Flotation circuits are typically controlled using on-line elemental assays obtained from the slurry lines. In base metal applications this analysis is typically performed using centralized XRF analyzers. Outotec solutions based on XRF technology include Courier 5 and Courier 6 analyzers.

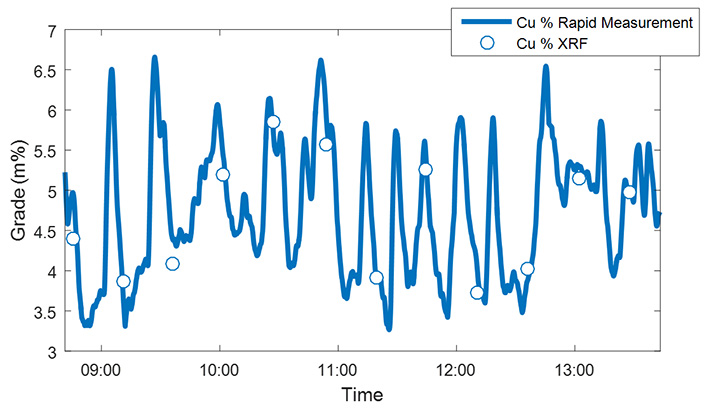

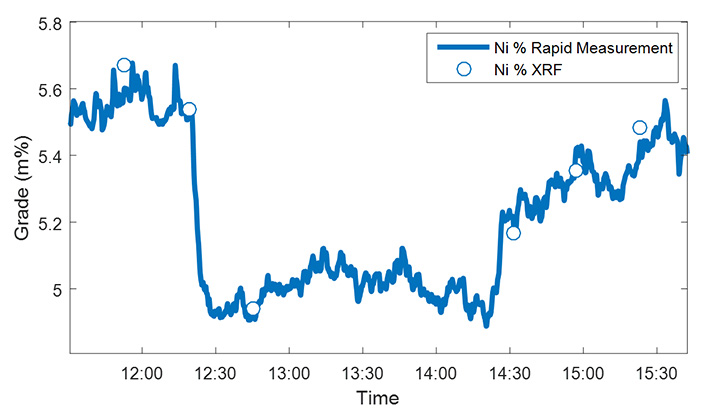

Reflectance spectroscopy, on the other hand, is an emerging technique that is used to obtain more frequent measurements from slurries. It is especially beneficial in rougher and final concentrate streams where grades are on a suitable level to allow accurate measurement. With reflectance spectroscopy, the sampling interval of the elemental assays can be radically reduced. When this measurement option is included in the Courier line, the typical sampling interval of 10 to 25 minutes is reduced to just 10 seconds. This virtually continuous assay information reveals rapid changes in grades and improves the performance of automatic process control solutions.

Reflectance spectrum measurement

Reflectance spectrum measurement is based on the mineral-specific absorbance of light in the visible and near-infrared (VNIR) wavelength range. Because the system is relatively inexpensive and simple, it is possible to measure simultaneously in several slurry lines with a very short sampling interval. However, the information contained in the VNIR spectrum is difficult to interpret, and the spectrum is also affected by other slurry properties. As a result, the rapid reflectance spectrum analysis needs to be regularly calibrated using an XRF analyzer.

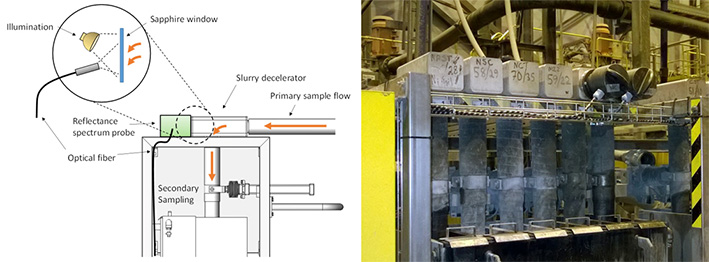

The rapid measurement device consists of measurement probes installed in the secondary sampler of the Courier multiplexer unit, and an analyzer unit attached to the side of the multiplexer. Due to the centralized structure of the Courier analyzer, all the important slurry lines are available for practically continuous reflectance spectrum measurement. The structure of a typical installation is shown in Figure 1.