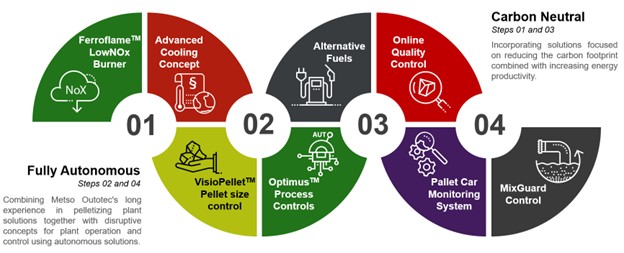

However, reducing the carbon footprint of mining and pelletizing will be equally important to achieve globally agreed targets, while the shift towards direct reduced iron (DRI) production requires more highly beneficiated ores and higher-quality pellets than the traditional blast furnace (BF) route. To support this transition of the industry, Metso Outotec has launched the NextGen™ Pelletizing concept, following a clear product vision: The pellet plant of the future is carbon neutral and fully autonomous.

Metso Outotec’s NextGenTM Pelletizing

The concept follows a modular approach that will see more modules in future and is available for new greenfield installations, but also as upgrade for existing travelling grate pelletizing plants.

Focusing on the carbon-neutral production of pellets there are three main sources of CO2 in the pelletizing process:

-

Solid fuel addition in the concentrate mix

-

Burner fuels

-

Electricity, mainly for the process gas fans

While removing solid fuel from the raw mix for hematites requires finding “green” substitutes, looking at ways to increase fuel and energy efficiency and to burn suitable alternatives to fossil fuels has been the main driver for our developments.

Only recently Metso Outotec launched its own FerroFlame burner family for travelling grate pelletizing plants, for standard and low NOx applications and we are actively developing a hydrogen burner utilizing the same patented LowNOx technology. At the same time, the Advanced Cooling concept is providing more fuel efficiency and gentle cooling of pellets by further recuperating parts of the off-gas.

The NextGen™ Pelletizing plant also provides the option for advanced burner configurations in a re-designed indurating hood, which improves the temperature distribution across the width of the bed, providing more pellets with the same temperature history throughout the process and hence more consistent quality.

At the same time, the increasing quality demands of DR-grade pellets require more stable operations in a narrower operating window and thus higher-level process control where the need for human intervention is minimized.

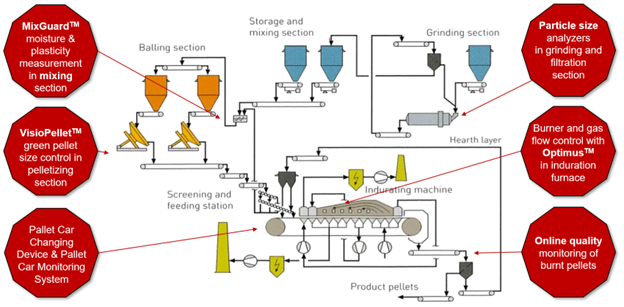

Here, advanced process control (APC) is of paramount importance. The already available Metso Outotec Optimus advance process control system optimizes the processes in the induration furnace by means of pressure, temperature, and fan-speed control.

To enable holistic optimization of the performance of the pelletizing process, all relevant factors for energy efficiency, plant production, and pellet quality throughout the entire process need to be taken into account. The main factors are the concentrate quality, the quality of the mixing step and the green pelletizing, the bed distribution on the pallet car, and the induration process in the furnace. The final aim is to control the entire process based on online measurement of the quality (strength and metallurgical composition) of the burned pellets.