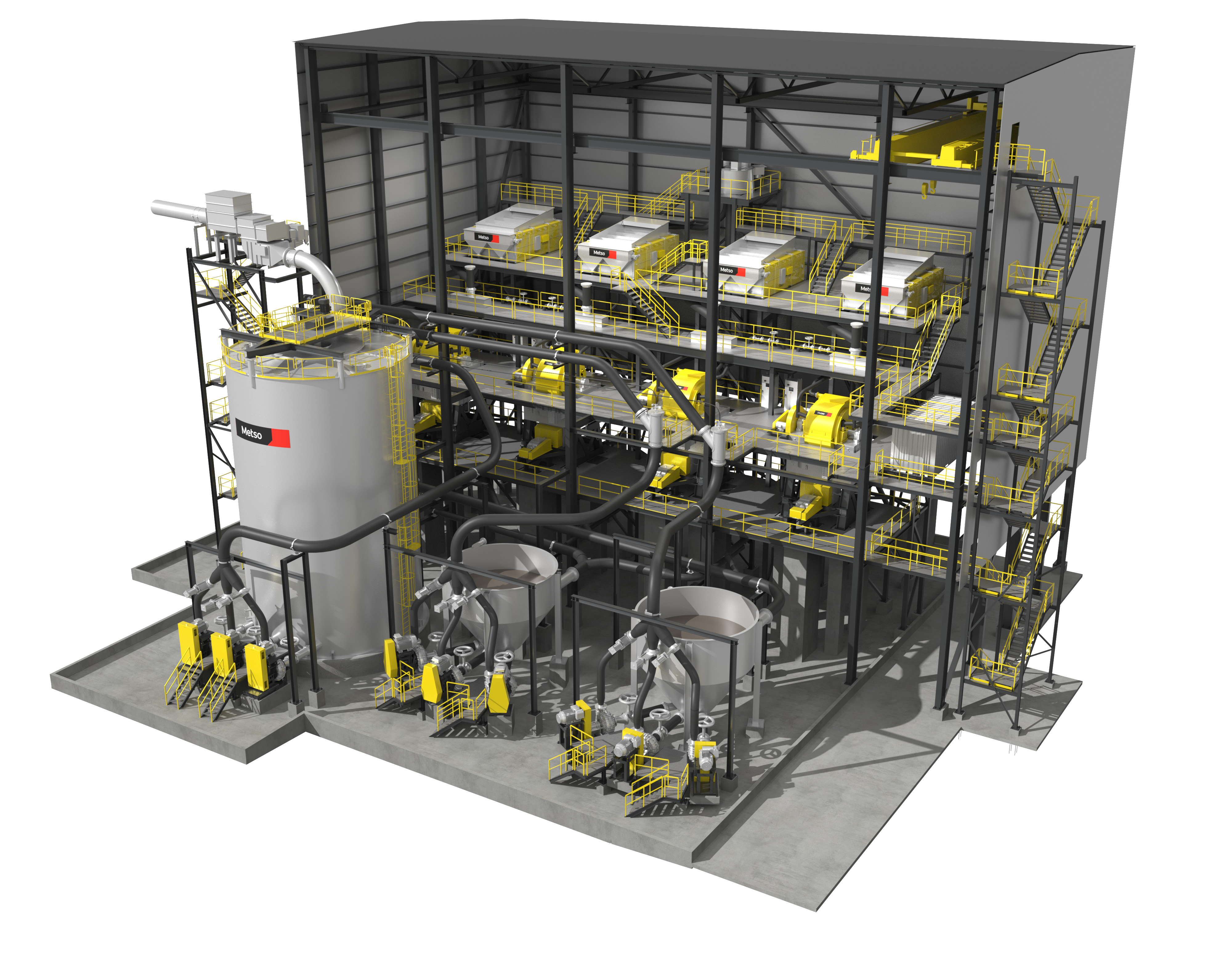

Ensuring minerals and metals processing plants’ maximum performance and competitive advantage starts already in the early phases of a project. The design of the most optimal flowsheets usually requires expert support, for example, with testing, simulations, studies and pilot campaigns. Metso’s unique metallurgical competences, supported by its extensive testing and piloting facilities, can offer these services as well as basic engineering with equipment selection for complete concentrator plants, tailings processing or single plant units.

How can Metso support its customers with flowsheet design and equipment selection?

Metso’s capability with its process flowsheet development competences and expertise is unique on the markets. Our focus is providing the best solutions to our customers for more added value.

To create the most value for our customers, early involvement in projects is essential. In practice, this means developing and selecting optimal process flowsheets with laboratory and pilot test work, simulations and various levels of studies already during the project development phase.

By doing this, we can support in Planet Positive process flowsheet design and equipment selection for maximized process efficiency and throughput. Automation, pumps, hydrocyclones and valves can also be included in the design and provided by Metso, in addition to the main processing equipment.

Naturally, Metso can also join the project in the later stages, when the customer wants to ensure the basic engineering for metallurgical process guarantees.