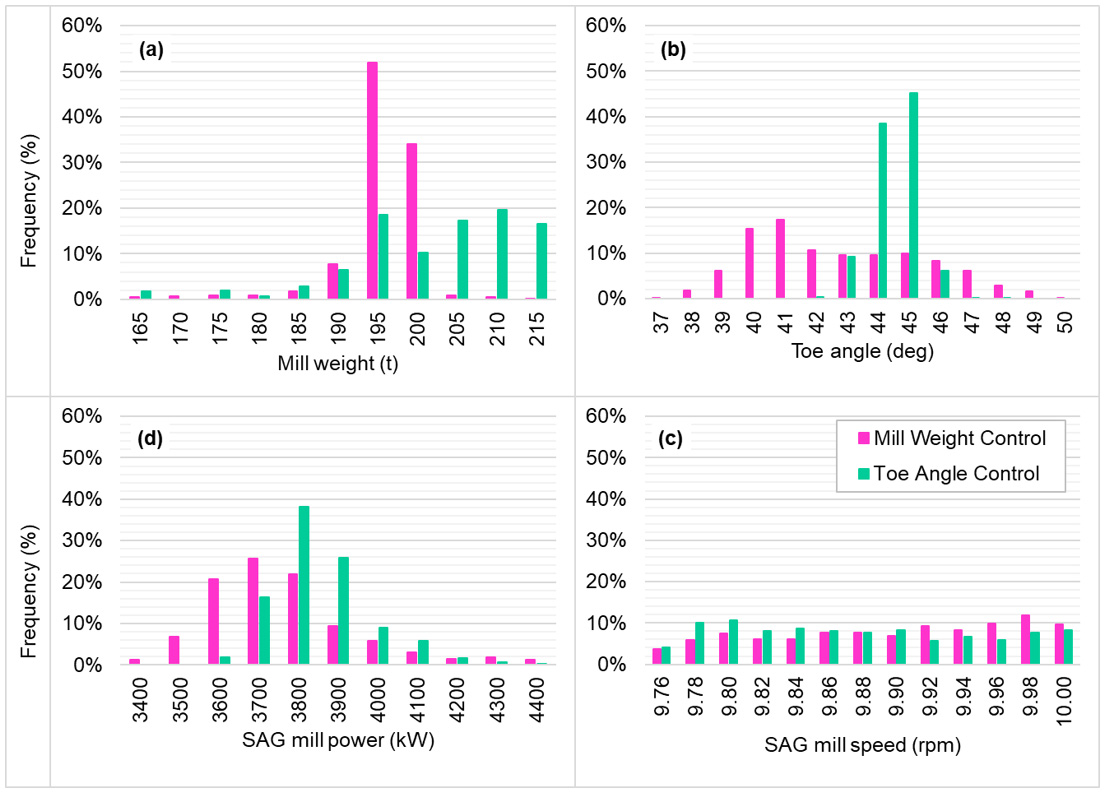

Figures 9(a) and (b) show that both weight and toe angle control strategies achieved a comparable distribution of each controlled variable to its respective set point. Notable is that a narrow weight distribution did not result in a narrow toe angle distribution (and vice versa), highlighting the drifting nature of the weight signal. Further, the power histogram, Figure 9(d), developed during the toe angle control trial presented a more defined, narrower peak than that developed during the weight control period. Given that a reasonably consistent speed distribution (Figure 9(c)) exists between the two compared data sets, it was assessed that a narrower distribution of SAG mill volumetric filling was achieved when the SAG mill was operated toe angle control in comparison to the incumbent weight control.

Conclusions

Initial results indicate that toe angle control has delivered a benefit to Lihir process control by being repeatable measurement, consistent through process interruptions and independent of mill liner wear. Quantifiable production improvements were not available at the time of writing, but improved control of volumetric filling was achieved and reduced the risk of further mill overload events was realized by the implementation of toe angle control on the HGO1 SAG mill.

Acknowledgements

This article is based on the ‘Toe angle measurement for SAG mill control at Lihir gold mine’ paper presented at the AusIMM Mill Operators’ Conference, August 29-31, 2018. The authors of the conference paper are listed below. The contributions of the Lihir metallurgy, operations, instrumentation and process control teams provided valuable feedback and assistance throughout the development and implementation of MillSense. Without their collective contributions the success of this installation would not have been achieved.

F Burns1, C Aisthorpe2, P Blanz3, M Randall4, P Ebzery5

1. Senior Metallurgist – Plant Optimisation, Lihir Gold Mine, Newcrest Mining Limited.

2. MAusIMM, Senior Metallurgist – Plant Optimisation, Lihir Gold Mine, Newcrest Mining Limited

3. Product Manager – Advanced Process Control, Outotec.

4. Senior Metallurgist – Process Control, Lihir Gold Mine, Newcrest Mining Limited

5. Specialist – Process Control, Lihir Gold Mine, Newcrest Mining Limited

References

Baas, D, Bennett, D, Walker, P 2014. Developing process control standards for optimal plant performance at PanAust Limited, 12th AusIMM Mill Operators’ Conference, pp. 325-334.

Karageorgos, J, Genovese, P, Baas, D 2006. Current trends in SAG and AG Mill Operability and Control, SAG 2006.

Ketcham, V J, O’Reilly, J F and Vardill, W D 1993. The Lihir Gold project: Process plant design, Minerals Engineering, 6(8-10)1037.

Napier-Munn, T.J 2009. An Introduction to Comparative Statistics and Experimental Design for Minerals Engineers (2nd Edition), Julius Kruttschnitt Mineral Research Centre, University of Queensland.

Napier-Munn, T.J, Morrell, S, Morrison, R.D, Kojovic, T 1999. Mineral Comminution Circuits: Their Operation and Optimisation, Julius Kruttschnitt Mineral Research Centre, University of Queensland.

Newcrest Mining Limited, 2017a, 2017 Annual Report, 09 October 2017.

Newcrest Mining Limited, 2017b, September 2017 Quarterly Report, 26 October 2017.

Noble, A, Clark, A and Akis, D 2009. Lihir Gold Limited – A Large Step Forward for the Lihir Gold Mine, 10th AusIMM Mill Operators’ Conference, pp 1-6.

Powell, M, Toor, A 2006. Extended grinding curves are essential to the comparison of milling performance, Minerals Engineering Vol. 19, Issue 15, December 2006, pp. 1487-1494.

Powell, M.S, van der Westhuizen, A.P, Mainza, A.N 2009. Applying grindcurves to mill operation and optimisation,

Minerals Engineering Vol. 22, Issue 7-8, June-July 2009, pp. 625-632.

Ruel, M 2013. Fuzzy Logic Control On a SAG mill, 16th IFAC Symposium on Automation in Mining, Mineral and Metal

Processing, pp. 282-287.

Smith, G. C, Jordaan, L, Singh, A, Vandayar, V, Smith V.C, Muller B and Hulbert D.G 2004. Innovative process control

technology for milling and flotation circuit operations, The Journal of The South African Institute of Mining and

Metallurgy, Vol. May 2004, pp 353-366.

Toor, P 2015. Optimisation of a Semi-autogenous Grinding Mill through Trajectory and Power Modelling, MetPlant 2015.