An inching drive, what is it and why is it needed?

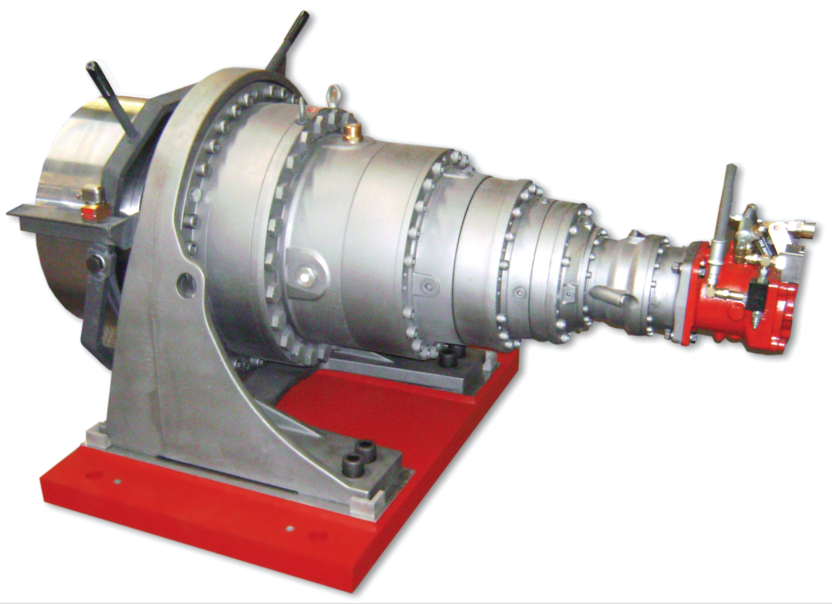

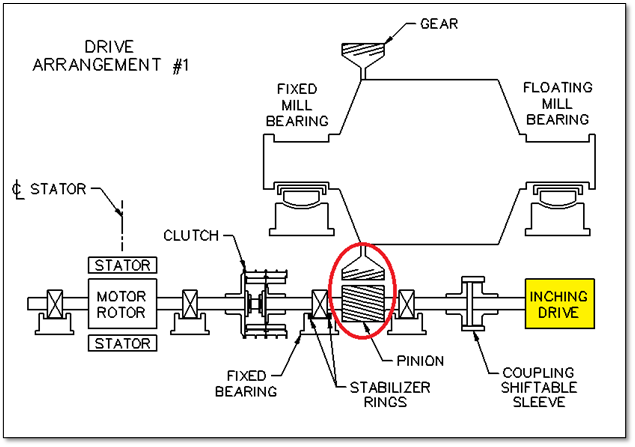

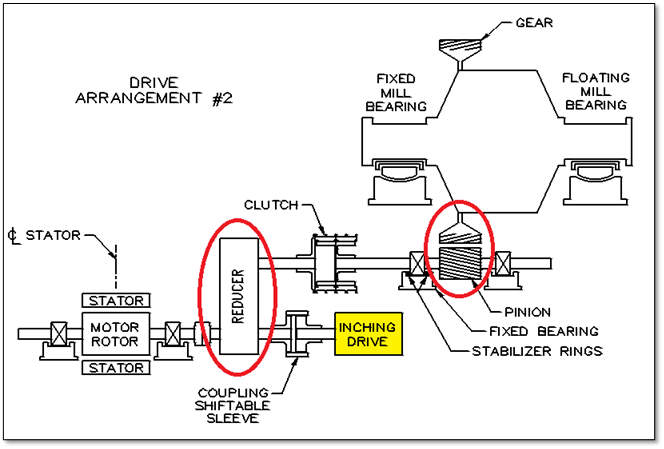

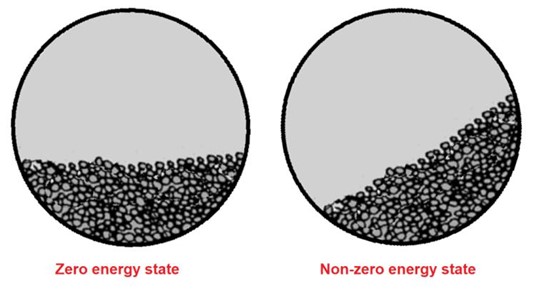

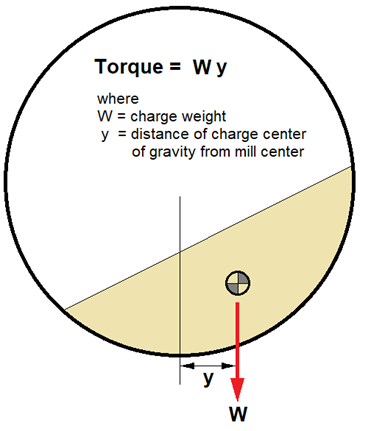

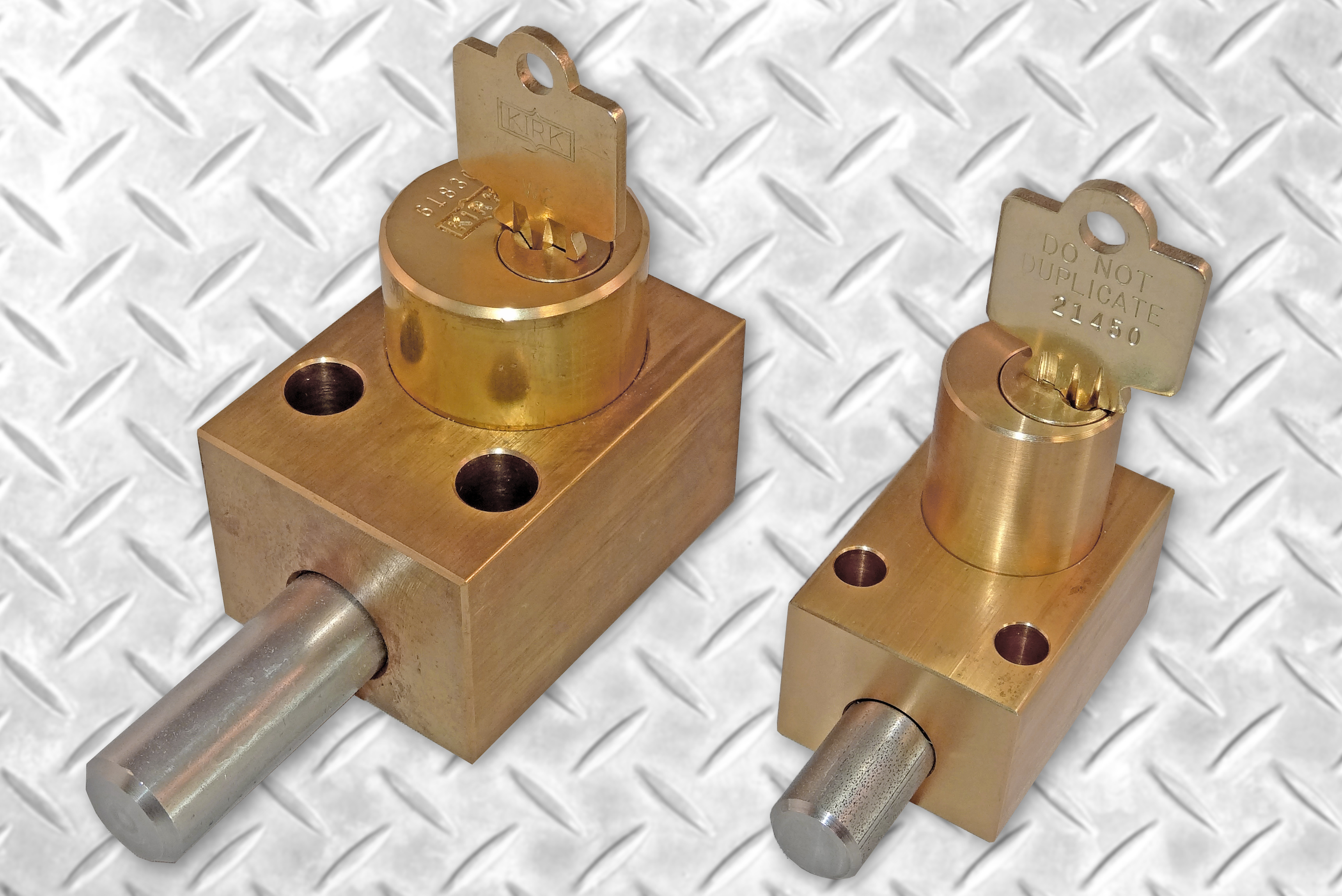

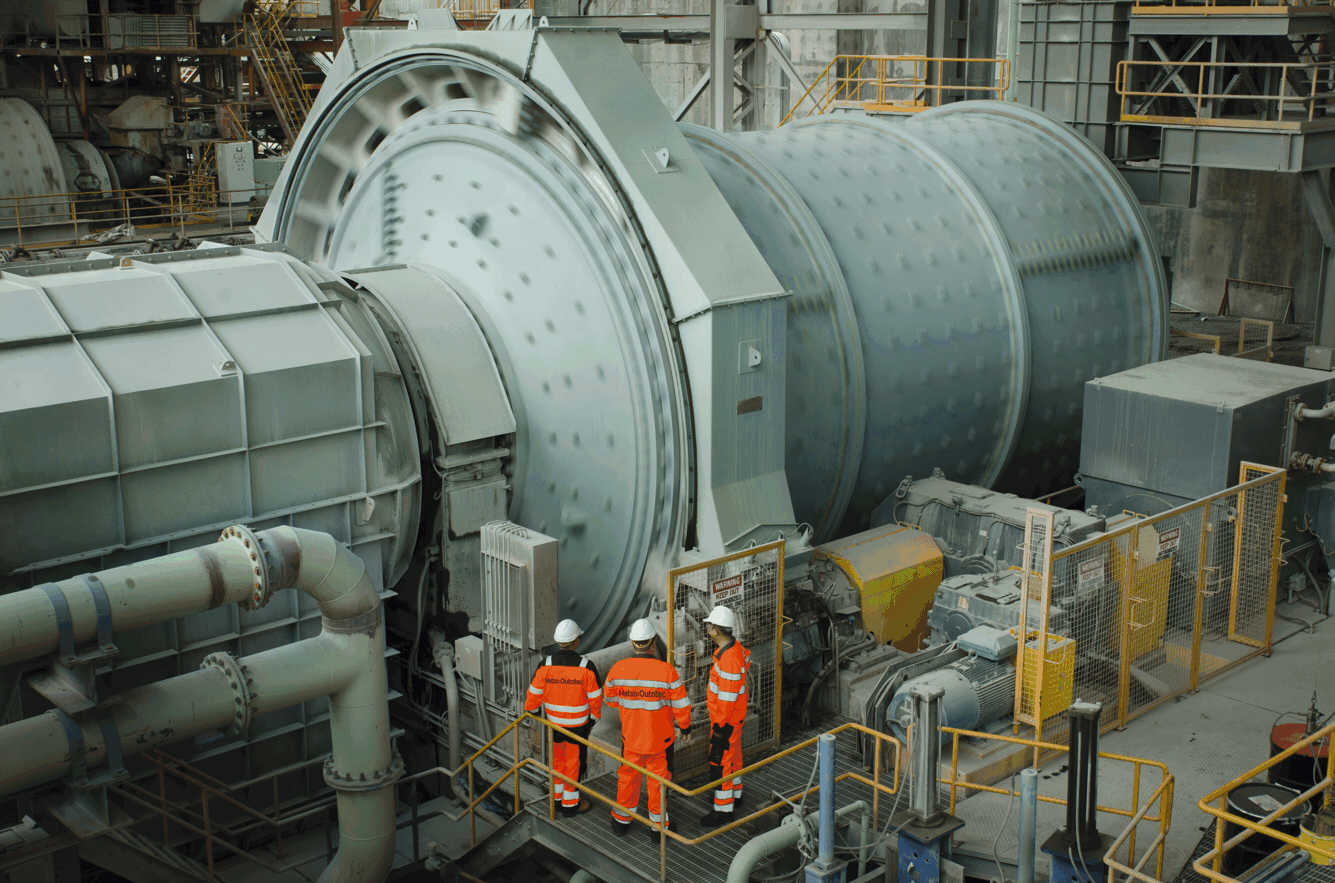

Grinding mills are typically designed for long life (minimum 20 to 25 years). It is not uncommon to see grinding mills still operating today with an age of 2-3 times their original intended