4. Optimized grinding mill liner design

A mill lining should be optimized by design in order to minimize problems, utilize the mill’s capacity and keep a good liner profile throughout the wear life. This can be done by maximizing the efficiency of the grinding process.

It is important to control the charge motion to ensure that as much of the impact, attribution and abrasion takes place on top of and inside the charge. If there’s too little charge motion, there won’t be enough energy to grind the ore; and if there’s too much charge motion, there’s a risk that a lot of energy turns into liner and media wear, heat and noise. If the liners are subject to direct impact, there is also a big risk of liner breakage.

As a mill liner wears, it typically becomes less profiled and at some point, it loses its capability to provide enough lift to create the correct charge motion. By optimizing the design, it is possible to minimize these effects. Our Poly-Met liner concept retains an efficient profile, similarly to metallic mill linings, as different types of wear-resistant inserts are used in combination with impact-resistant rubber.

Mill liner design trends – then and now

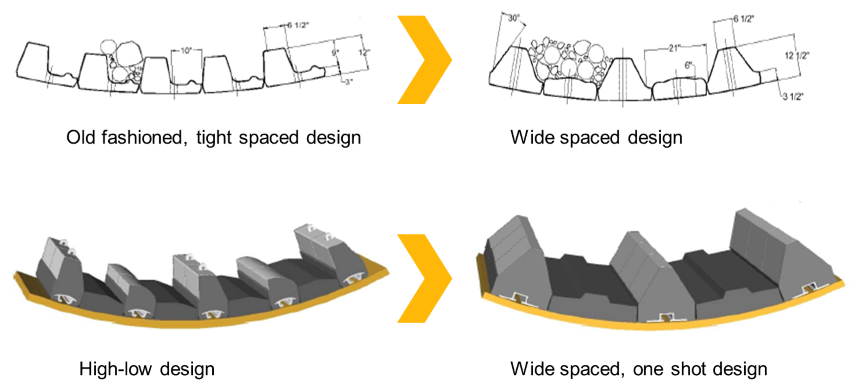

The old-fashioned high-high design of tight space, created for maximum wear life, used to be very common. But the simulation tools that are available today demonstrate that these old designs are not very efficient. They occupy too much volume, they do not agitate the charge properly, and, at the same time, they might be too aggressive and cause the charge trajectory to be too high.

The current trend is to go for a wide-space design to prevent packing and to utilize the mill volume to the highest extent possible. It is really important to make a design that promotes the optimum charge motion to prevent the liners from being impacted by the media and ore, and at the same time to make sure that the efficiency is as high as possible in order to save energy.

A high-low design is one way to improve the performance in a mill with a tight-spaced drilling pattern. However, that does require more frequent maintenance, as you need to replace every second row twice as often. A more modern design is the wide spaced, one-shot design, where everything can be replaced at the same time, minimizing the number of maintenance stops.