Often, the first thing that comes to mind in terms of wear parts are the working wears. These require regular changeouts as they come into direct contact with the rock or ore. Moreover, choosing the right wear parts or liners can enhance the crusher’s efficiency and directly impact the quality and size of the end-product.

A holistic approach to crusher wear parts

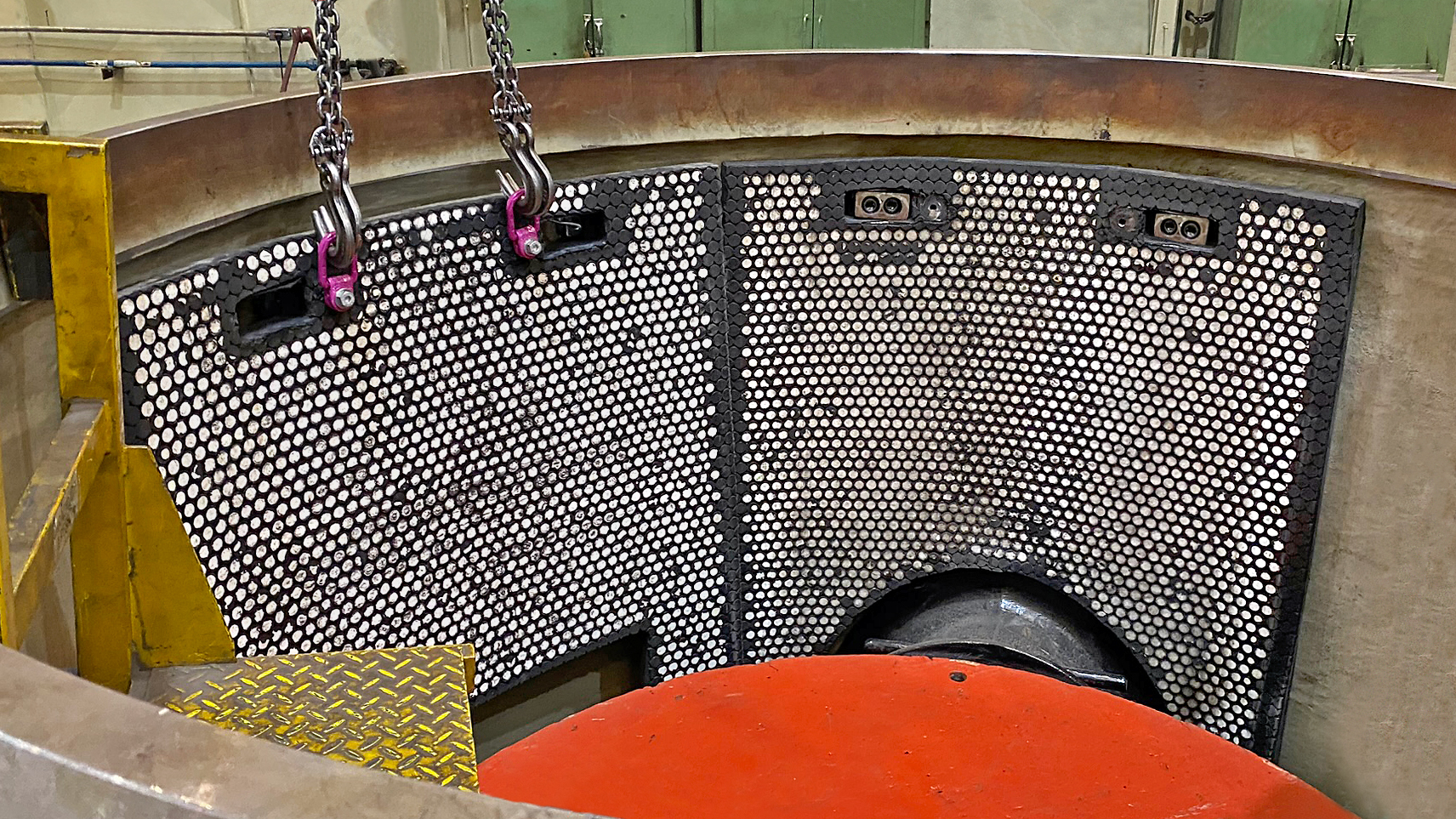

Working wears are not the only consideration – protective wears also can be consequential in your operation and in protecting your crusher. Protective wear parts, which can shield important parts of the crusher such as the mainframe or access, can sometimes be an afterthought. Makeshift fixes may come into play: “This may not last a full cycle, but it will have to do for now” can be a trap to fall into when it comes to protective wears.

However, a more proactive approach to protective wears, in tandem with working wears, can be beneficial. Standard options are available, including the abrasion-resistant steel mainframe liners and cast steel armguards. However, high-wear solutions such as Metso Poly-Cer protective wears can bring maximum benefits and protection for your crusher.