Fulfilling climate targets requires actions from the steel industry

We can see the adverse effects of the climate change in the everyday life of people around the world for instance as extreme weather conditions. To combat the negative impacts, we need actions especially in energy production and transportation, but also in other sectors, including the steel industry, which generates around 8% of the global CO2 emissions. Consequently, decarbonizing actions within the industry play an important role in achieving the targets. Radical cutting of emissions will require a technological step-change and creation of industrial ecosystems that enable zero-emission or low-emission production of energy and steel and the best possible utilization of side products.

New technology with potential for significant emissions cuts

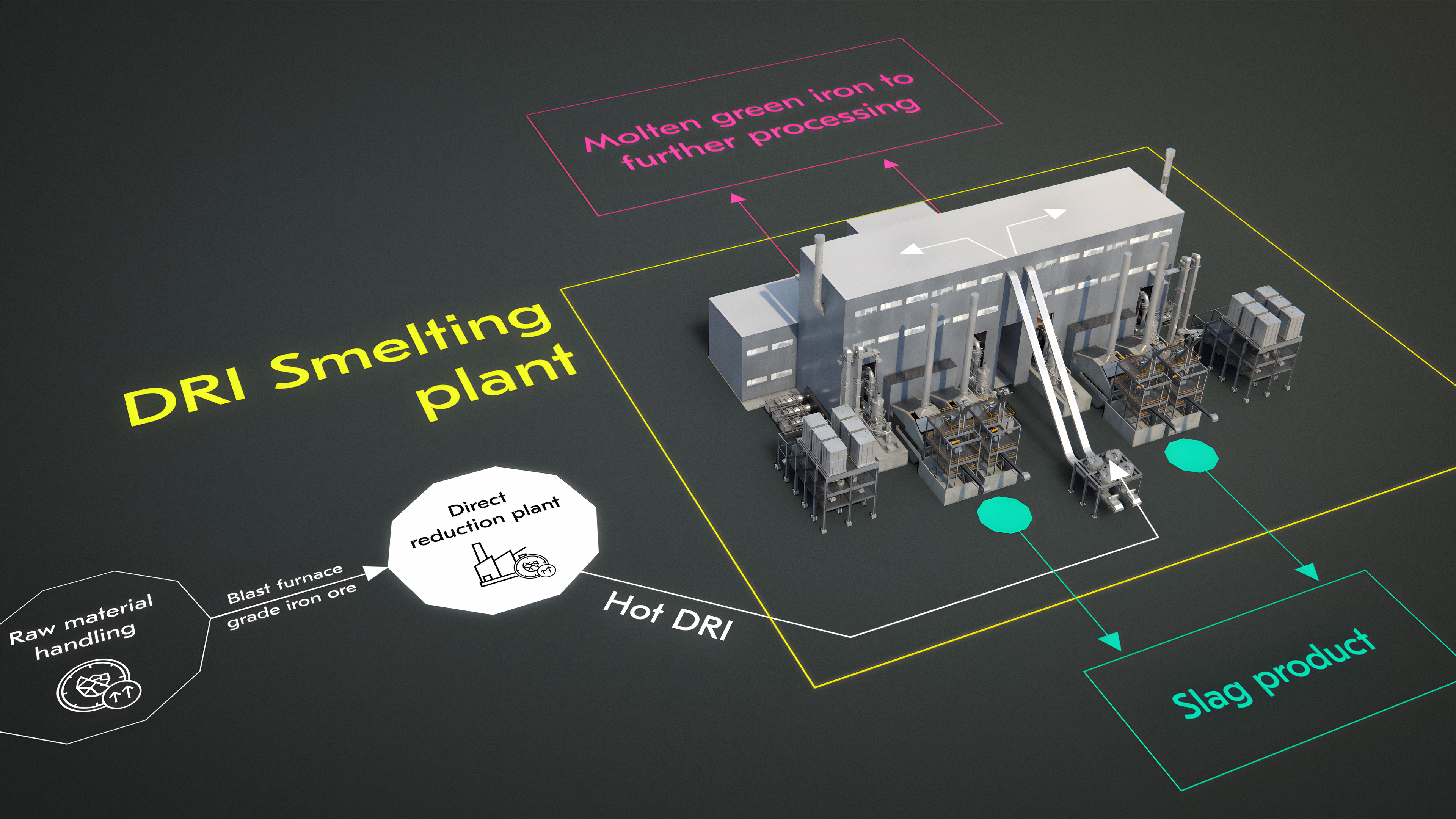

The conventional steel production where oxidic iron ore or concentrate is reduced and melted to metallic iron with fossil carbon accounts for about 1.9 tCO2/t of produced steel. When this blast furnace process is replaced with Metso’s solution for direct reduction of iron concentrate and electric melting, the CO2 emissions can be as low as 0.2-0.9 tCO2/t per produced ton of steel. Iron is reduced in solid state by using ammonia, coal, hydrogen or natural gas, and the resulting direct reduced iron (DRI) is melted in an electric furnace preferably with renewable electricity. The electric furnace can be a conventional arc furnace for scrap melting (EAF) or Metso’s novel Outotec® DRI Smelting Furnace (ESF) that is based on submerged arc furnace technology utilizing partially open slag bath operation conditions.

The most important benefit of Metso’s Outotec® DRI Smelting Furnace is its ability to handle large amounts of slag. This is essential as it enables the usage of the current blast furnace grade iron concentrate. Otherwise, the producers should shift to cleaner and more expensive feed material that is not available in required quantities. Currently, blast furnace grade iron concentrate accounts for 90% of all iron concentrates produced. Offering decarbonization possibilities for the conventional processes generates real impact and is necessary for the decarbonization of the steel industry.

The DRI smelting furnace is also flexible regarding the feed material properties: it can be hot or cold DRI, reduced with carbon or natural gas that are currently available, or reduced with hydrogen when that type of feed material is available in sufficient quantities. The properties of the produced hot metal allow retaining the further processing and refining steps as they are – a huge benefit for the producers.