Grade

Low grade has a negative effect from several perspectives. The lower solids Specific Gravity (SG) dilutes the cake and requires lower cake moisture to achieve the TML. The gangue may, in the case of clays, have flake shape particles that create tighter pores, and the surface properties can have a lower wetting angle which also increases the pore pressure.

Surface chemistry

The pH required for the separation of concentrates usually means that they gave a high surface charge. This is generally detrimental to filtration, as the best results are obtained when the surface charge is minimized. Where it is not possible to change the surface chemistry, coagulants and flocculants can be effective in improving filtration rates.

Parameters which can affect filter performance

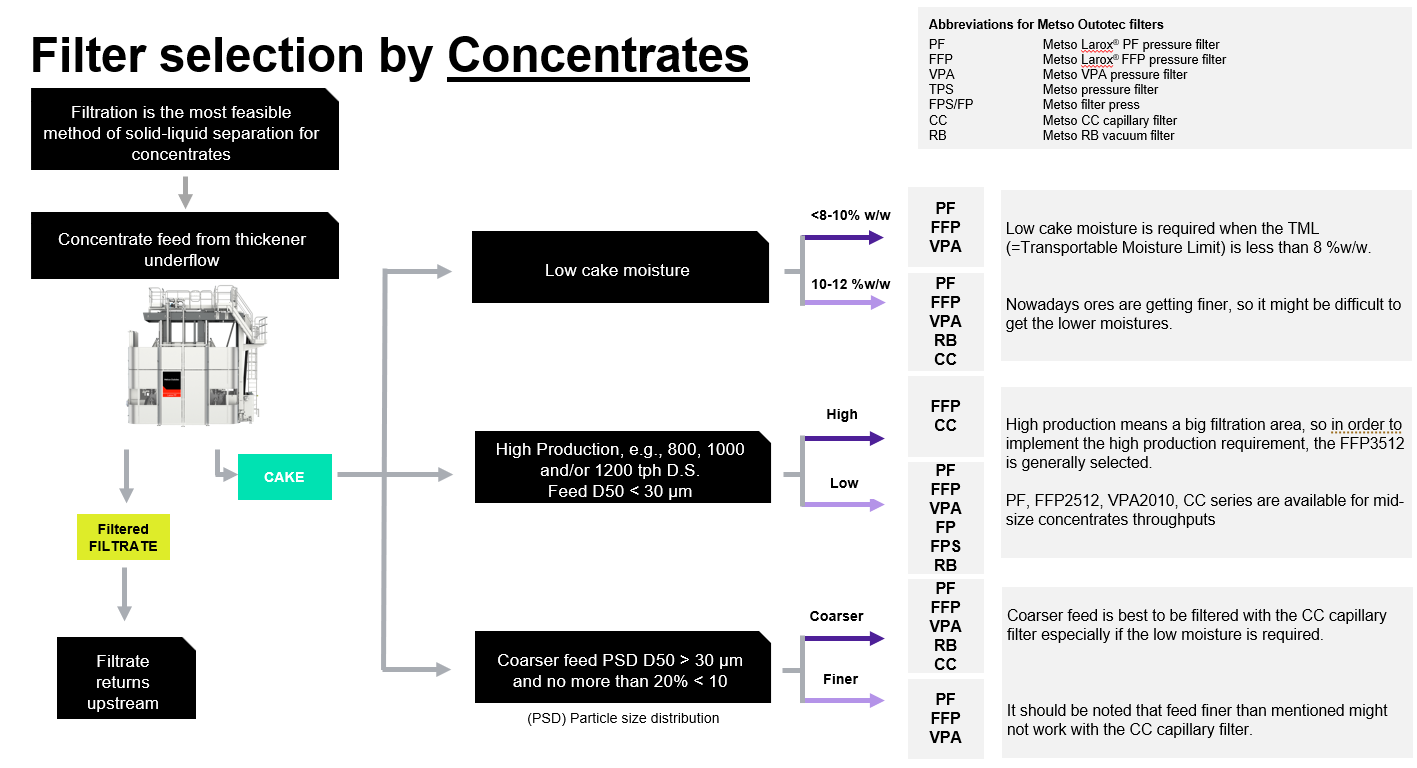

There are several parameters that will affect the filter performance, such as mechanical or operational. When the process is upstream, these process conditions have the biggest impact on the filter performance. An example of these conditions include:

-

Particle size distribution (PSD)

-

Solid content in feed

-

Mineralogy: density, shape, surface properties (stability of slurry)

-

Feed temperature

-

Liquid viscosity - composition and temperature

-

Liquid salinity - salt crystals

-

pH

-

Filter aid, e.g., diatomaceous earth, flocculants etc. (from the thickener)

These parameters, even by themselves, can significantly affect the filter results. It should also be considered that parameters such as mechanical, operational and process working together can make the biggest difference in filtration results.

During the filtration process, adjusting parameters such as times, pressure, vacuum level, belt speed, rotation speed and more can optimize filtration results.

As discussed throughout the guide, achieving the optimal moisture content in mineral concentrate filtration is essential for safe and cost-effective transportation. Metso's extensive portfolio of filtration technologies, backed by decades of industry experience, offers reliable solutions tailored to the specific needs of concentrator plants. By carefully selecting and optimizing filtration methods, plants can ensure compliance with transportable moisture limits while reducing costs and improving overall performance. That’s why, together, we are the partner for positive change.