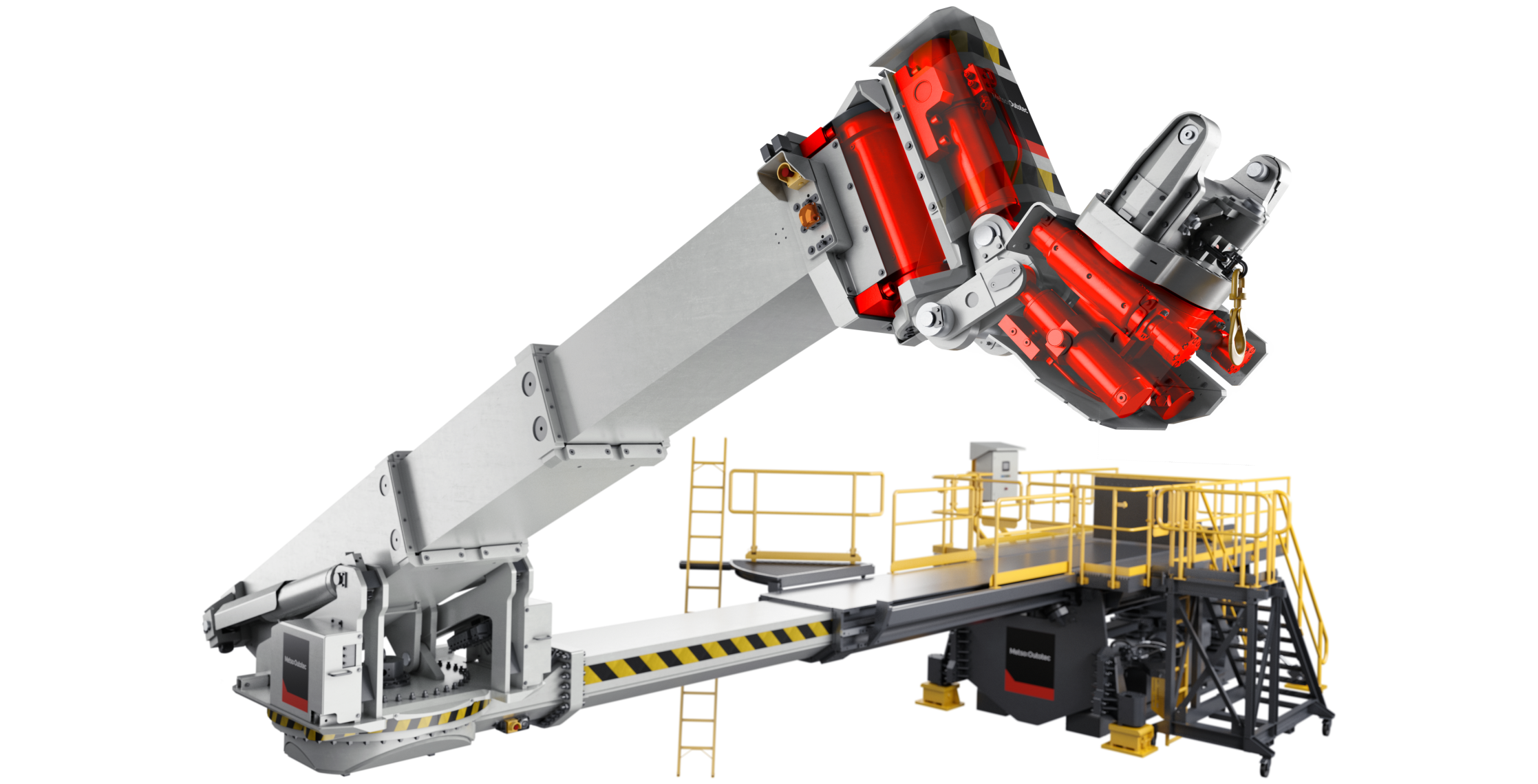

The ever-present push for more efficient relining has generated significant mechanical advances over the past few decades, resulting in tangible improvements to both relining speed and safety. However, the limits of these mechanical improvements are starting to become evident and a new frontier is emerging – Digitalization. Sensors, networks, remote connections, data analysis, process modelling and automation are the new opportunities for relining advancements.

Automation is perhaps the most attractive item on the digitalization list. The mill relining environment is infamous for being dangerous and fatiguing, so the desire to utilize automation to remove people from this environment is obvious. However, the strategy with which to approach automation is vitally important and lessons can be learned from other industries that have already blazed the automation trail.

