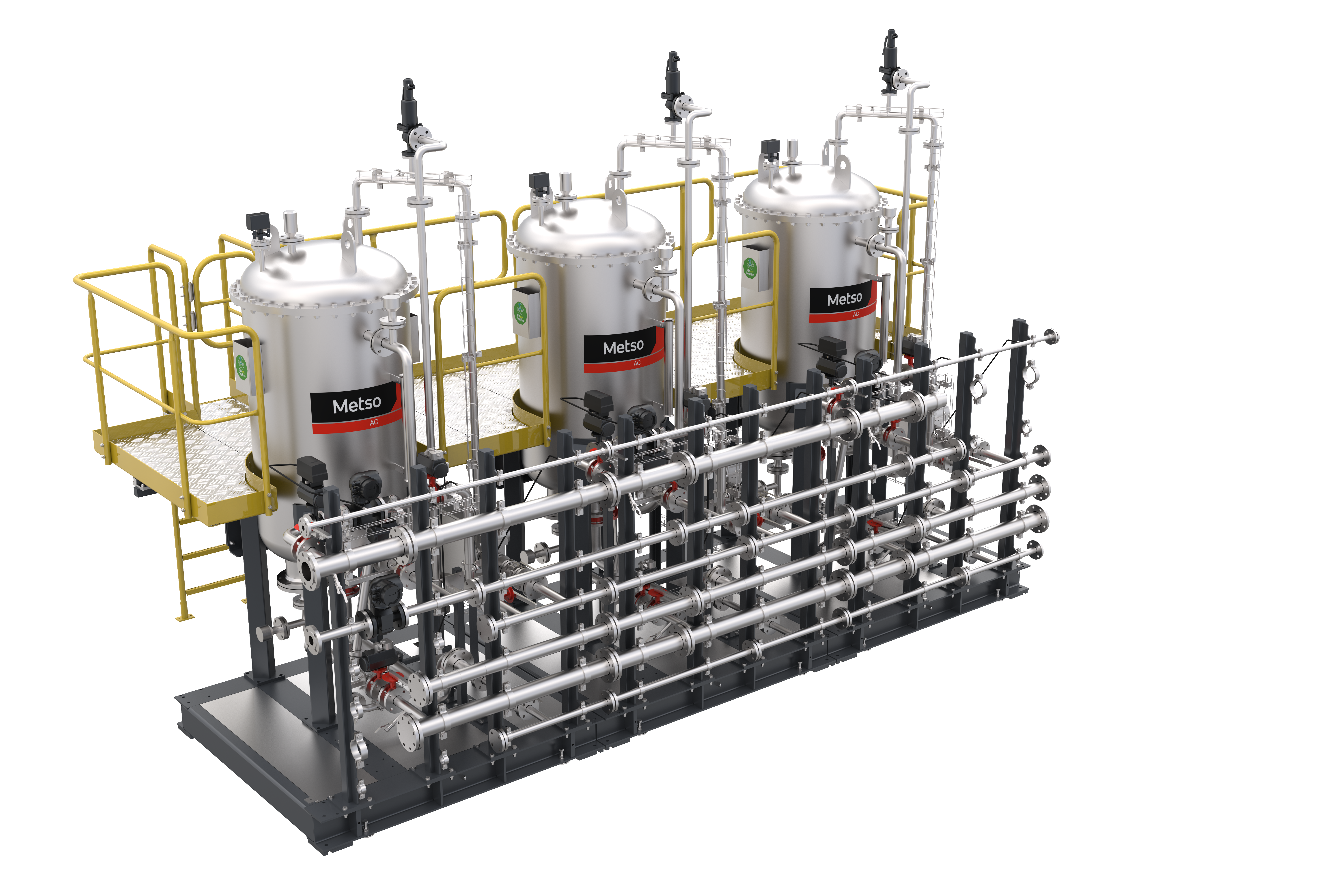

Activated Carbon filter

Launched in 2022, the AC filter emerged as a response to an emerging demand. Fueled by customer inquiries and the insights of Metso's hydrometallurgical department, the AC filter bridged a crucial gap in filtration capabilities. Its conception was propelled by the necessity for a specialized filter that excelled at eliminating dissolved organics, a challenge that conventional filters struggled to address.

