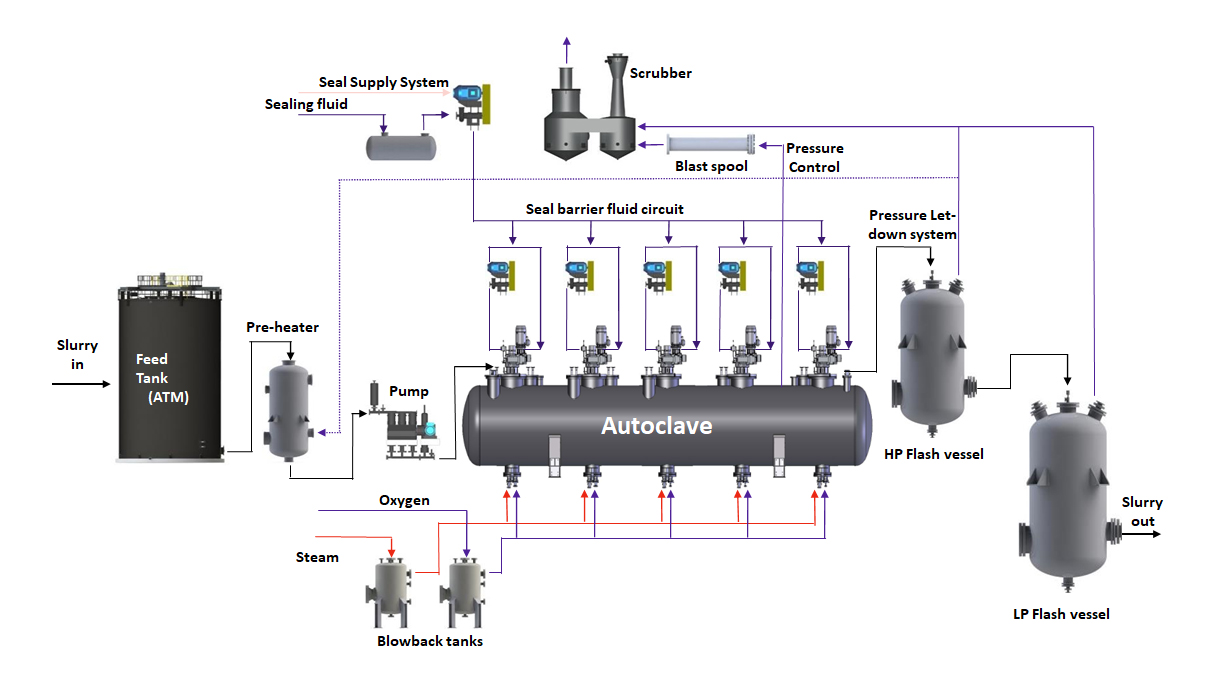

The primary equipment in the process is the autoclave, but the pressure circuit includes many other supporting pieces of equipment. Two of the biggest challenges for the equipment during pressure processes are corrosion and erosion. The slurry that travels through the equipment is typically acidic, meaning it causes wear over time.

