Modifications and Improvements

The most important modifications and improvements, including process control, maintenance practices, as well as the environmental issues, are given below:

- Increase of preheating enriched air capacity up to 230ºC.

- 100% refractory relining (hearth included) and new FSF cooling elements.

- Waste Heat Boiler (WHB) modifications.

Regarding energy consumption, a new preheater for process air was installed in order to increase the temperature of process air from 135ºC to 230ºC. The preheater is heated by high pressure steam (40bar). In addition to energy consumption, the higher temperature of process air will be also used to increase or decrease the amount of enriched air in the concentrate burner.

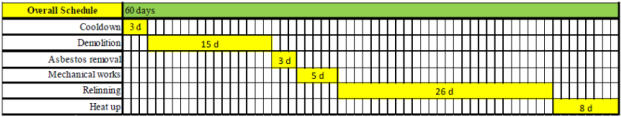

Despite energy savings, another important factor in smelter operation is the efficiency of the process. Thus, in order to improve the efficiency of the process, the hearth of flash furnace was relined, after being in use for 38 years.

Two main improvements were included. The first was the introduction of a third 150 mm magnesia-chrome brick refractory layer to reinforce the hearth. The second improvement was the replacement of the isolating concrete by additional clay bricks, in order to avoid any risk arising from insufficient curing of concrete during the FSF warm up. In addition, the uptake shaft arched roof was changed to a flat roof design.

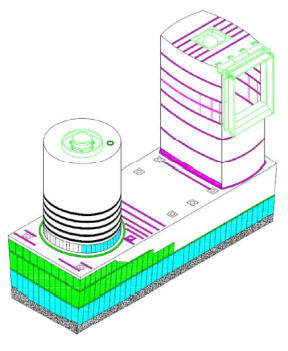

As the critical point in the operation of the FSF is the water cooling system, several modifications and improvements have been made to extend the furnace brick life. Thus, first,with Outotec recommendation, the thickness of the cooling elements in the settler under the reaction shaft has been increased from 70mm to 115mm, in order to avoid some detected problems like bending and leakage during the last campaign. Second, in order to reinforce the cooling capacity, in the areas where high wear was measured during the last campaign, 70 new cooling elements have been installed (Figure 2). Consequently, the whole cooling water system including a new cooling tower, new pumps, and emergency systems was needed to review in order to ensure proper cooling capacity.