Even excavator buckets have been used to remove screening media from screens

Overall, steel tensioned screens pose the most risk to operators and maintenance technicians. First, because they are generally larger, heavier, and less ergonomic pieces.

Screening media can weigh more than 100 kg each and require more than one person to be disassembled and removed from the screens. It should also be remembered that very often these operations have to be carried out in confined areas.

Precisely because they are heavy, these one-piece parts need to be moved with the help of external equipment.

Sometimes maintenance engineers resort to using excavator buckets to remove worn-out screening media with new screening media, in the case of steel tensioned screens. In addition, it should be remembered that screens generally have more than one deck and that changing screens on the second or third deck, for example, requires removing the upper layers, doubling the level of risk exposure.

Replacement, under these conditions, takes four to eight hours and includes everything from removing the worn media to screwing in the new ones. The removal of screws in old wire screening media frequently requires the use of a blowtorch due to the wear of the parts – a further source of risk.

Heavy wear can also create sharp edges on metal components, which creates the possibility of incidents such as cuts.

Due to so much exposure to risks, quarries, in general, have safety protocols for the exchange of wire mesh, from the use of appropriate personal protective equipment (PPE) to the training of the workforce that performs this operation.

The exchange routine also favors the use of external equipment such as backhoes as aids in moving heavy parts.

Screening media: rubber reduces exposure to risks when changing parts

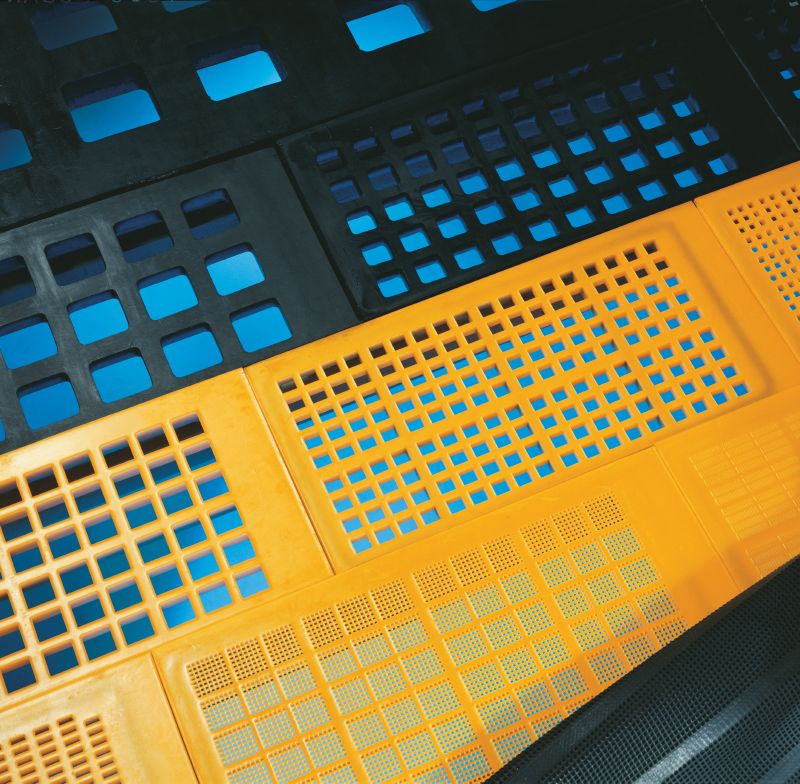

Another alternative that significantly increases safety in quarries is the adoption of rubber or hybrid screens – rubber and steel – for screens.

Modular parts help facilitate screening media changes, as they weigh between 4 kg and 20 kg. This allows only the areas of effective wear to be exchanged. An operator only has to move individual modules which each weigh less. With this, the maintenance time is reduced: the exchange of a module takes an average of 5 minutes.

The most modern quick-change systems also simplify the process, avoiding the use of screws, hammers, and in extreme cases blowtorches.

Finally, to ensure risks are minimized, it is important to constantly train the workforce on how to operate and maintain screens safely, and regularly consult with suppliers to evaluate the whole screening process.