lives. This is only possible with regular inspections and maintenance, which involves replacing normal wear items such as liners that protect the rotating structure, as well as replacing gears and pinions. Such inspections and maintenance require stopping the mill and turning the mill at very low speeds to the desired mill position. The main mill motors generally cannot be used for turning the mill at these low speeds. These motors may also not be available if they are being serviced at the same time. In such situations, we require auxiliary drives such as inching drives equipped with brakes so that the mill can be positioned and locked to allow personnel to safely enter the mill to perform their inspections or service work

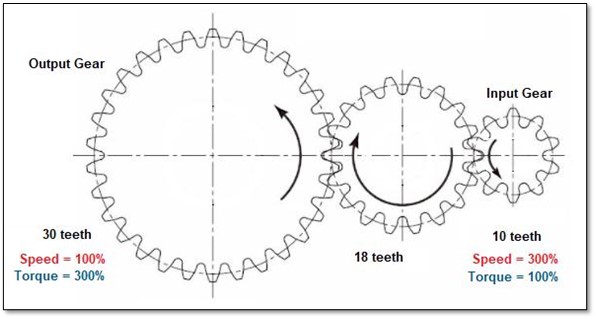

A large mill could be rotating at 10 to 15 RPM, depending on its size, during normal operation, yet an inching speed of about 1% of operating mill speed (i.e., 0.1 to 0.15 RPM) is sufficient to position the mill. Inching drives can be equipped with hydraulic or electro-mechanical motors.