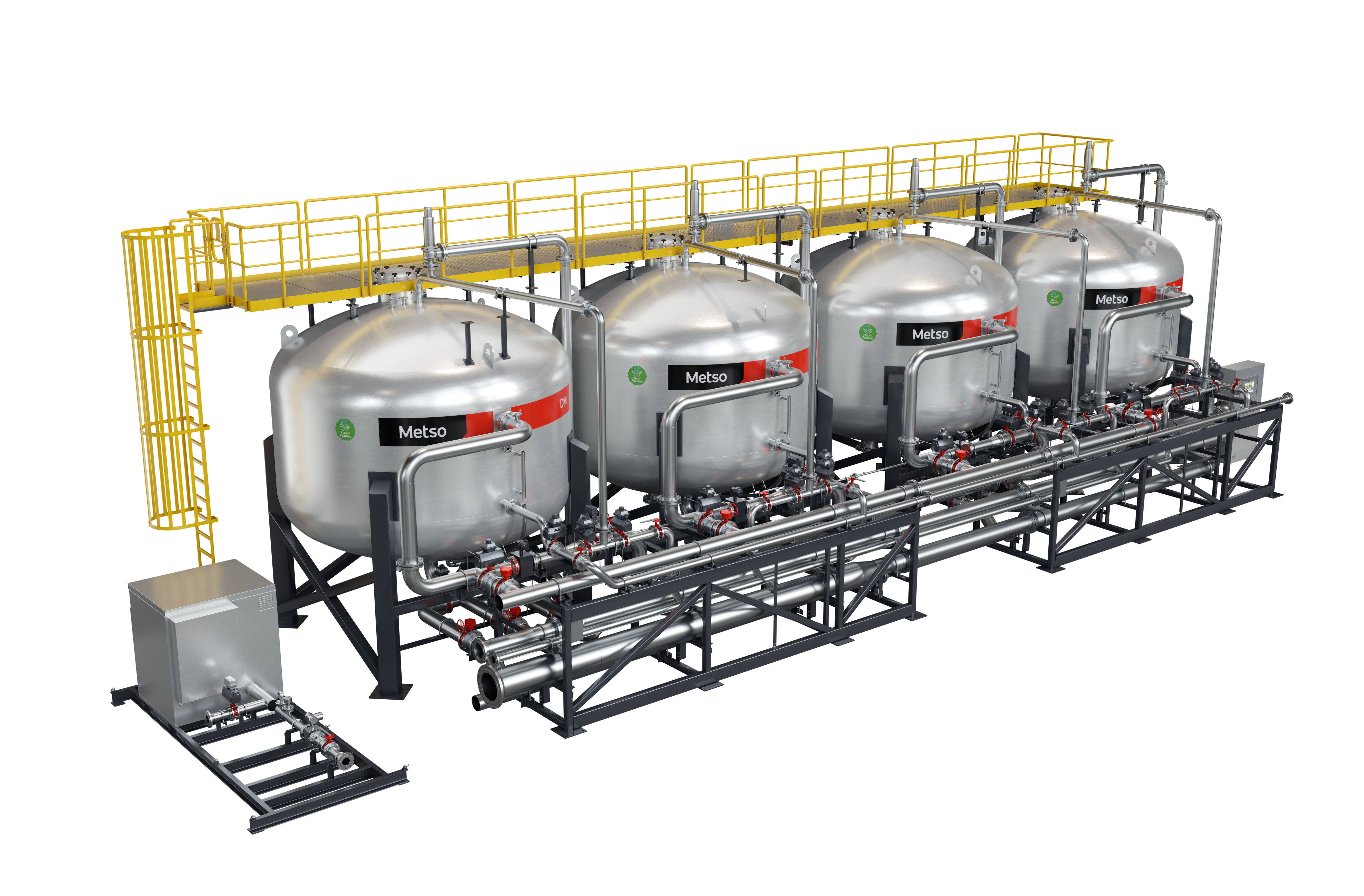

Mechanically, the AC filter is very similar to the DM filter, but in this case, there is only one filter media inside the filter - and that is activated carbon. Following a top-to-bottom feeding process, the filter goes through the activated carbon media and the activated carbon removes organic compounds from the process stream. This process is more efficient for dissolved organics, since they can be adsorped into the activated carbon, thus yielding purer liquor.

The AC filter is based on nearly a century of experience and strengthens the Metso filtration portfolio even further with its cost effective and modular design, increasing recovery and recycling of valuable process chemicals. This filter also optimizes backwashing using filtered process liquid. This minimizes water usage while simultaneously reducing energy consumption due to its low pumping pressure, adding a layer of sustainability to its efficiency.

The AC filter becomes an ideal choice when the solution is already free from suspended solids and when a very clean solution filtrate is needed. It is also used for raffinates, when a very clean solution is needed to follow SX steps to ensure that the remaining solvents and reagents from previous extraction step do not pass to the following step.

