Sensor-based sorting technology

Sensor-based sorting has been around since the 1970’s. In the early days mainly radiometric and photometric sensors were used to distinguish characteristics of materials. As it is common with new technology it was very expensive, and computing performance was highly limited making it often not economic viable. The information revolution at the turn of the millennium boosted computing power, making it cheap and available. Today data reconciliation, validation and analyzing does not limit the sorting process any more. The focus on research and development is now on new sensors and sensor accuracy with the aim of improving detection accuracy.

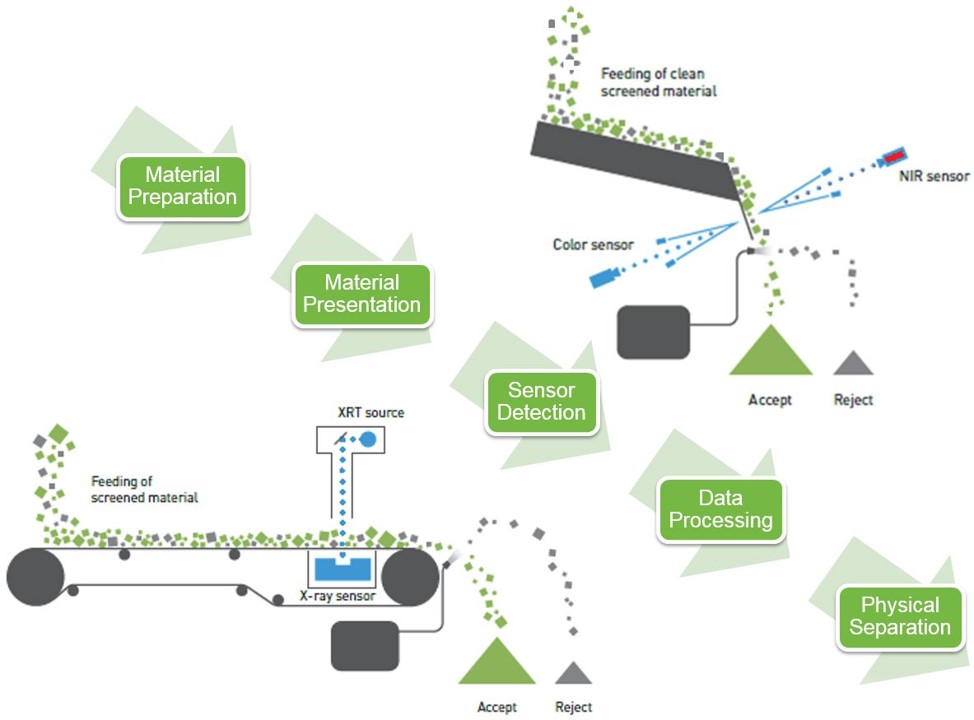

Outotec provides pneumatic sensor-based sorting machines for pre-concentration in the mining and minerals processing industry, via our partnership agreement with Tomra Mining. Different sensor and machine types cover a vast selection of ore and mineral types. All machines are built with the same three principles: material presentation, data collection by sensors, and separation. Material is presented to the sensors as a monolayer of liberated particles. Different sensor types analyze every single particle, and the decision of accepting or rejecting is made within 30 milliseconds. Physical separation of particles is achieved by altering the particle trajectory with precise air jets into the product or waste chutes.