Critical equipment is in constant use and in need of regular upkeep at mines around the globe. Planning around scheduled shutdowns is crucial to ensure the equipment keeps producing. However, due to production schedules and operational pressure, maintenance can be deferred, leading to critical equipment being overlooked. This can eventually result in equipment failure, which impacts production. Unplanned maintenance can also halt downstream processes, further affecting throughput.

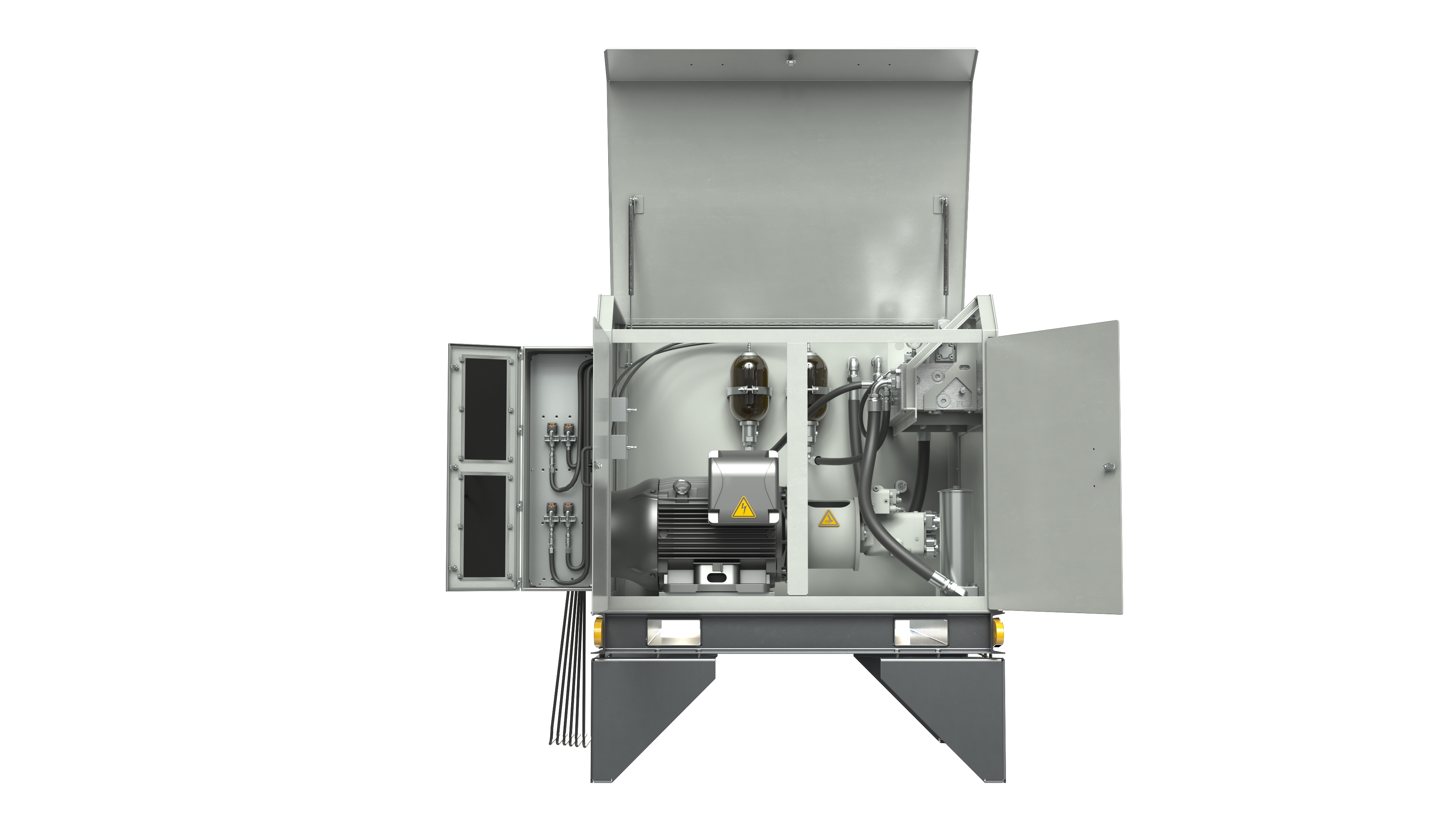

The hydraulic power unit (HPU) is essential for your crushing operation as it controls the pump and motor group that pressurizes and depressurizes a crusher’s hydraulic circuits, allowing for adjustment of the crusher settings and maintenance on the crusher components. Although critical, it is often one of the pieces of equipment that gets overlooked. Over the years, contamination, wear and age result in failures and leaks. As the power unit ages, finding spare parts or replacements becomes increasingly difficult. Constant improvements in electronics design often require a search for replacements or a full update of components to align with modern offerings. This can be frustrating and cause unplanned downtime and lost production if not addressed. This challenge is becoming more critical as knowledgeable crusher experts retire from the industry, making it harder to find qualified replacements. Metso has collaborated with suppliers, customers and support staff to address these challenges by introducing a 5th Generation MP HPU with new functions to increase reliability, reduce maintenance and improve safety.