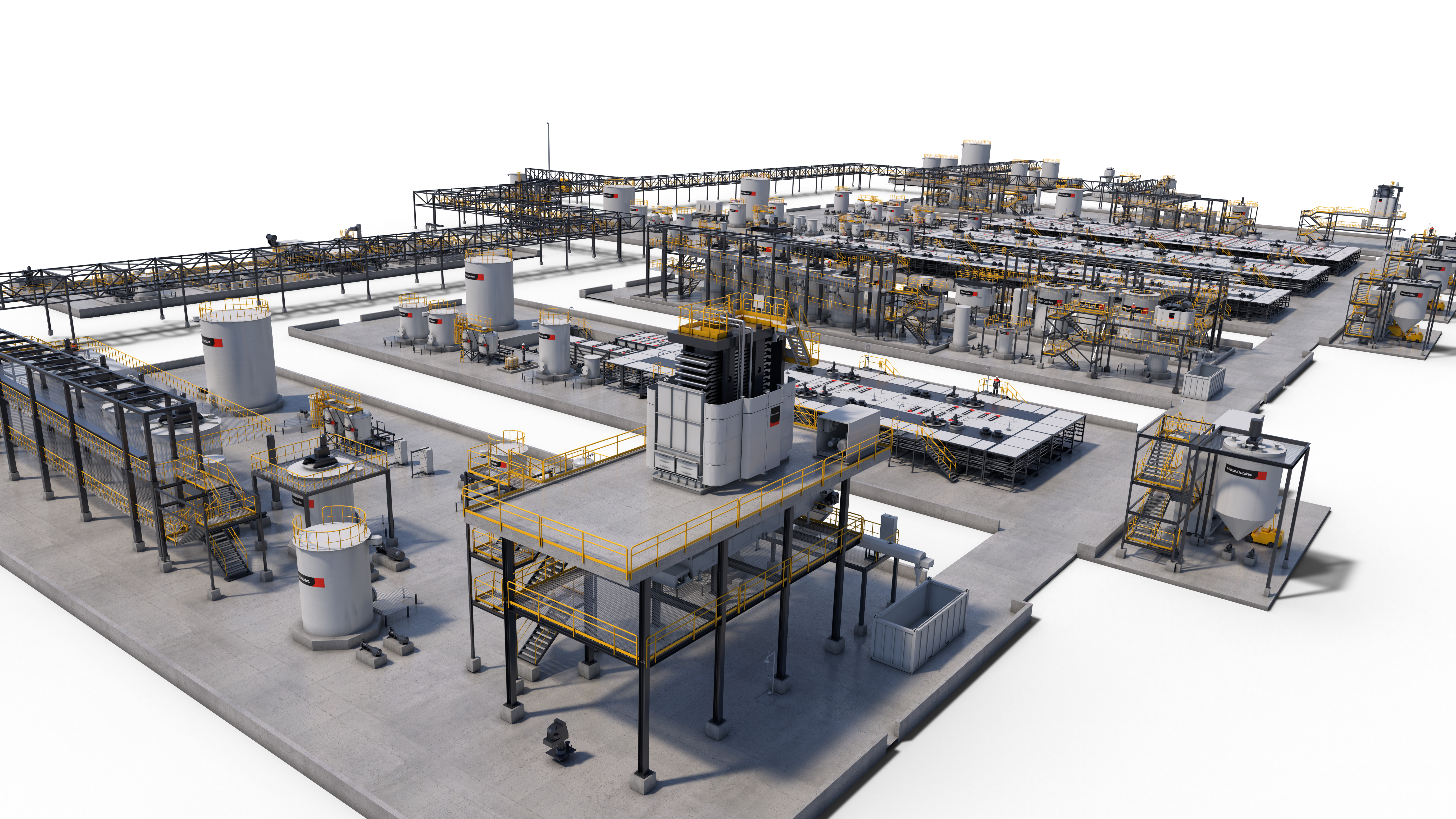

Driving the sustainable energy transition

Metso supports circular economy and responds to the growing battery minerals demand by supplying sustainable solutions for filtration in battery minerals.

Evidently, both the DM filter and AC filter embody Metso's dedication to minimizing environmental impact. Their low operating pressure translates to reduced energy consumption and lower operational costs, fostering a greener approach to filtration. These filters have also been designed to utilize filtered product. Process liquid is a filtrate, so by utilizing this as a backwash liquid, water is no longer needed for washing the filter.

“The rise of technology and the obligation to minimize our environmental footprint continue to be the catalyst for this growing demand,” says Timo. “Batteries for electrical vehicles and other types of equipment are most commonly using batteries as a source of power. This will continue.”

The efficiency of these filters can lead up to a remarkable 15% decrease in energy usage, attributed to prolonged cycle times and low operational pressure. Furthermore, they minimize water consumption by a staggering 90%, utilizing filtrate for filter backwash operations. The absence of moving parts in these filters also translates to less maintenance, as their unique media cleaning system ensures extended media lifespans.

Both filters are a part of Metso’s Planet Positive portfolio. Planet Positive is our all-encompassing approach to sustainability, which covers the environmental, social and financial aspects. Our Planet Positive offering has a central role in our sustainability agenda and 1.5 °C journey as it represents the key means of improving the resource efficiency of our customers’ operations.

Metso’s filtration offering for battery minerals optimize our commitment to sustainability, as they seamlessly integrate operational efficiency with environmentally responsible practices. As the mining industry marches towards a more responsible future, these filters stand as beacons of innovation and conscious resource management. That’s why, together, we are the partner for positive change.