What triggers R&D work in practice?

In general, existing challenges or obstacles lead to new ideas and innovations. We are also continuously looking for ways to improve our products proactively by carefully identifying our customer needs versus our offering and value proposition capabilities.

New ideas can come from any party in our network, internally or externally. Usually the wildest ideas are born in cross-functional teams, which consist of product specialists as well as other functions. We want to make sure that our representatives can be approached quickly and easily in order to implement promising ideas.

R&D is strongly related to business and product strategy as an enabler. Product and development portfolios are constantly being examined with a magnifying glass to identify and fill any gaps and to reach the next level in our offering. We work in close cooperation with our metallic and rubber supply chains and external partners in selected technology fields. Key competence areas are maintained and developed inhouse.

What are the most prominent needs driving the development of mining consumables at the moment?

The customer is the most important influencer when we think about the priority of different development targets: safety, increased uptime, lower maintenance costs and maximized throughput. There may be variation in the objectives depending on the customer’s process and industry. However, the safety aspect is present in all the solutions we provide and is the starting point for all our work.

Environmental challenges are present and will be there for the rest of our lives and those of the following generations. The global aim to reduce scope 3 emissions—such as goods, services, and transportation—have been notified and we are working seriously to reduce the carbon footprint of manufacturing, recycling and in customer operations via our wear part solutions. For example, with optimized liner design, you are able to make a difference to the power consumption and throughput of the equipment. Notable increase in wear life means directly fewer emissions in the manufacturing of liners. Cost per produced ton is one thing and CO2 per produced ton is another. Our sustainability vision for 2025 aims to bring new environment-friendly products and solutions to market globally.

We are constantly working to optimize customers’ wear part design according to specific targets and operating conditions. Our in-house developed simulation tools allow us to predict the performance of the customized liners extremely accurately, which ensures that we deliver the gains we promise. This reduces the time to market as less prototyping and physical testing is needed to provide an optimal solution.

What has Metso done lately in this field?

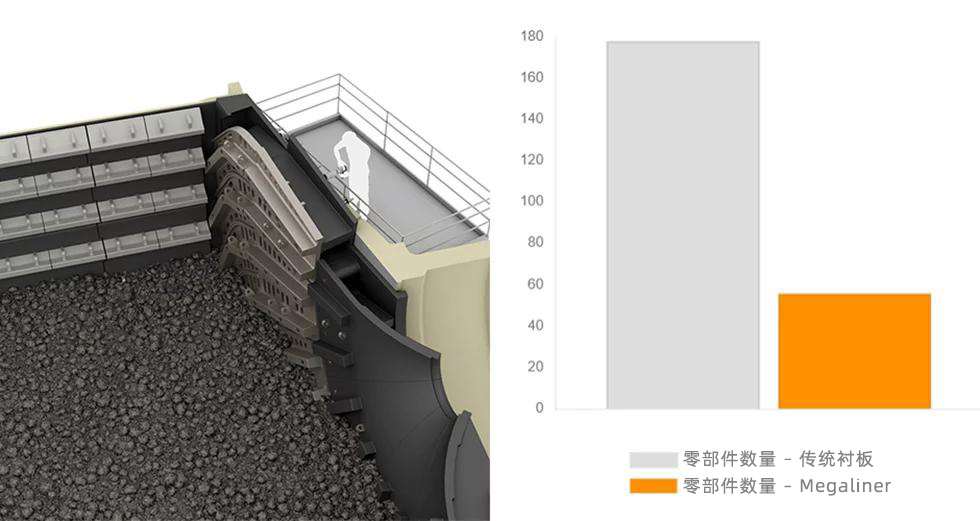

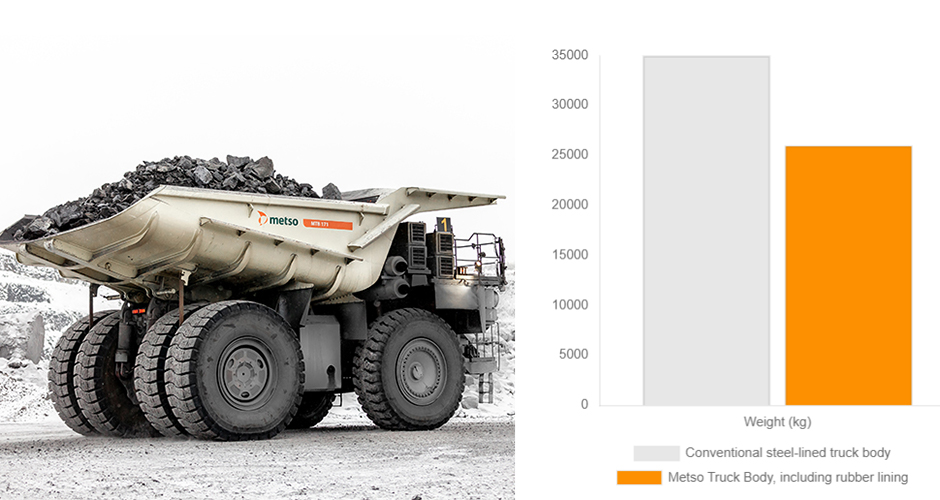

Our recent innovations include designs, new materials, manufacturing methods and digital tools. Some shining examples are the new Megaliner™ for grinding mill discharge systems and the Metso Truck Body for mining trucks and dumpers that have been recently launched with success. These solutions are new to the market and provide benefits which cannot be achieved with previously known technology.

The Megaliner™ for discharge systems integrates dischargers, grates, lifter bars, and filling segments in one unit. The number of components used is reduced by as much as up to 70% compared to traditional solutions. This can cut installation time in half and decrease critical downtime notably and increase safety.