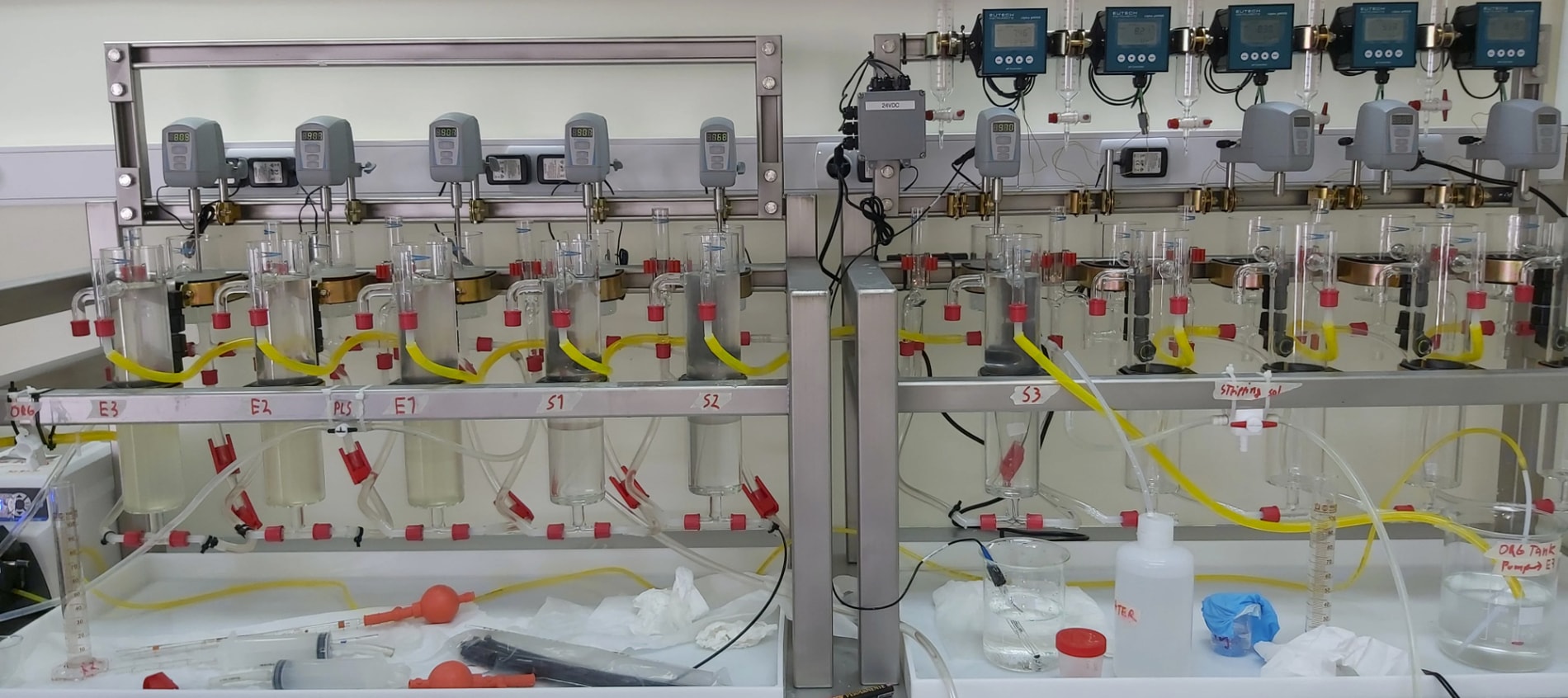

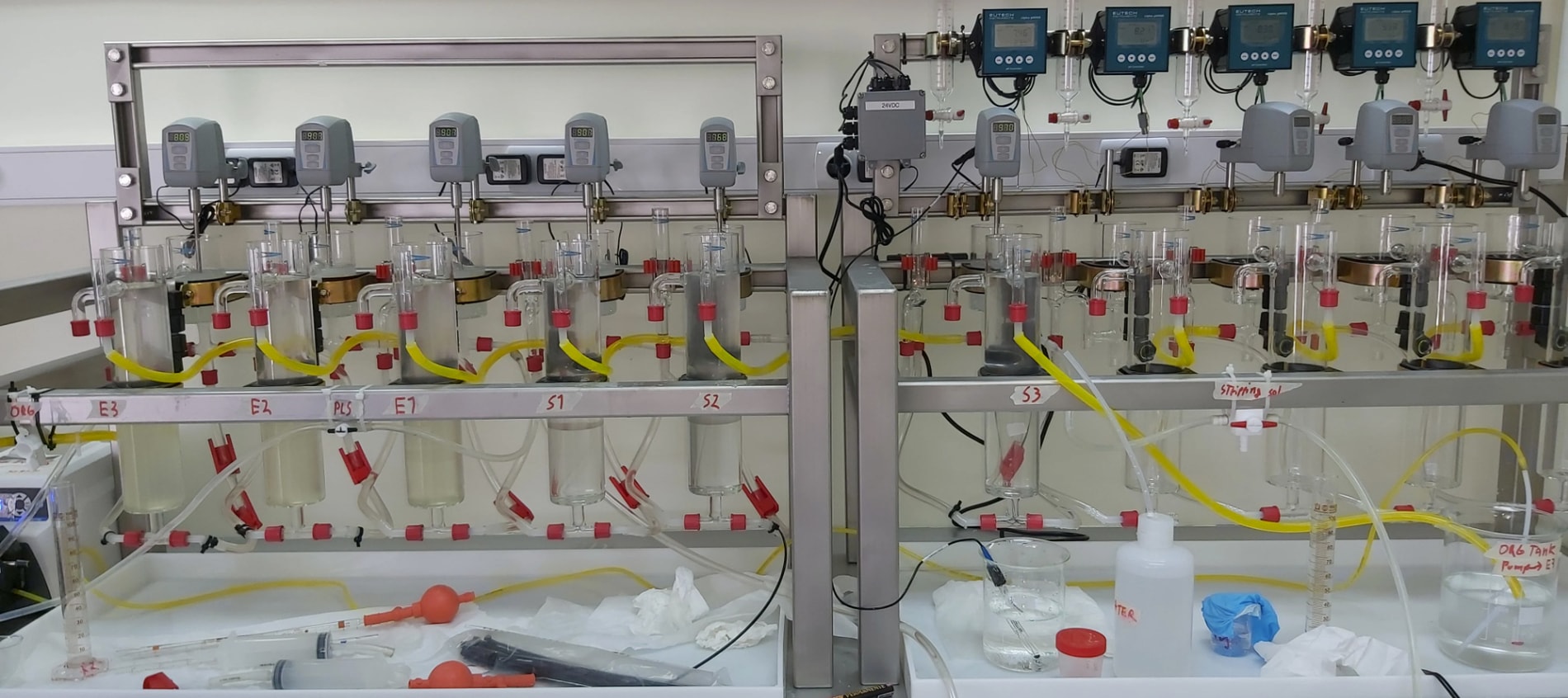

Outotec has implemented the equipment needed to perform continuous piloting test work using local brine, simulating different impurity removal steps and lithium carbonate precipitation.

Continuous development and improvement mindset – lithium brines processes

1. Impurity removal by precipitation

The first process tested for the brine purification consisted of two steps with solid-liquid separation in between.

