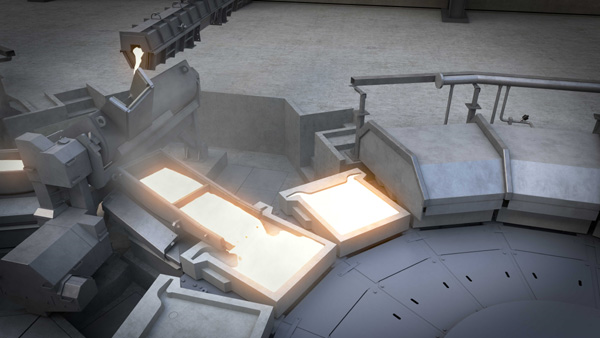

As we entered the new millennium we decided to put more effort into gradually implementing electric drives for all casting-shop movement, beginning with the most complex system, the anode collecting and handling system. Once the system had been up and running in several locations for a few years, we decided to implement electric drives in the rest of the machines – completely eliminating the need for hydraulics. To speed up the change we decided to run it as a product development project, which finished in 2015; the first hydraulic-free casting shop was commissioned in 2016. The selected components have proven to be reliable, and the feedback from our clients has been very positive.

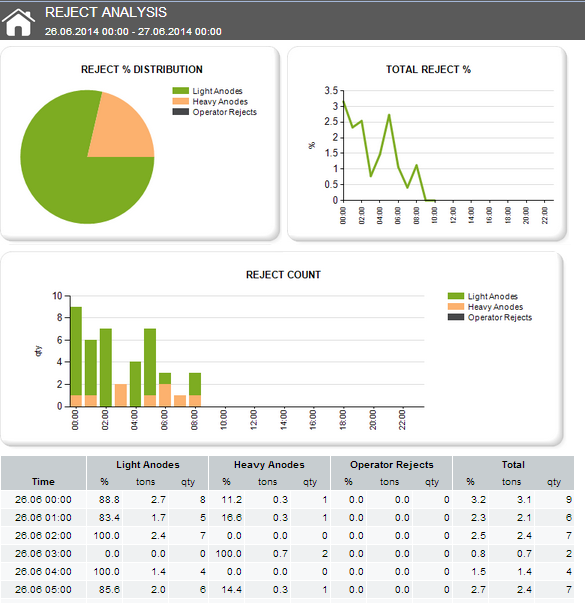

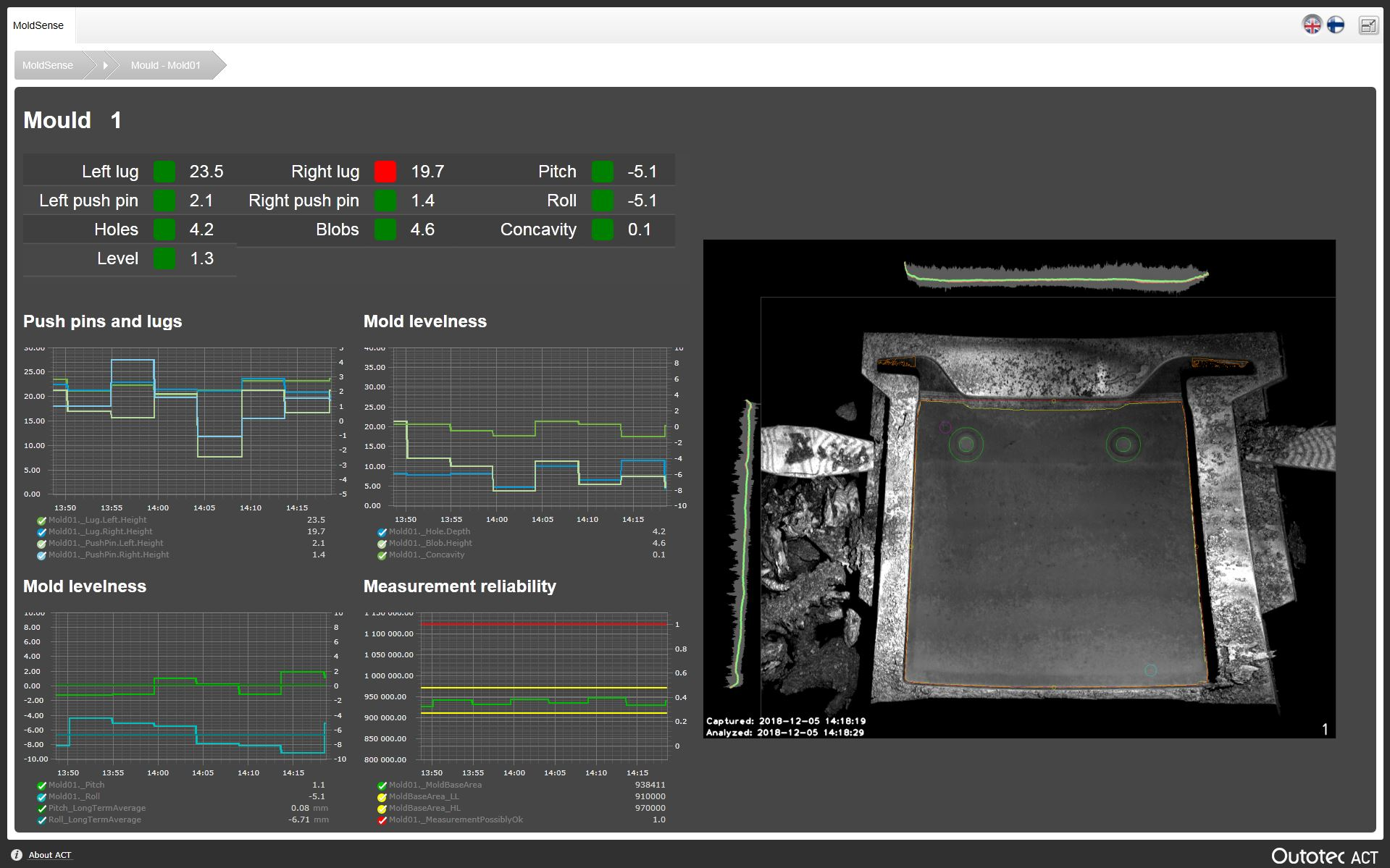

At the same time we have also developed digital products to support production monitoring and quality functions. For example, we can now supply a Casting Information Management System (CIMS) that is compatible with the Outotec Tankhouse Information Management System (TIMS); both systems are based on the Outotec ACT platform.