The Suzdal mine is located 55 km southwest of the city of Semey (formerly Semipalatinsk) and since 2005 has utilized Outotec’s BIOX® technology to pre-treat its refractory sulfide ore body. The ore body is a well-known double-refractory ore with both visible and invisible gold hosted in sulfide associations of pyrite and arsenopyrite as well as carbonaceous black shale.

Suzdal operates an underground mine feeding a processing plant with crushing, grinding, flotation, BIOX, CCD, and CIL circuits. The plant operates three proprietary Outotec technologies used in the treatment of refractory gold ore:

- The BIOX process developed for the pre-treatment of refractory gold concentrates; the Suzdal BIOX plant was commissioned in 2005 and was the first implementation of this process in Eurasia.

- The ASTER™ process is a biological process for the destruction of cyanide and thiocyanate in leach residue solutions, allowing for the recycling or disposal of the detoxified solution; the Suzdal ASTER plant was commissioned in 2013 and improved water management at the mine.

- The HiTeCC process was developed for the recovery of preg-robbed gold from leach residues; the Suzdal HiTeCC plant was commissioned in 2016.

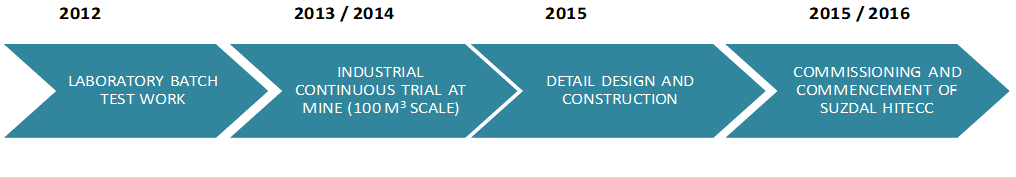

Metallurgical test work was done by the Suzdal technical team under the direction of Outotec BIOX process specialists and included laboratory and semi-commercial tests. The tests confirmed that between 40 and 70% additional gold recovery could be achieved from both current and historical tailings.

The project was approved in 2015 and the detailed design completed in December 2015. The key design criteria for the Suzdal HiTeCC plant are shown in the table below. The circuit design allows for the re-treatment of old tailings material and fresh leach tailings at a combined rate of 130,000 tpa. Construction of the facility was started in July 2015 and commissioning completed in June 2016.

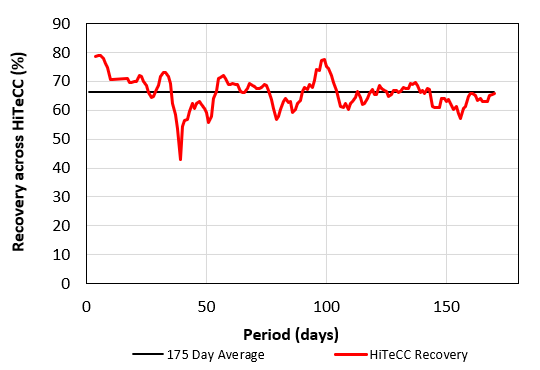

The Suzdal HiTeCC plant has been operating well and has consistently achieved recoveries within the specified design range. Figure 1 below shows HiTeCC recoveries achieved over a 175-day period.

Nordgold invested USD 5.8 million in the construction of the state-of-the-art HiTeCC facility, expecting a full return on investment in less than 20 months (assuming a gold price of USD 1,200/oz and an exchange rate of 350 KZT/USD). The facility is expected to increase production output at Suzdal by between 9 and 14 koz of gold doré per year for 10 years and the HiTeCC life-of-mine AISC is expected to be approximately USD 420 per ounce.

Nikolai Zelenski, CEO of Nordgold: “The launch of HiTeCC is an important technical milestone for Nordgold as it highlights our strategy of pursuing operational excellence. Suzdal is a long-time pioneer in the implementation of the best and most innovative operating solutions, and we are proud that the mine is only the second in the world to launch this technology, which will have very real financial benefits for the company in terms of both extending the life of mine and increasing production. The launch of the new gold recovery circuit using innovative HiTeCC technology is yet another confirmation of Suzdal's leadership as a high-technology gold producer in CIS.”