2. Critical path maintenance – the rotable hopper

Some of the challenges experienced in COS feeder hopper maintenance include duration, safety, pre-planning and execution. Incorporating a rotable feeder hopper strategy allows for simplified and safe lift-in/lift-out maintenance of the COS feeders.

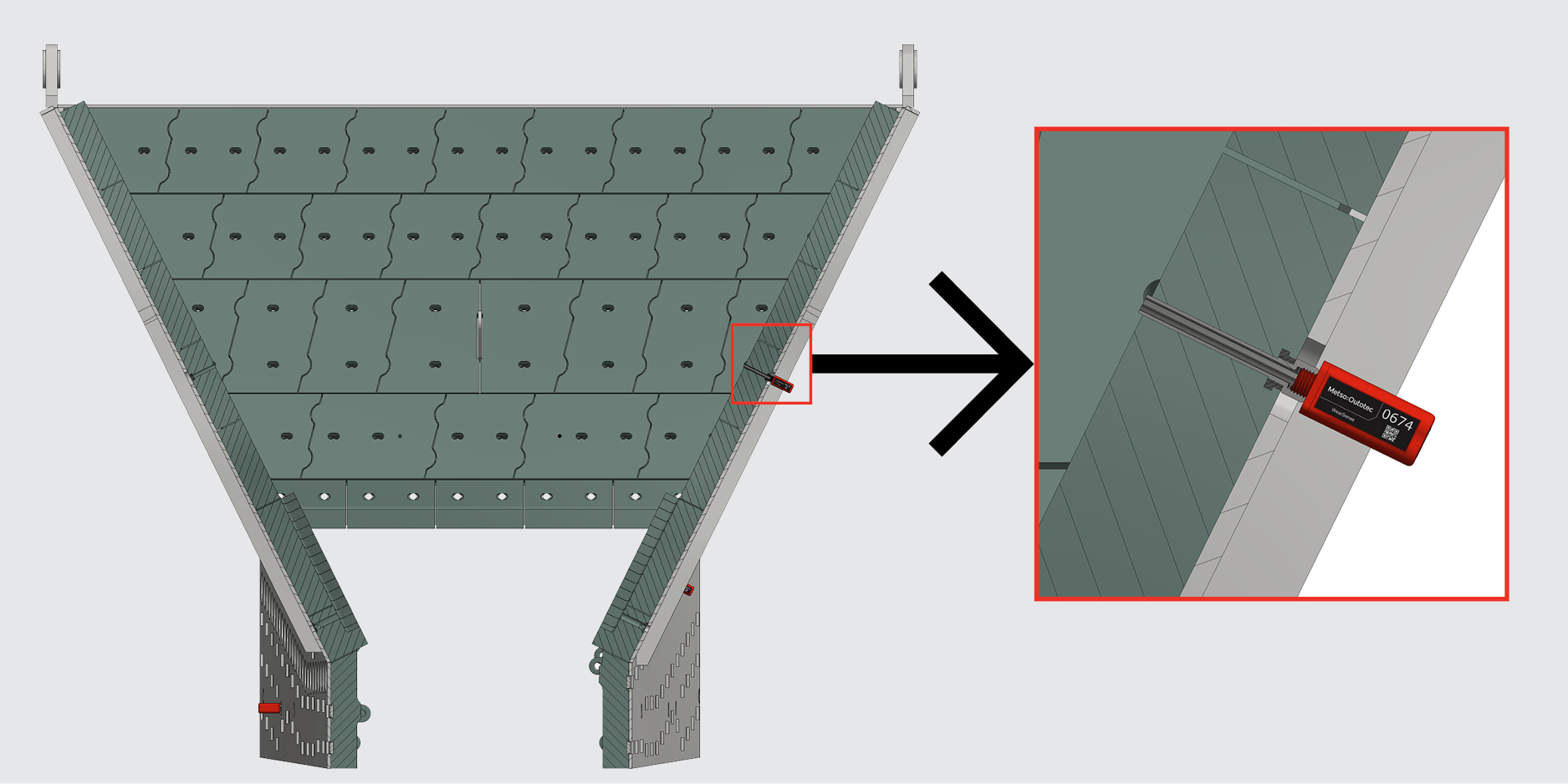

Metso Outotec rotable hoppers are custom designed to a site’s parent asset requirements. The hoppers use a range of support mechanisms, from self-supporting beam section mounting, through to low profile internal tab support systems. Each rotable hopper is designed to support a site’s maintenance strategy, taking into account factors such as required wear life, shutdown durations and preference for full or partial relines. Options range from heavy-duty reusable tubs to enable continuous rotation through to light weight, lower-cost, single-use structures.

A rotable strategy allows for a simple lift-in/lift-out process post the first installation, therefore not only greatly reducing the scope of work in subsequent maintenance shutdowns but also reducing safety exposures to the maintenance team. A rotable strategy ensures minimized run down and ramp up, allowing for closer alignment to the shutdown durations of other critical path assets and increasing overall production up-time.