What is the wear life of the components, and will they last given a large slurry configuration?

Given the importance of the mill discharge process, it is crucial that pumps are designed to withstand the harsh conditions of the slurry and have a long service life.

Recent advancements in technology have allowed for greater understanding of how particles behave within slurry mixtures, leading to the development of more efficient hydraulic passages. Here at Metso, we have leveraged Computational Fluid Dynamics CFDs and Finite Element Analysis FEA tools to design our latest mill duty pump. This modern design incorporates the most recent technological advances in the industry.

When selecting, you should consider the material used in its construction. A manufacturer with a range of options allows operations to adapt to changes in the application.

“Not all materials are perfect for every application, slurry composition along with the particle sizes and shapes, within the slurry dictate what material will be the most optimal,” says Diwakar. “With that in mind, does your manufacturer have options if your duty changes? Do you have rubber, metal, polyurethane or any other options that can be deployed for optimal performance? You always have to think ahead and ensure you’ve covered your bases.”

Inlet velocities are also crucial in mill discharge pump design, particularly for slurry class 4 applications. The reason for that is simple: Particles with lower velocities do less damage. Low inlet velocities reduce damage to the pump and ensure longer wear life. Thus, it is beneficial to select a pump that spins at a lower RPM (Revolutions per minute). With reduced inlet velocity at Best Efficiency Point (BEP), this ensures minimized impact damage from sharp, coarse and heavy solids.

Overall, the importance of design cannot be overstated when it comes to mill discharge pumps. The latest technological advances, materials, modularity, and inlet velocities are all critical factors to consider when selecting a pump that can withstand the demands of the mining industry and ensure a long service life.

Is it easy and cost effective to maintain?

Maintenance should always be part of selections when you’re comparing manufacturers, as mill pumps should be able to be serviced quickly and efficiently to minimize downtime.

One key factor in this regard is design. If the design is modular, you can maintain individual elements of the pump. Since a pump is a combination of a mechanical elements and a fluid containing elements, it’s beneficial if the two can be separated and maintained independently in different intervals.

There are a variety of advantages from having a pump which has a modular design and various wet-end material options, such as the opportunity for quick rebuilds and the advantage of combining various wet-end materials based on need. In terms of maintenance, you can change the whole pump out or just change the wet end out, depending on how the cycles are. An added benefit of this is the ability to synchronize your outages and maintenance schedules, as well.

After considering a variety of designs during development, Metso recognized the importance of a modular design in terms of adaptability, availability, safety and ease of maintenance.

“It’s always beneficial if you have a modular design, because then you can upsize the wet end with a little amount of piping changes, spool pipes, and more,” says Diwakar. “An operational tip from me is to always keep that re-size capability and flexibility when selecting a mill discharge pump – you won’t regret it.”

Can the pump be digitalized once technological advancements become available?

As technology advances, pumps are becoming more sophisticated. There is an increasing interest in implementing digitalization as this offers the advantage of predictive maintenance. It’s important to consider if your existing mill discharge pump can be integrated into a digital system, and what advantages this can provide.

One of the key advantages of digitalization is the ability to monitor the performance of the pump in real-time. Modern high-tech pumps often have assisted adjustments that can be made while the pump is still running, allowing for optimization of performance and minimized wear. Vibration accelerometers and temperature measurement devices are also commonly integrated into the bearings, providing valuable insights into the mechanical side of the pump.

"It's important to be able to use any advantages from the features available on the pump," says Diwakar. "Whether it's bearing assemblies with temperature and vibration sensors, alerts that can be set for undesirable operating conditions, assisted or automated nose-gap adjustment, or our slide-base option that allows for quick inspections and maintenance, there are unique features from each manufacturer – it's all about finding the right one."

Metso’s MD Series includes an innovation called the slide base, which allows for the suction and discharge piping to remain on the pump while the mechanical end can be moved backwards. This enables quick inspections and maintenance on the impeller or back liner while the pump is open.

As the mining industry continues to embrace digitalization, the ability to integrate mill discharge pumps into a digital system will become increasingly important. While it may not be possible with all existing pumps, those with advanced features and modular designs offer the greatest potential for integration. The benefits of predictive maintenance and real-time monitoring help to optimize performance and reduce downtime, providing significant cost savings long term.

