According to the International Energy Association (IEA) forecasts,the demand of copper can reach even 30 Mtpa in 2030, which translates to a +25% increase to today’s level. This is a tall order since the existing operations can only produce so much and developing new supply capacity takes time. As a result, we can expect copper price to increase, and this will drive new investments respectively.

At the same time as we need to increase the production of copper to support the boom in electrification, we need to put continuous effort into reducing the emissions that processing of copper and other necessary minerals and metals produce. In general, copper is not the most energy intensive metal to produce, but as new deposits are becoming much harder to mine and typically contain less copper in ton of ore than some 20 years ago, more processing is needed. Also, higher amounts of impurities, such as arsenic, are becoming the rule, not an exception.

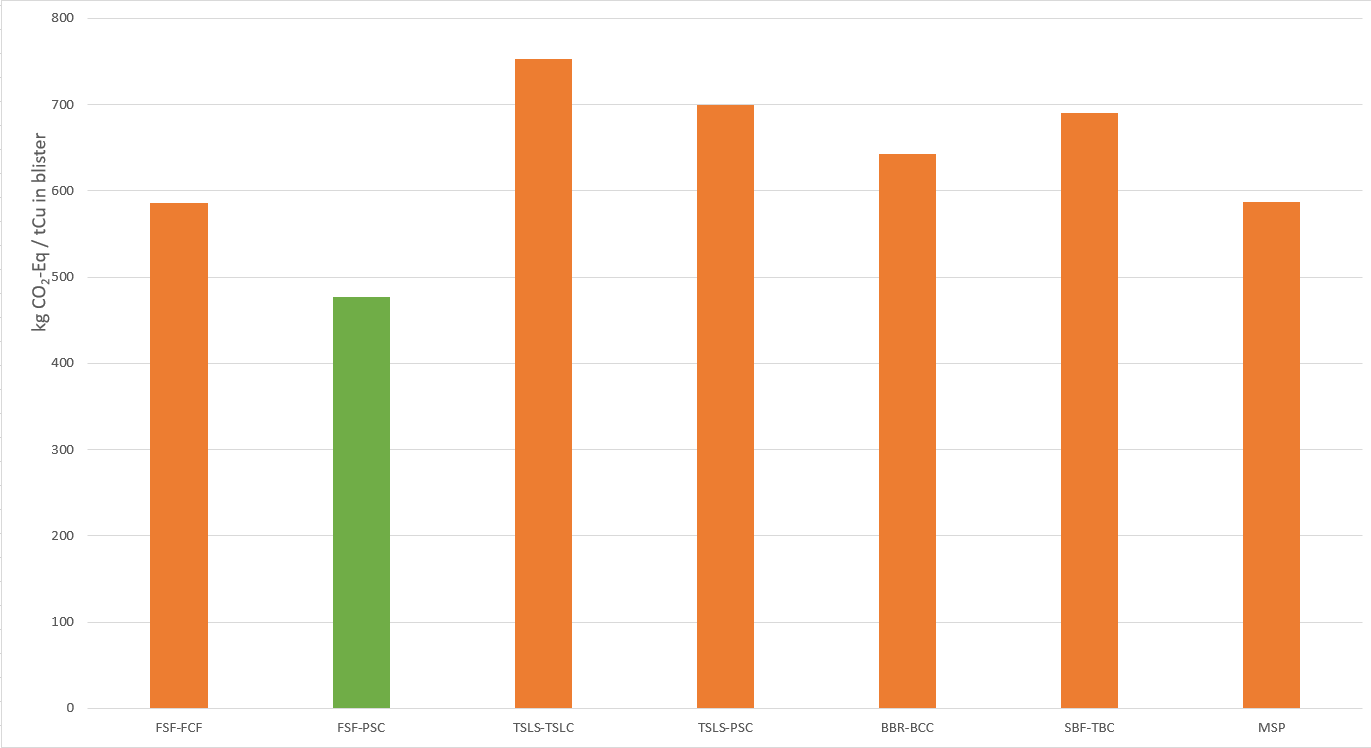

Until now, there hasn't been reliable comparison of emissions produced with different copper smelting technologies. Our experts Christina Alexander, Hannu Johto, Mari Lindgren, Lauri Pesonen, and Antti Roine took the challenge and developed a systematic method for this, continuing the LCA pioneer work of Professor Reuter in 2015.

The findings of the team were recently published at ScienceDirect, the world's leading source for scientific, technical, and medical research.