When it comes to a successful reline, the efficiency of the event does not just revolve around the completion of the reline. There is a world of data analysis before, during, and after the reline that has now become the accepted common standard. Whether it’s calculating workflows and resources, execution tracking, end time forecasting, selecting the right mill liner, evaluating ideal scenarios and liner sequencing, or even planning for contingencies, putting in the time upfront aids in mitigating potential downtime and helps with optimization efforts.

Living in a digital world means everything can be analyzed if the right data has been collected. When the data is combined with the right expertise, improvement opportunities can be identified, and the most efficient course of action can be mapped out for ideal situation as well as for when unforeseen circumstances throw a bottleneck into the equation.

Ensuring safety during shutdown

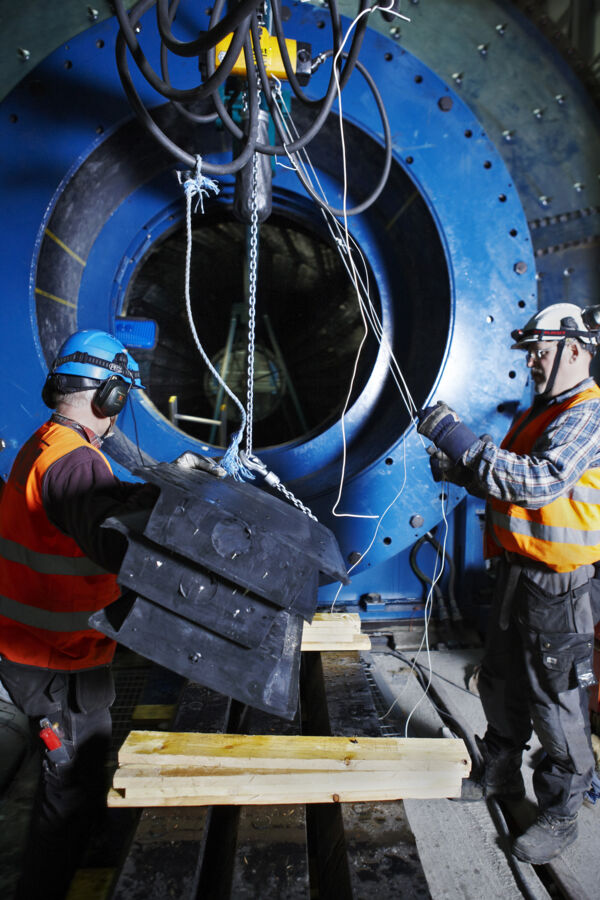

Ensuring the safety of reline crews during the shutdown process has continued to be a substantial challenge for any mine site reline. Handling and maneuvering heavy parts such as new and worn liners is a constant concern to the safety of reline crew members. Removing and handling worn mill liners requires the right tooling as well as people trained to use them in the right manner. Tool management programs and inspections are vital to ensure safety. Periodic checklist inspections, ensuring the right safety accessories, proper equipment operation, having standby tooling, and standardized crew trainings should all be fundamental activities both before and during a reline event.

One often overlooked challenge with these types of activities, is the psychological safety of the reline crew. Relining can be an extremely dangerous activity, especially if the crews are new or do not have to perform a reline frequently. Unplanned stops due to safety issues or an accident can be costly for both the mine and the personnel, which is why companies often focus their attention on identifying how accidents can be either fully prevented or how their effects can be mitigated if something unforeseen were to occur. Solutions vary from having experts in designated positions and cross training with new technicians to engaging in regular safety conversations to maintain and reinforce safety. In these types of situations, where every minute counts, continuing to monitor the surrounding environment as well as evaluating the mental health of the reline crews, all help ensure personnel are sent home without running into harm.