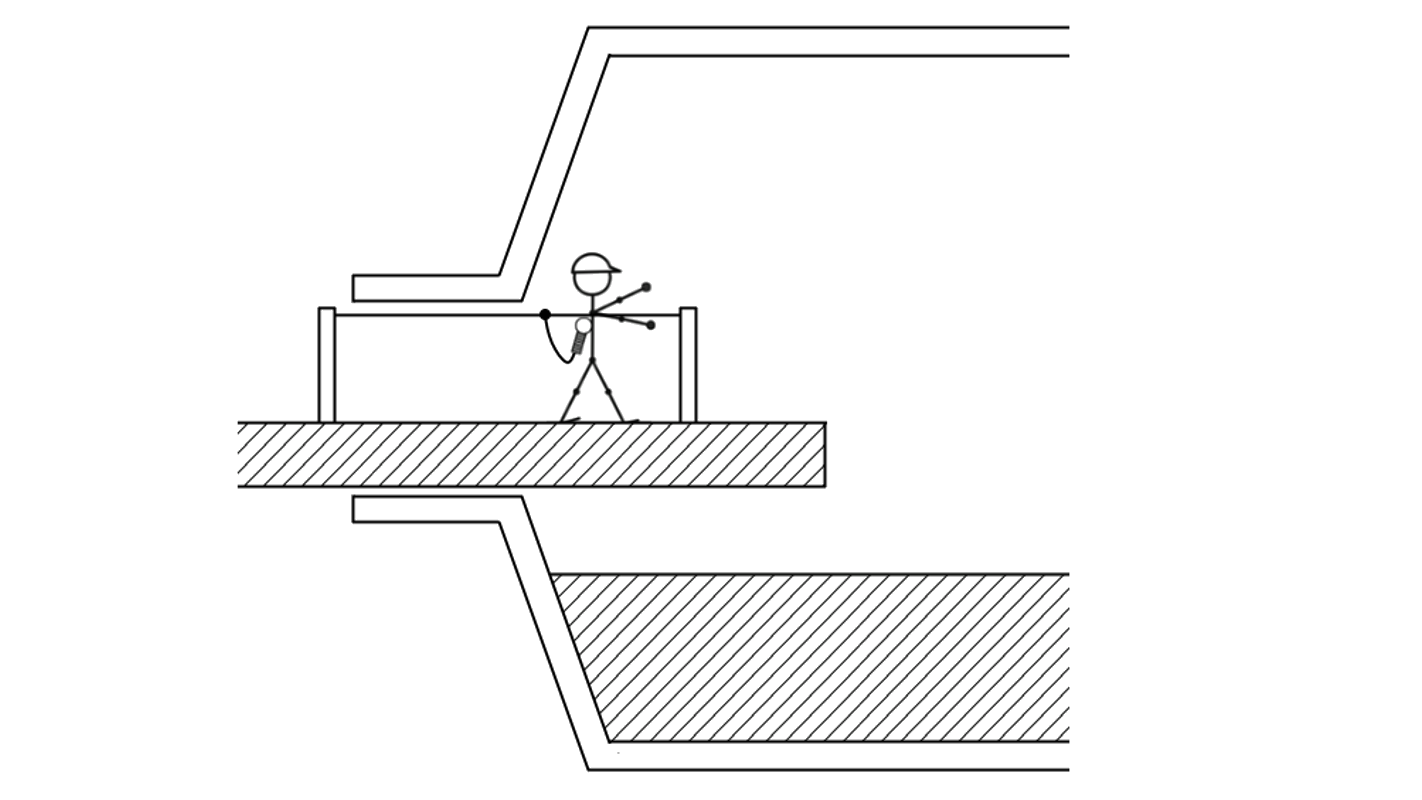

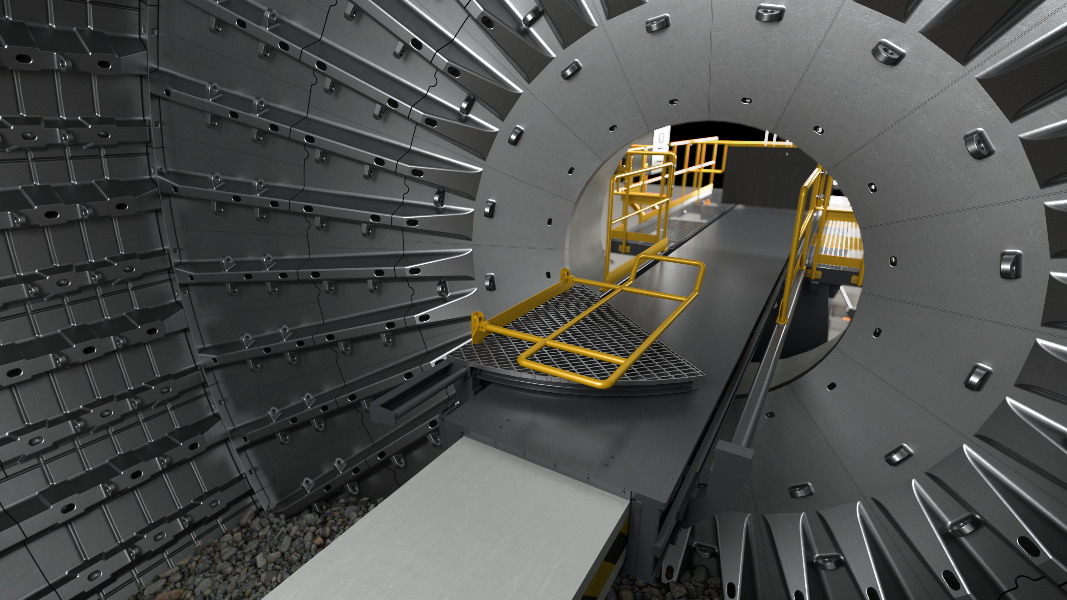

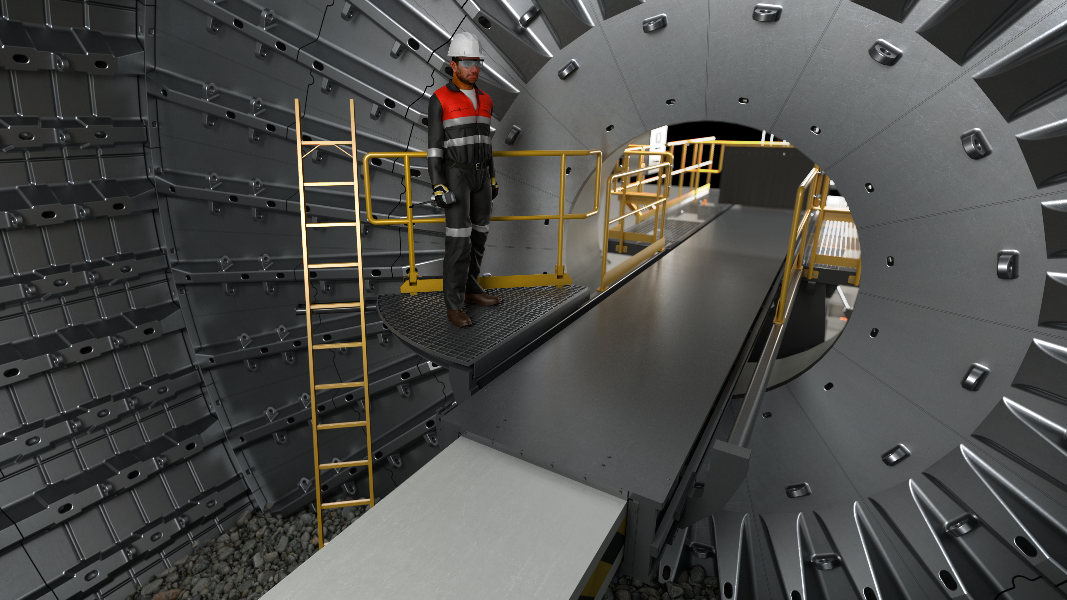

Access platform systems

Access platforms avoid the issues associated with fall arrest systems by providing a safe means of access without requiring supplementary equipment. However, there are three main design issues for this application that must be considered:

-

The system must fit through the mill opening

-

The system must comply with platform design standards

-

Erecting the system must not endanger personnel

The first issue forces the platform design to be collapsible or assembled from multiple parts. Fixed access platforms are only suitable for the very largest mill openings which makes them unsuitable for the vast majority of applications.

The second issue is perhaps the most critical – the platform design must meet relevant design standards. An access platform that does not meet design standards is more dangerous than having no platform at all. It provides a false sense of security and exposes personnel to even greater risks. The access platform must perform exactly as someone using the platform would expect. If it looks like a guardrail, it must function as a guardrail as per required specifications. This means no wire or chain barriers (expressly forbidden in ISO 11660-1) and any steelwork must fully comply with the structural, deflection and erection requirements set forth.