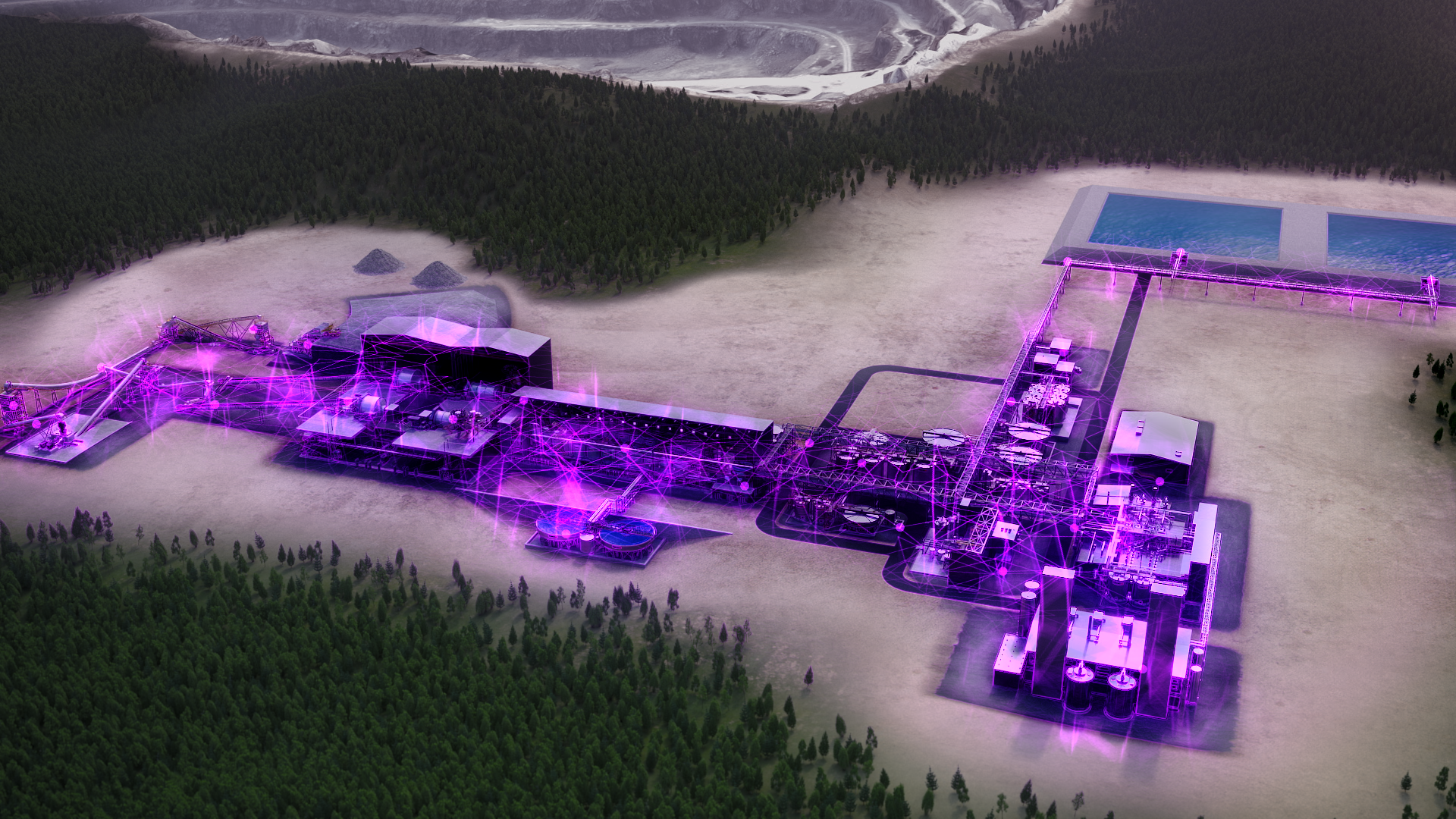

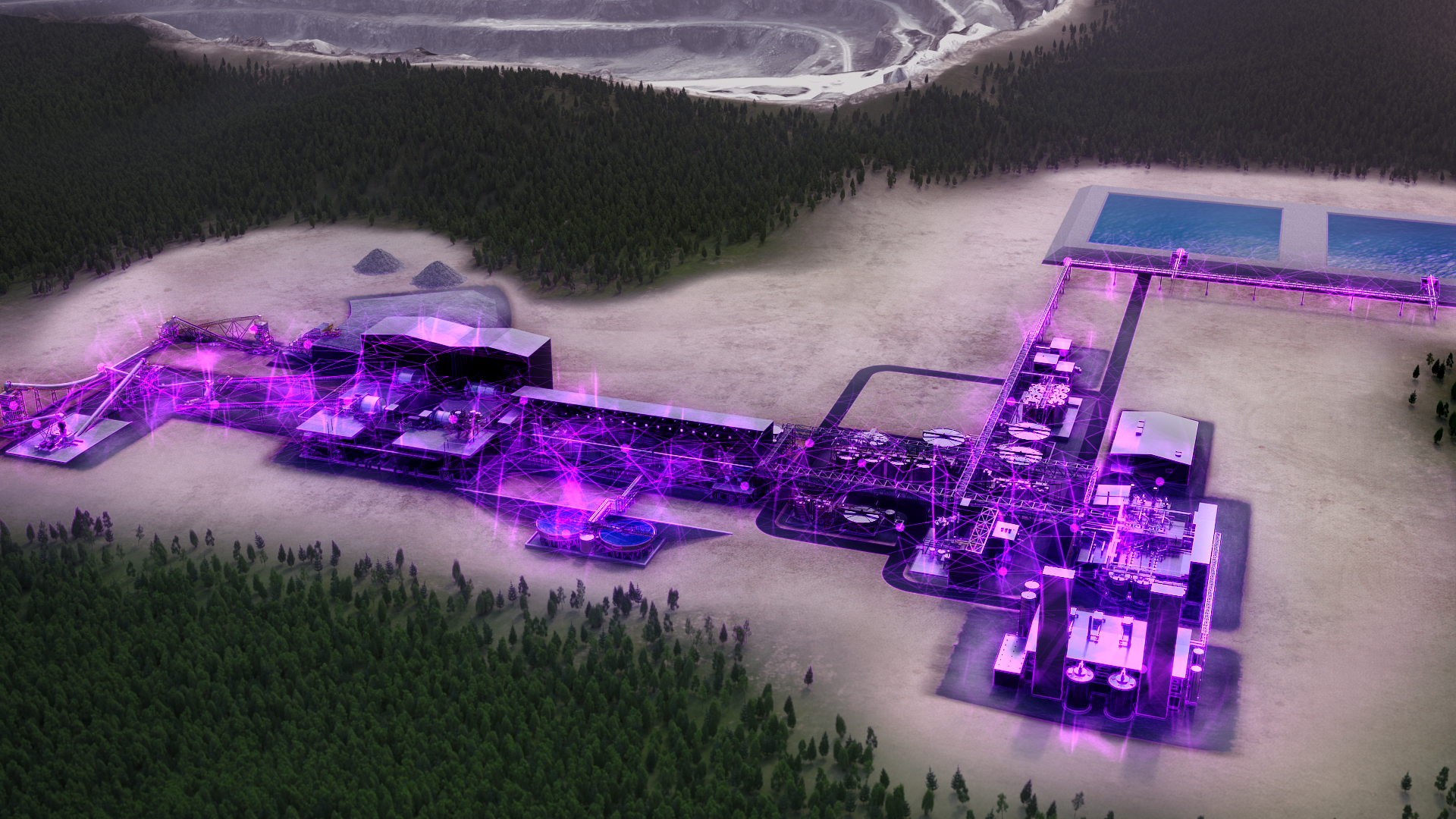

The mining industry is facing various challenges, such as reducing carbon emissions, coping with changing ore grades, conserving energy and water, and attracting digital-savvy talent – all whilst trying to optimize equipment, process and operations performance. To tackle these hurdles and usher in a new era of efficiency, the industry is turning to digitalization. This transformative solution provides data transparency, enables timely actions, and allows for a more sustainable, safe, and efficient production.

“Our customers are aiming for drastic savings on energy and water consumption, and are also facing the challenge to attract the young digital-savvy generation,” says Rashmi Kasat, VP, Digital Technologies. “What they need now in this situation is a step change, and the answer is digitalization.”

With the rising demand for environmental responsibility, reducing carbon footprints has become a key priority. Digital solutions play a pivotal role in streamlining operations. This makes processes more sustainable, thus enabling mining companies to achieve their zero harm objectives.

Tuomas Martinkallio, VP, Digital Services, highlights the criticality of digital tools as they provide data transparency. This allows operations increased availability and reduced plant downtime. Through digitalization, sites can access valuable insights and make informed decisions. By harnessing the power of digital technologies, they can extract, analyze, and leverage data to drive operational efficiency, identify areas for improvement, and streamline processes.

“The global events we have all experienced recently have only made digitalization more relevant than ever,” says Tuomas. “On the operative side, we are augmenting the expertise with digital tools. On the maintenance side, it’s having the right parts available and making shutdowns shorter and more controlled. We are now combining the physical and digital world, and this link is here to stay.”