Liner weight vs. wear life

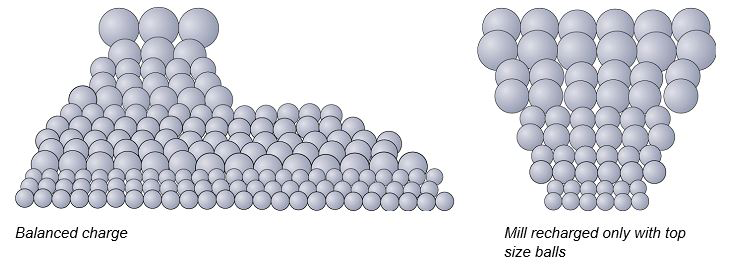

There is often a trade-off between liner weight and wear life. A lighter lining is generally thinner and, unless the design is highly optimized, it will have a shorter wear life. However, liner weight and long wear life don’t always have to be contradicting. By mixing and blending different types of liners – metallic, Poly-Met and rubber – in the same design, and by using each type where it performs best, it is possible to minimize the weight and still maintain or even increase the wear life.

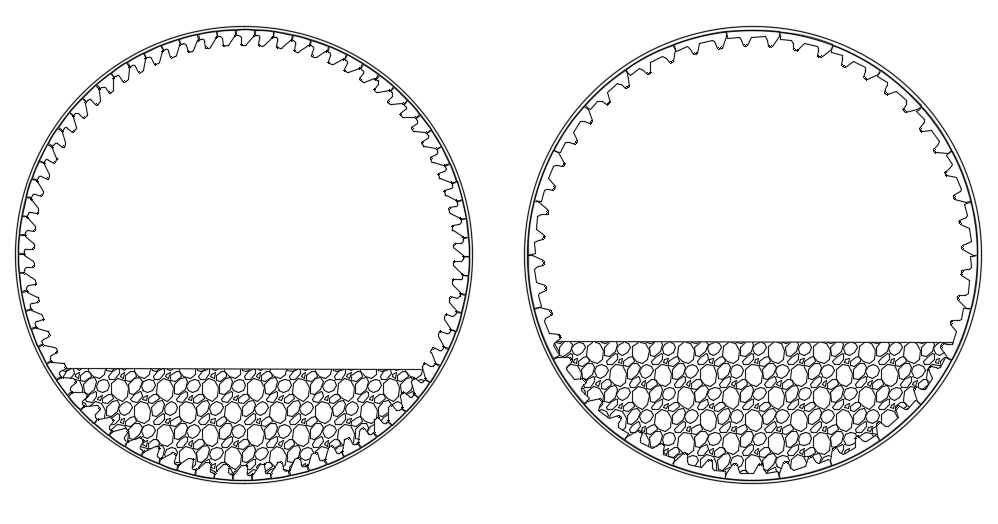

A light liner in itself does not save energy. It does somewhat reduce the load on the bearings etc., but the real benefit of a lighter lining is that the mill can carry a higher charge without exceeding the maximum weight. While it isn’t possible to add media directly equivalent to the weight saved, it is also impossible to add enough to increase the mill utilization.

There are many old mills out there that are worn and torn by operation, and it is not unusual that the mill structure and bearings cannot take the same load as they used to. By minimizing the weight, it can be possible to prolong the life of such equipment.

2. Maximizing mill liner size and minimizing mill liner parts

Back in the day, mill liners were carried and installed manually, which required a lot of man-hours – and muscles. Thus, the liners couldn’t be very heavy and there were many parts to be installed. However, downtime wasn’t much of an issue, because there were many small mills on site.

Nowadays, things are different. The fact that mills are much larger has changed the game completely. Higher production means a much higher wear rate as well. Considering the high throughput of big mills, every hour of downtime represents lost production. The corresponding cost can range from 20 to up to 100 thousand euros per hour, so every minute counts.

