Oxygen Enrichment

A number of TSL copper and nickel smelters have enriched the lance air to 70–80 vol.% oxygen, resulting in reduced fuel consumption and process off-gas volume. Increased oxygen usage in these applications has the potential to decrease CO2 emissions by more than 40%, with just a 2% increase in total oxygen consumption.

In reducing process applications such as zinc residue smelting and slag reduction, fossil fuel introduction is required both to provide energy and to reduce oxide species in the feed. In these processes, lance air oxygen enrichment is limited to around 45 vol.%, as higher enrichment can lead to more rapid wear of the lance tip. To overcome these limitations, Outotec has developed and commercially implemented a fluid-cooled lance capable of operating with >90 vol.% oxygen. This lance design not only reduces CO2 emissions by 20% compared to an air-cooled lance, but also provides a significant improvement in lance lifetime to more than 30 days.

Low-Carbon Fuels

The inherent flexibility of the Ausmelt process to utilize solid, liquid, or gaseous fuels allows for the lowest-cost fuel available to be selected, but also offers opportunities to reduce CO2 emissions by using low-carbon fuels such as natural gas. So called ‘advanced fuels’ (i.e. those not derived from fossil fuels) including electronic waste (e-waste) and automotive shredder residues (ASR) have also been processed at plants in China, Japan and Korea. Outotec has conducted pilot tests investigating the use of other waste streams such as shredded automotive tyres and sewage sludge, which highlighted the significant potential offered by these materials to offset fuel and reductant consumption in both oxidizing and reducing processes.

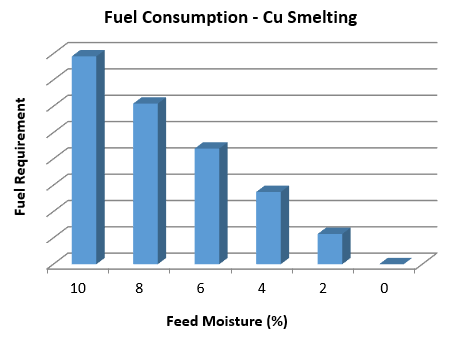

Dry Feed Injection

Feed drying using WHB steam and the subsequent processing of low-moisture copper and nickel concentrate feeds is a cornerstone of the Outotec Flash Smelting process and can reduce CO2 emissions by as much as 60% compared with the treatment of undried concentrates. Dry feed injection via the Ausmelt Lance has the potential to provide a step-change in energy efficiency for process applications such as zinc residue smelting, for which feed moisture levels are typically 30–40 wt.%. Lance injection of granulated Ni-PGM matte at more than 40 t/h is used by Anglo American Platinum at their plant in Rustenburg, South Africa. Injection of WHB dust via an Ausmelt Lance at the Kalgoorlie Nickel Smelter in Western Australia was also carried out for a number of years to maximize concentrate throughput.