Obuasi BIOX Recommissioning

The commissioning of the Obuasi BIOX plant in 1994 was a major milestone for the BIOX process, confirming both its scalability and its suitability for operating in remote locations. The Obuasi Mine was placed on limited operations towards the end of 2014, and on care and maintenance from 2016.

In June 2018 the Parliament of Ghana ratified the regulatory and fiscal agreements that cover the redevelopment of the mine and the Environmental Protection Agency issued environmental permits. With the key permitting and regulatory processes finalized, the mining services contract could be signed as another key milestone in delivering a modern, mechanized underground mining operation with 5.8M oz of ore reserves and 34M oz in mineral resources, and a mine lifetime extending over 20 years.

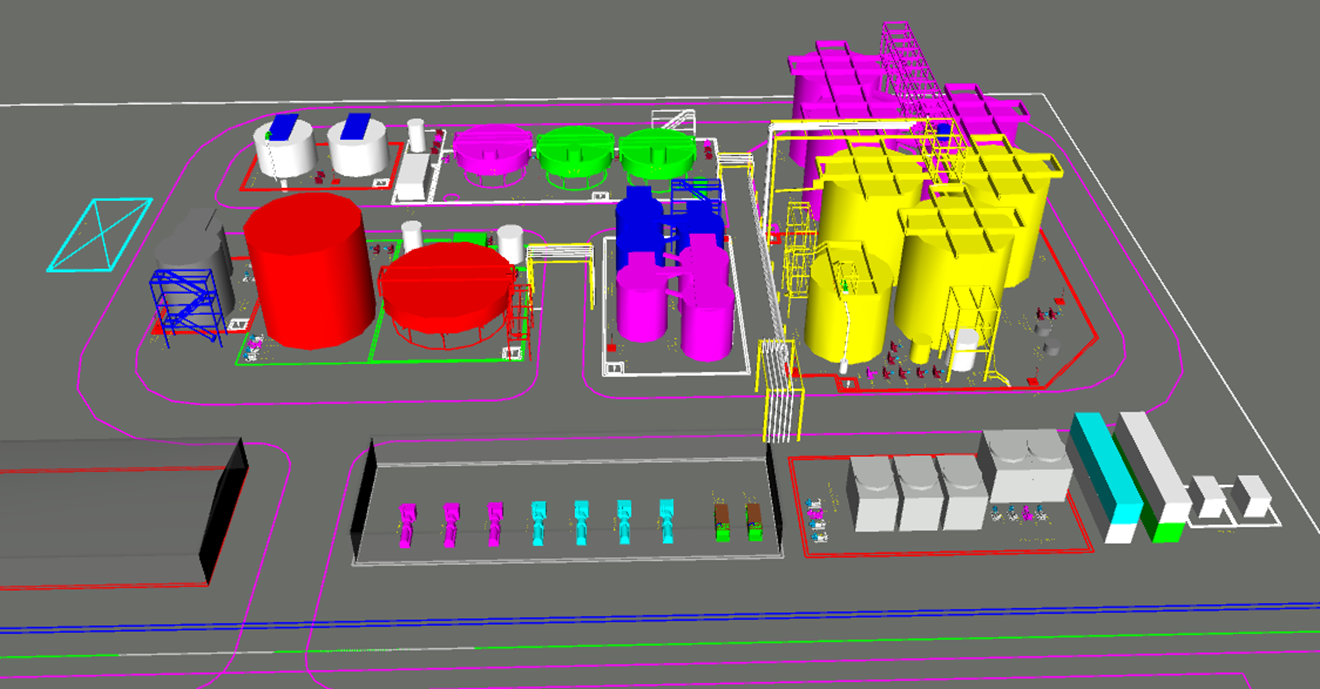

Following receipt of all the requisite approvals from the Ghanaian government, including parliamentary ratification and environmental approvals in June 2018, redevelopment of the Obuasi high-grade ore body has started in earnest. The first blast took place in February 2019 with the first gold production scheduled for the end of 2019. The initial production rate will be 2,000 tpd (ROM)ore for the first 12 months; production is expected to reach 4,000 tpd by the end of 2020 and ramp up to an ultimate capacity of 5,000 tpd. Annual production is expected to average 350,000–450,000 oz at an average head grade of 8.1 g/t for the first 10 years.

Fosterville ASTER Plant

The Fosterville mine is a high-grade, low-cost underground gold mine located 20 km from the city of Bendigo in the State of Victoria, Australia. The current operation was commissioned in 2005 and includes a BIOX plant. In 2010 Fosterville commissioned the first HiTeCC plant, developed by the mine technical team, for the mitigation of the preg-robbing associated with the treatment of the Fosterville ores.

Fosterville has been evaluating the implementation of the Outotec ASTER process for a number of years to improve the mine water balance by allowing treatment and then recycling of tailings dam water back into the process. In 2019 Fosterville decided to continue with the implementation of the ASTER plant, which will be the fourth application of ASTER technology.

The plant will have a design capacity of 792 m3/d of solution with the predicted thiocyanate and cyanide concentrations at 5,000 ppm and < 10 ppm respectively. The plant will consist of four ASTER tanks, each with a design volume of 225 m3, followed by a static settler to produce a clear product solution to feed to the plant process water and a thickened sludge underflow that can be recycled to the primary ASTER reactors.

Construction of the plant is well under way and commissioning is expected to take place in early 2020.