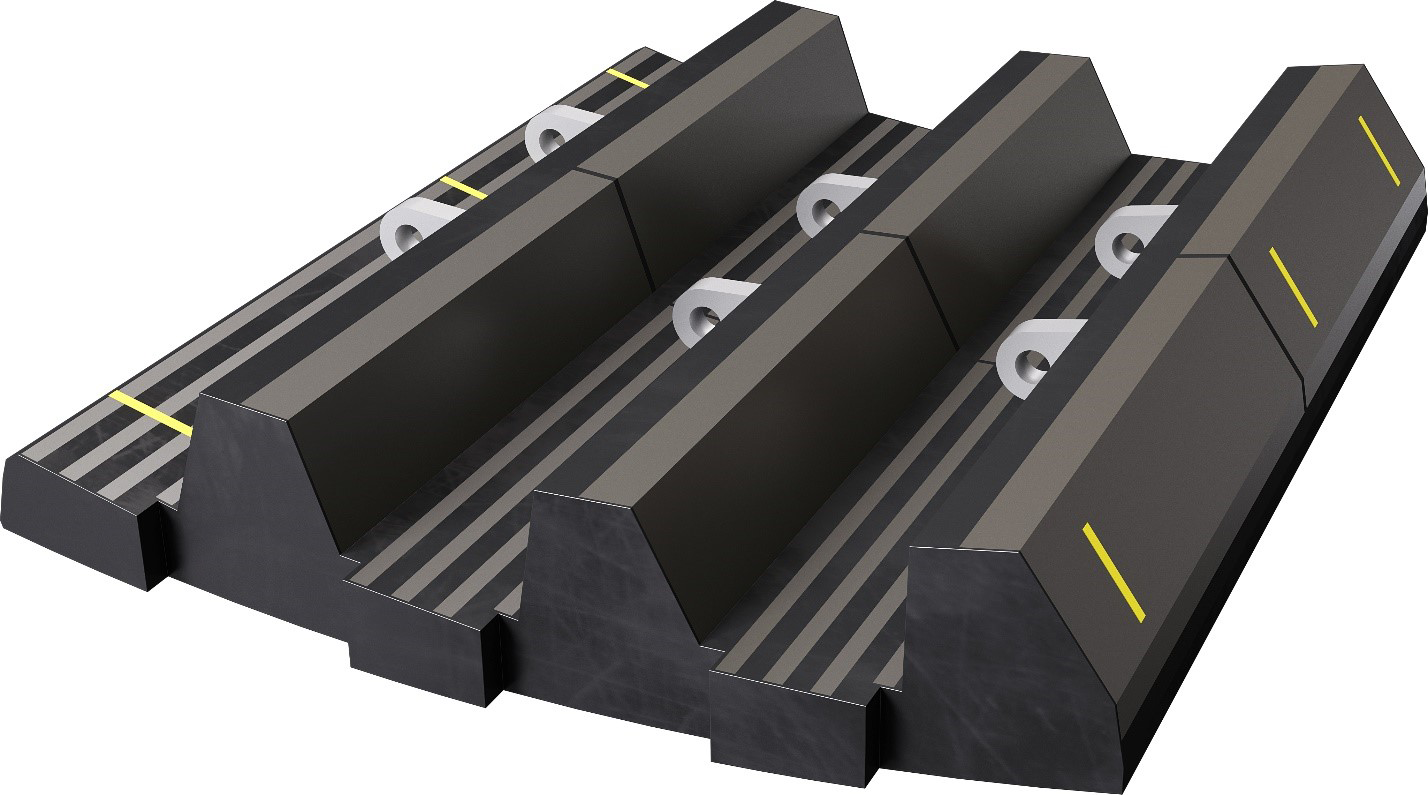

The first thing to look at is maximizing the liner size and weight. It is possible to make double liners and optimize the design layout so that the liners that are replaced most frequently are as big as possible. The logical next step is to look at alternative materials and designs. By using lighter materials, it is often possible to increase the liner size significantly without increasing the weight and thereby reducing the number of liners. MegalinerTM is a good example of product designed with this in mind. One Megaliner combines several lifter bars and plates into one simple component, making it possible to reduce the number of components to be installed by somewhere between 50 to 80%.