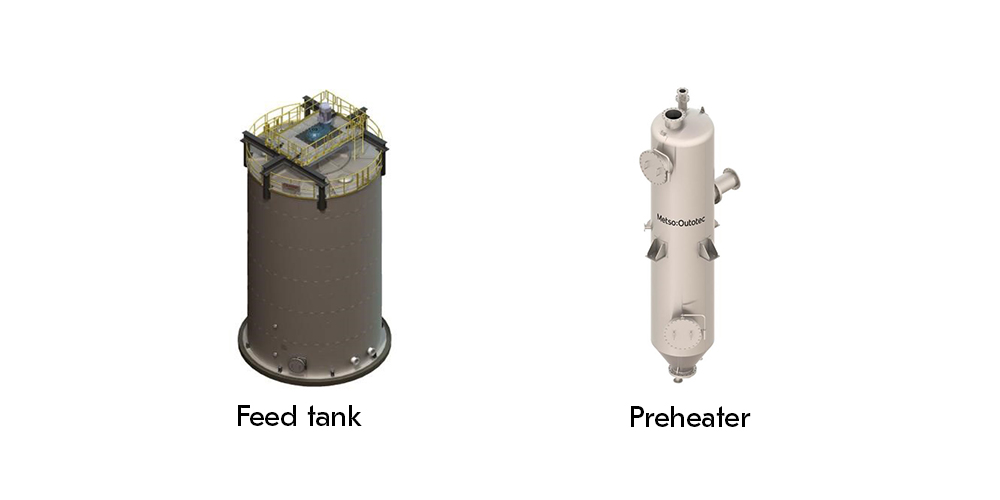

The process starts with mining the ore, which is then crushed to a fine material so that it can be mixed with water. The next step is to pump the slurry, consisting of water and fine solids, into the autoclave. The temperature and pressure in the autoclave are much higher than in atmospheric conditions. Exothermic processes create heat and typically require cooling in the form of, for example, a quench water feed or internal cooling coils. Endothermic processes on the other hand require external heating. Preheaters that use ventilation steam from flash vessels can be used to raise the temperature of the slurry feed prior to the autoclave. If needed, heating during operation is usually done with a steam feed.

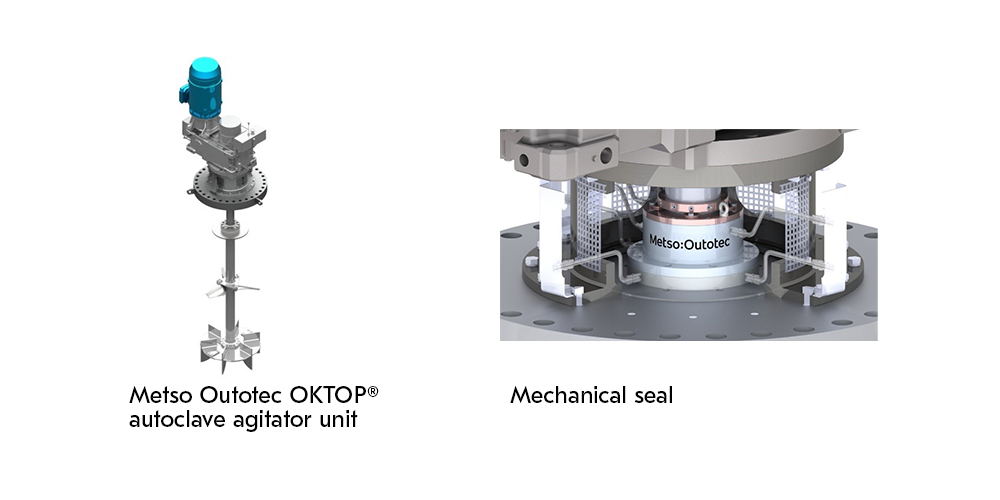

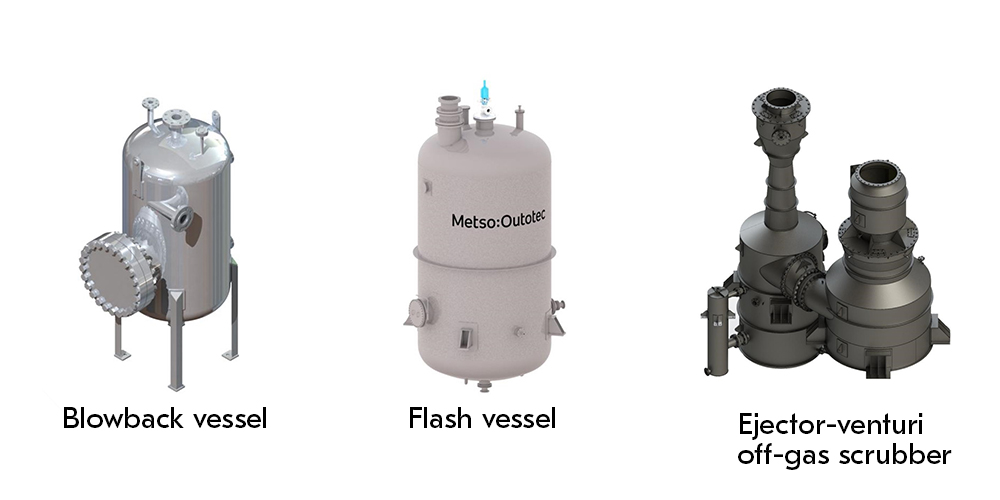

Inside the autoclave, utility gases and steam are fed through the blowback vessels. The slurry flows through the autoclave and is mixed by the agitator units throughout the process. At the end of the autoclave is the slurry discharge outlet. After the autoclave, the slurry is brought back to atmospheric conditions via one or several flash vessels. When the slurry exits the last flash vessel, the product of the autoclave process can be used for further refining. A generic autoclave process, including the different equipment and how it is connected, is illustrated in figure 2 below.