There are three main options on the table:

-

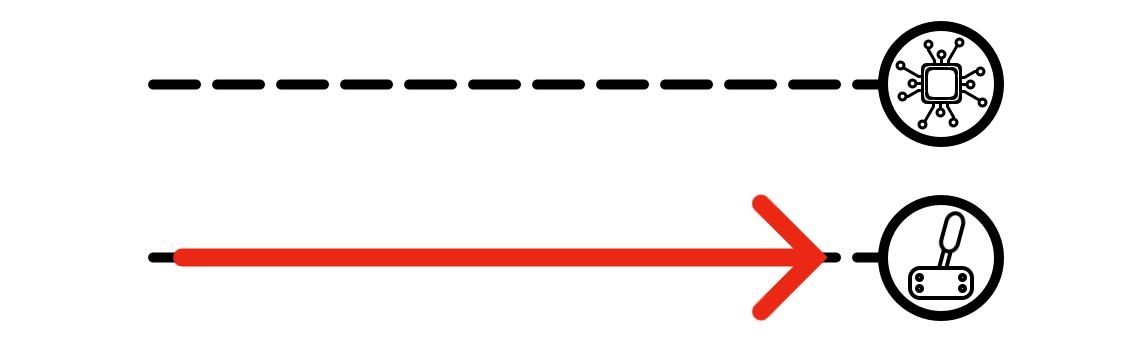

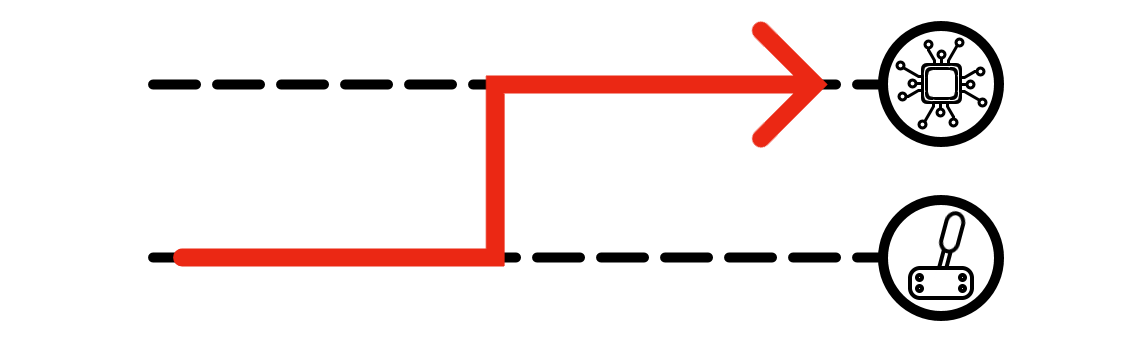

Do nothing – Assume that current designs will not quickly lose relevance

-

Step change – Commit to a complete autonomous revolution

-

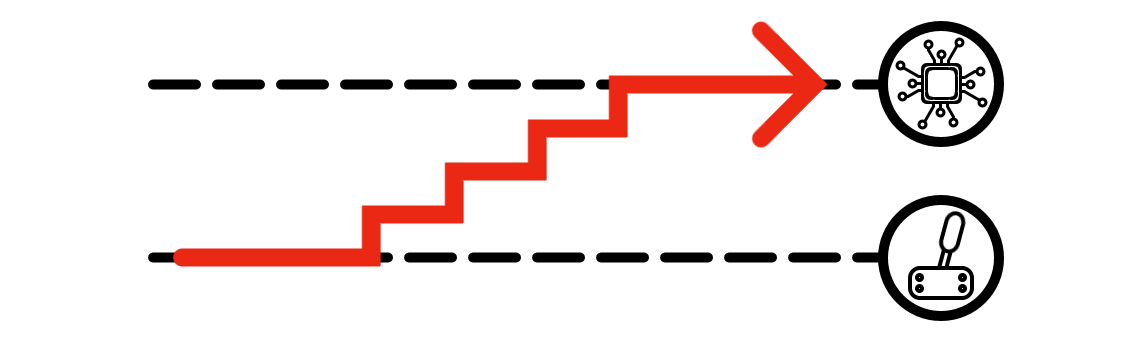

Incremental change – Search for incremental benefits with discrete value

The mining industry is constantly evolving, so each approach comes with significant risks. However, by exploring the options, it quickly becomes evident that one of the approaches is far more suited to mill relining than the others.