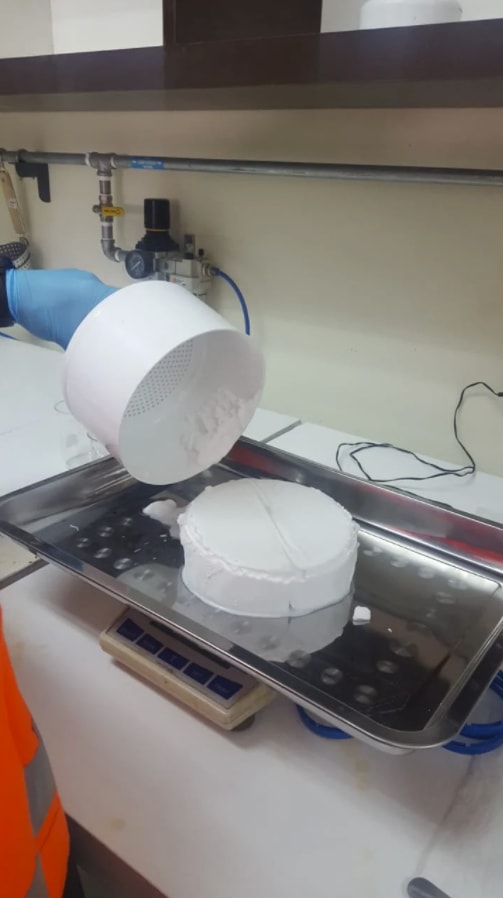

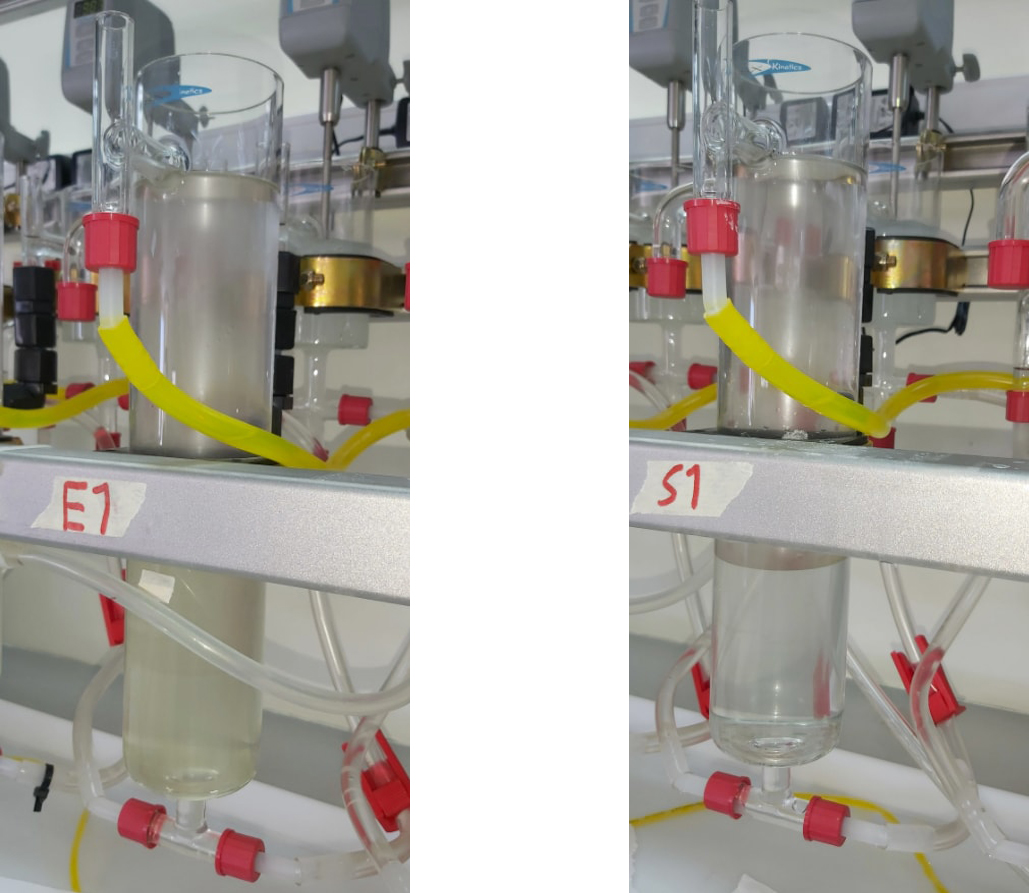

In the first step, magnesium and part of the sulfates are precipitated in two continuous agitated Outotec OKTOP® reactors with a heating control system and Outotec OKTOP® impellers to ensure proper homogenization and precipitated particle growth. This is in order to achieve optimal dewatering conditions. The reaction took place at approximately 65oC, reaching excellent magnesium removal levels and close to the gypsum saturation level for the sulfate concentration. The precipitate is filtrated with pressure filters to recover most of the pre-purified brine.

In the second step, the remaining sulfate and the calcium are precipitated using a similar configuration to the first step, using two Outotec OKTOP® reactors in series with a heating control system and Outotec OKTOP® impellers. The precipitation took place at approximately 65oC, generating a properly purified brine for the next process step.

2. Lithium carbonate precipitation

After purification the brine lithium carbonate precipitation process step where reaction takes place at 85oC in Outotec OKTOP® reactors and impellers. Proper agitation, the correct temperature, and control over reagent addition enables production of technical and battery-grade lithium carbonate. Once precipitated, the slurry is fed to a pressure filter where the cake is dewatered and efficiently washed to achieve excellent impurity and moisture levels.

3. Boron solvent extraction

Outotec has also implemented a continuous solvent extraction capability, which has been tested with local lithium brine. The equipment makes it possible to fine-tune the extraction and stripping stages to develop the best process solution for the application in question. This is extremely valuable due to the huge variation in brine composition in the area.

The personnel responsible for the laboratory and equipment in Chile have reported that this setup allows us to provide customers with quick responses and the highest-quality technical support.