Your partner for positive change

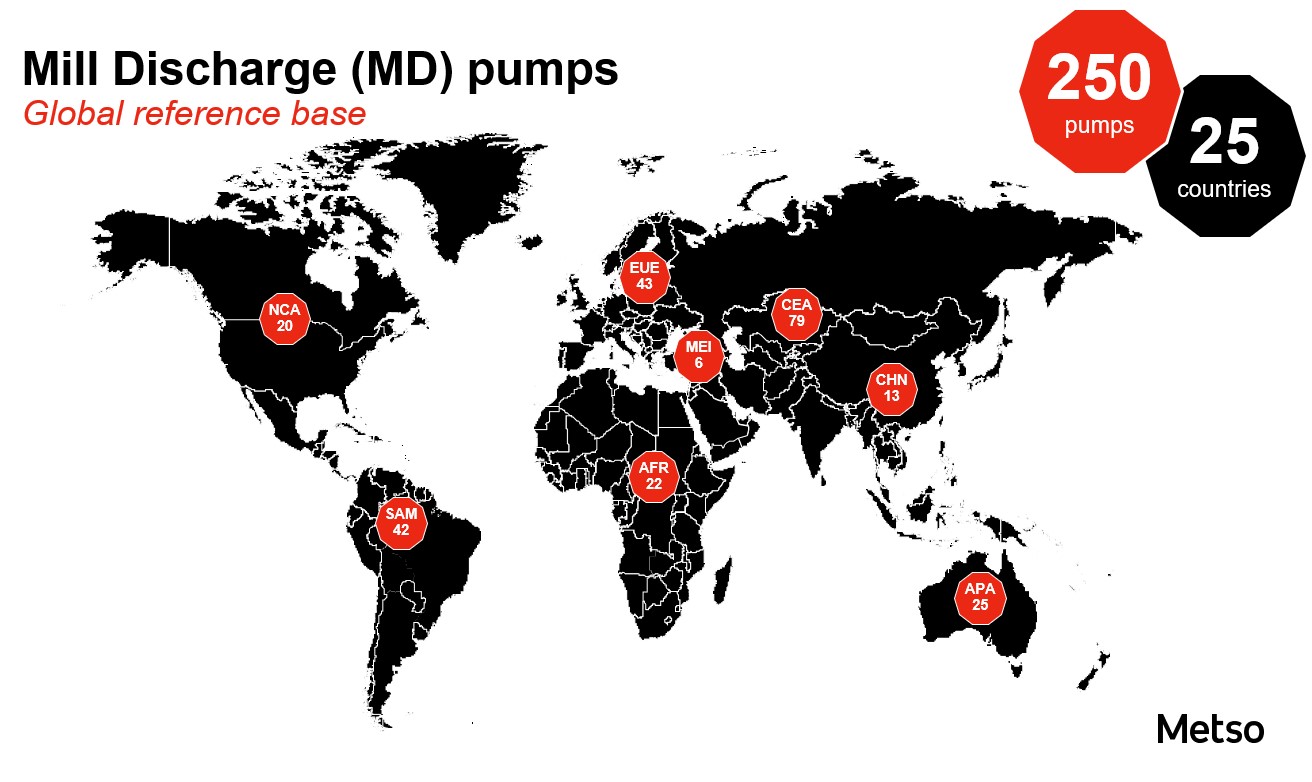

As the most recent development within the mill discharge pump market, the MD Series pumps boast the latest designs with all of the points discussed in this article taken into considerations as part of the design.

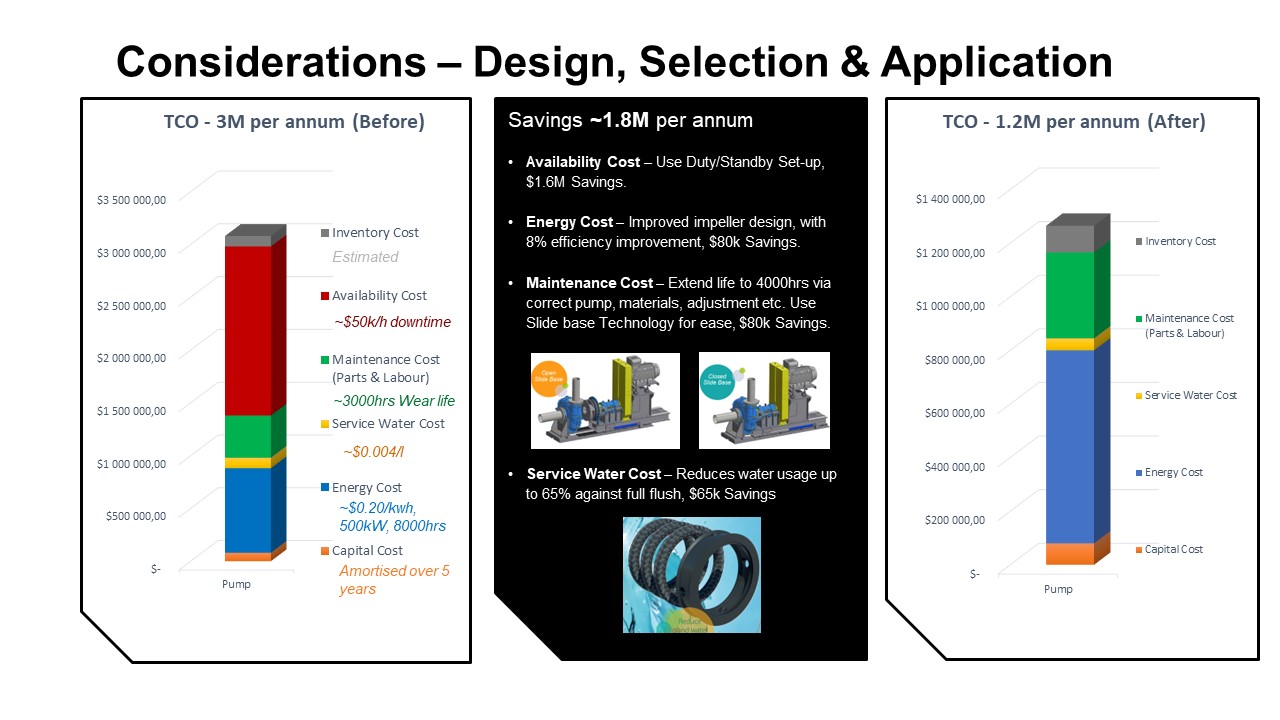

“Mill discharge pumps can affect your overall profitability, and every improvement is valid,” says Alan. “We look for improving in every step of the way so we can all maximize customer success and minimize total cost of ownership.”

With smart innovations at the forefront of development, the pumps are modular, thus being fast and safe to maintain. They have reduced inlet velocities of under 5.5 m/s, up to 4000+ hours of long service life, have the highest impeller aspect ratio in the industry, and they spin much slower, which directly correlates to speed of wear. In summary, the Metso MD Series Pumps will provide you with the lowest cost of ownership – which is, ultimately, what all operations are after.

“With the MD series, we aim to be the partner for positive change,” says Diwakar. “With that in mind, we have gone back to the drawing board. We have implemented the latest technologies to find the most premium solution for our customers. Together, we can optimize your success and keep your profit at a maximum.”