- Increased throughput either in tons per hour (tph) or volume (m3/h)

- Changing ore conditions such as lower grades or smaller particle size distribution (PSD)

- Changes in environment and social license to operate

Cumulative effect of upstream capacity improvements

The number one driver for thickener modernization is increased capacity. Often incremental increases occur over the life of a plant and it is not immediately recognized the impact this may have on thickener performance. When a plant embarks on an efficiency drive which results in a small 1-3% increase and the cumulative effect of this on thickener performance is not easily seen, as each change only marginally impacts thickener performance. Focus in these improvement projects is often upstream at the mills, leach or flotation circuits. However, when viewed as whole over a 10-20 year period these 'efficiency' gains can amount in throughput increases of 20-50%. The resulting decrease in underflow (UF) density, increasing flocculant consumption and torque trips are not recognized as deviating from the design by rotating and changing plant staff who may not be aware of its original design parameters.

Changed ore conditions

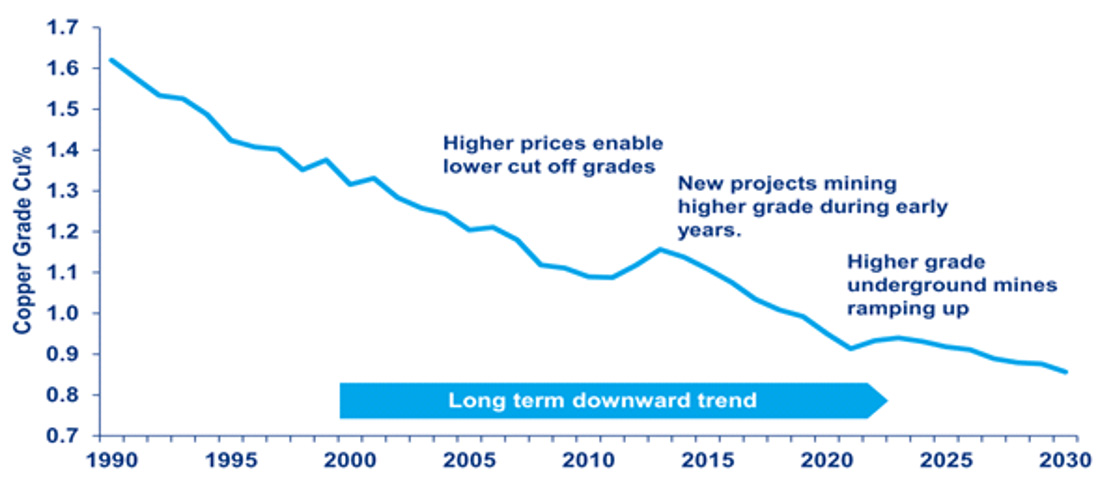

The second major driver for modernization of thickeners is changed ore conditions. It is well established that mine operators are processing ever-lower grades of mineralization (refer figure 1). This occurs when easy to mine, high value targets are exhausted and the ore body properties change. While also contributing to the push for higher throughput to maintain plant output and adequate Return-On-Investment (ROI), these lower grades are associated with smaller PSD. Smaller PSD has a direct impact on the settling characteristics of the solids materials and require more tightly tuned feed conditions and efficient flocculation to obtain the desired outcomes.